Ball-Turnig-Attachment

Machinelist: Ball-Turnig-Attachment

Ball-Turnig-Attachment

- IproMac e.K.

- Ennertsweg 38 b

- 58675 Hemer

- Deutschland

-

+49 (0) 170 27 32 014

-

w.schneegass@ipromac.de

www.ipromac.de

#2075-9026 · Ball-Turnig-Attachment

ARGUS - FLOWSERVE - Kugelbearbeitung - - 2000 - Siemens 840 D

Technical details

Ball machining center Special facility for balls 100 to 400 mm A viewing and demonstration is possible by appointment.

CNC Turning- and Milling Center

- Mager & Wedemeyer

- Europaallee 24a

- 28309 Bremen

- Deutschland

-

+49 (0)421 - 33616-100

+49 (0)421 - 33616-169 -

jhagedorn@mager-wedemeyer.com

www.mager-wedemeyer.com

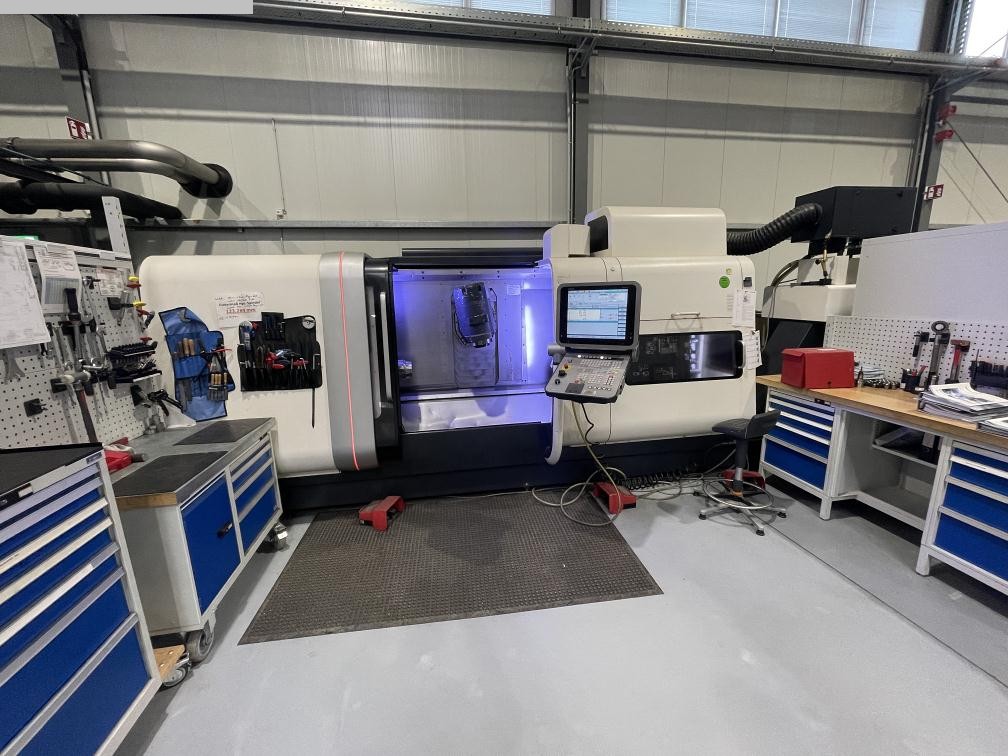

#1023-09208F · CNC Turning- and Milling Center

MAZAK - Integrex j-200 x 1000 - - 2021 - Mazatrol Smooth G

Technical details

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03991 · CNC Turning- and Milling Center

TAKISAWA - LA 250 YS - - 2017 - FANUC 31 ITB

Technical details

High Performance CNC Turning- and Milling Center with Y - Axis Chipconveyer, Counterspindle, driven tools, Y - Axis for eccentric Drilling and Milling works + - 60 mm C-Axis, screw brake, partcatcher, 3 driven tools as accessories, 10 static holder as accessories, , Toolsystem with one collet each for Main - and Subspindle, Tool Eye Measurement, Part catcher and part conveyer WHITOUT BAR LODER

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100552 · CNC Turning- and Milling Center

Goodway - Typ: SW 32 - - 2017 - Fanuc

Technical details

Solid slant bed esures the lathe´s accuracy stability even in the situation of heavy cutting. Wide span rectangle sliding guides possess strong ability of anti-bending, anti-twisting and anti-overturning. Applied abrasion-proof material of low friction coefficient and cooperated with the optimum positioning accuracy even in rapid feeding. Straight line rolling guides meet the requirements of high speed and high efficiency, reduce friction resistance and thermal deformation, improve machining accuracy and ensure long period stability of machining accuracy. Due to fact that Servomotors of X-axis and Z-axis are connected directly with precision ball screws through can be obtained elastic coupling and obtained high precision.

Datasheet

Request / Contact

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-90351 · CNC Turning- and Milling Center

DMG-GILDEMEISTER - CTX beta 1250 TC - - 2014 - Siemens 840d Solutionline

Technical details

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20313 · CNC Turning- and Milling Center

MAZAK - Integrex i-100S - - 2013 - Mazatrol Matrix 2

Technical details

5-axis simultaneous machining - CNC control Mazatrol Matrix 2 - Main & counter spindle - 6" chuck (B206) - Tool changer (36-fold) HSK - Coolant system - Chip tray

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2323 · CNC Turning- and Milling Center

GILDEMEISTER - CTX Beta 800 - - 2012 - Siemens 840 D

Technical details

CNC turning and milling center in good condition with driven tools, C and Y axis, subspindle and CNC control Siemens 840 D. Operating hours according to the attached photo from February 8, 2024 The hours may increase as the machine is currently still in use. Max. workpiece diameter 410 mm Max. workpiece length 800 mm Max. travel X-axis 300 mm Max. travel Y-axis +/- 50 mm Max. travel Z-axis 850 mm Turning diameter over cross slide 250 mm Main spindle drive power 65 kW Spindle bore 75 mm Spindle speed of the main spindle 4000 rpm. Spindle speed of the counter spindle 5000 rpm. Equipment and accessories: Chip conveyor Coolant system with paper belt filter Oil mist extraction system Electrical control cabinet with air conditioning (tropical package) 3-jaw power chuck on main and subspindle Basic equipment of tool holders Documentation/Manual

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2024081 · CNC Turning- and Milling Center

MORI SEIKI - NZX 2000/800 SY2 - - 2012 - MAPS

Technical details

In our estimation, the machine is in very good condition and can be viewed live by appointment. technical features: - 2 pcs. Revolvers, 16 places each - counter spindle - driven tool stations - 2 pcs. Y-axis - Extensive accessories included in the scope of delivery Accesories: - bar loader *** Changes and errors in the technical data and information as well Subject to prior sale!***

Datasheet

Request / Contact

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-619 · CNC Turning- and Milling Center

MORI-SEIKI - NT 4250DCG/1500S - - 2008 - MSX-701 III

Technical details

Rapid traverse rate (X1, Z1 Axis) 50 m./min. Rapid traverse rate (X2 Z2 Axis) 30 m./min. Rapid traverse rate (Y Axis) 30 m./min. Rapid traverse rate spindle 2 ZS 30 m./mm. Rapid traverse rate B axis 40 rpm Rapid traverse rate C axis 250 rpm Spindle 1: Speed 4.000 rpm Number of speed ranges 2 Nose JIS A2-8 C axis in spindle 1 I Min indexing increment spindle 1 0.0001º Power 26/22 kW Max torque 724 Nm 3-jaw automatic chuck KITAKAWA B-212 A8 Chuck size 304 mm. Chuck hole 91 mm. Chuck speed 3300 rpm Spindle 2: Speed 4.000 rpm Through-spindle hole 91 mm. Nose JIS A2-8 C axis in sub- spindle 1 Min indexing increment spindle 2 0.0001º Power 26/22 kW Max torque 724 Nm 3-jaw automatic chuck KITAKAWA B-212 A8 Chuck size 304 mm. Chuck hole 91 mm. Chuck speed 3300 rpm Tool Spindle Direct drive spindle INCLUIDO/INCLUDED B axis indexing time 0.65s Min B-axis indexing increment 0.0001º Max B-axis indexing speed 100 min-1 Taper hole of rotary tool spindle Capto C6 Max Speed of the Head 12.000 rpm Milling Motol Power 18.5/11 kW Spindle torque 120/44 Nm Tool clamp 12.000 N Automatic tool changer: Tool system Capto C6 ATC positions 100 Max Tool diameter 70 mm. Mas tool diameter without 140 mm. Max tool length 400 mm. Max tool weight 8 k Tool-to -tool change 1.25 s

- Isabelle Knops

- Opladener Str. 126

- 40789 Monheim am Rhein

- Deutschland

-

+49 (0)2173-4999611

+49 (0)2173-8546560 -

isabelle.knops@isabelleknops.com

www.isabelleknops.com

#2013-0005 · CNC Turning- and Milling Center

WFL - M120 MILLTURN x 5000 - - 2008 - Siemens 840D pl

Technical details

Multifunctional Turning-Boring-Milling Centre / Brand: WFL Type: M120 MILLTURN x 5000 / Year of construction: 2008 The machine can be inspected by appointment under power. Very well-maintained used, functional condition. TECHNICAL DATA: - CNC Control: Siemens 840D Working area: - Nominal width/turning length: 5.000 mm - Swing diameter over top slide: 1.140 mm - Swing diameter via telescope left/right: 1.160 mm - Swing diameter over setting block slide: 1.150 mm - Height of turning centre over floor: 1.555 mm - Connected load: 145 kW/162 kVA - Machine weight: approx. 56 tons - Main machine dimensions (Length/Width/Height): approx. 15.497* x 5.342 x4.277 mm ACCESSORIES/EQUIPMENT: - Boring bar vibration-damped, brand: Sandvik - Electrostatic suction, brand: UAS - Steady rest, brand: SMW Autoblock - Turning-boring-milling unit - Tool magazine: 90 positions - Electronic hand wheel - Coolant device - Infrared measuring probe, brand: m&h - Chip conveyor (paper belt filter), brand: POLO - Documentation - CE marking There is no guarantee for correctness and completeness of the technical details and accessories. - Subject to prior sale - Detailed technical data sheet and information on equipment available on request.

- AS Maschinenhandel

- Welserstr. 10e

- 51149 Köln

- Deutschland

-

+49 (0)22031864856

+49 (0)22031864857 -

mail@asmaschinenhandel.de

www.asmaschinenhandel.de

#2044-100108 · CNC Turning- and Milling Center

DOOSAN - Puma MX2500 LST - - 2008 - Fanuc 18 iT-B

Technical details

- MWB GmbH & CO. KG

- Parkstraße 12

- 09456 Annaberg-Buchholz

- Deutschland

-

+49 3733 5068501

-

info@mwb-machinetrade.com

https://www.mwb-machinetrade.com

#2069-7647 · CNC Turning- and Milling Center

CHIRON - Mill 2000 - - 2008 -

Technical details

Control - Siemens Sinumerik 840D Powerline NC swivel head - ± 100° Loading and unloading station for tools Production package with HH pump - PF50 / FKA 900 70 bar HD pump Flush gun for Mill 2000 Rotating viewing window Glass scales for lineal system Ethernet connection Barcode reader

- Klaus Rosenboom GmbH

- Oppenheimer Str. 19

- 28307 Bremen

-

+49 (0) 4 21 / 33 30 10

+49 (0) 4 21 / 48 70 45 -

info@rosenboom-wzm.de

www.rosenboom-wzm.de

#1021-52311 · CNC Turning- and Milling Center

GILDEMEISTER - CTX 210 V3 - - 2007 - Siemens 840 D Shop Turn

Technical details

CNC lathe with driven tools and barfeeder - collet chuck E 173 - chipconveyor - Siemens Shop Turn - dialog programming Shop Turn - parts catcher - short bar magazine IEMCA KID 70

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17898 · CNC Turning- and Milling Center

INDEX - G200 - - 2007 - C200-4D INDEX

Technical details

Main (S3) and counter spindle (S4) with tailstock function hydraulic clamping cylinders in the main and counter spindle S3 spindle 42mm/13kW/7000 rpm S4 spindle 42mm/13kW/7000 rpm (electric shaft) S1;S2;S3;S4 as C axis 2 tool breakage sensors Turret 1 (X1;Y;Z1) with 14 stations / driven / VDI25 Turret 2 (X2;Z2) with 14 stations / powered / VDI25 Z4 axis counter spindle Z5 axis portal removal device Index conveyor belt 1 Transmit / Tracyl in CH1/CH2 Hainbuch collet system UNIMAG interface Short bar loader Breuning IRCO RBK 10012 built in 2007 chip conveyor Coolant device

Datasheet

Request / Contact

- Marcels Maschinen AG

- Anthoptstrasse 11

- 8222 Beringen (Schaffhausen)

- Schweiz

-

(0041) 44 872 3400

(0041) 44 872 3403 -

info@marcels-maschinen.ch

http://www.marcels-maschinen.ch

#1065-5003 · CNC Turning- and Milling Center

HAAS - SL30-THF - - 2007 - HAAS

Technical details

Datasheet

Request / Contact

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02927 · CNC Turning- and Milling Center

Traub - TNK 36 - - 2005 - Traub TX 8i

Technical details

CNC automatic lathe Traub TNK 36, year 2005, with bar feeder FMB turbo 5-42 This turning-milling centre is in a very good condition and equipped with 2x Y- axes and driven tools on 3 tool carriers. Tool carrier 1 = turret 12-fold driven, Y-axis +/-20mm Tool carrier 2 = front attachment 5 stations (4 driven) Tool carrier 3 = rear station 5 stations (4 driven)Y-axis +/-50mm Knoll chip conveyor (hinged belt). Cooling lubricant device with main pump for turret. and 30 bar high pressure pump for front and rear attachment. Resy cooling lubricant cleaning system flow filter approx. 25 micron. FMB bar feeder turbo 5-42 for 3m bar length, plus 15 + 25 + 36mm channels and loading bars. Accessories for TNK 36: for turret 25 fixed tool holders 10 driven tool holders for front+rear: 16 fixed tool holders 6 driven tool holders Clamping devices for HSP/GSP: 50 Hainbuch expansion chucks SK 6970 ZW/G

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1672 · CNC Turning- and Milling Center

DMG - CTX 420 - - 2005 - SIEMENS 840D

Technical details

CNC Turning- and Milling Center | DMG - CTX 420 Additional equipment: - C-Axis with Driven tool positions - Y axis Scope of delivery / Accessories: - 1x jaw chuck, - 1x collet chuck, - 10x rotary holders, - 8x normal angle holders, - 3x driven angle holders, - 3x driven forehead holders The machine has only 9.931 H spindle hours. The machine is in a well-maintained condition and can be inspected at any time under power. A machine video from the production plant will be shared on request. Technical data of the machine will follow soon. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: CTX420 | CTX-420

- MW-MACHINES

- Dorf 9

- 4133 Hofkirchen

- Österreich

-

+43 (0)66718068977

- -

info@machines-mw.at

machines-mw.at

#2077-20018 · CNC Turning- and Milling Center

WFL - Millturn M100 / 3000 - - 2005 - Sinumerik 840 D

Technical details

Three-jaw chuck ø400 (hydraulically clamped) Three-jaw chuck ø630 (hydraulically clamped) Face plate ø800 Spindle bore depth from chuck approx. 900mm Lynette 1: ø30 - ø245 Lynette 2: ø125 - ø460 Tailstock Five-axis angle head 72 magazine plates (max. length 800 mm, max. diameter 250 mm, 25 kg) Self-travelling machine door Crashguard Studio" software for programming the machine at an external workstation

- ADEM MASCHINEN GMBH

- Karl-Benz-Straße 1

- 40764 Langenfeld (Rheinland)

- Deutschland

-

+49 (0) 2173- 287 77 07

+49 (0) 2173- 287 77 05 -

adem-maschinen@t-online.de

www.adem-maschinen.com

#2000-376 · CNC Turning- and Milling Center

DOOSAN - PUMA MX 2000 ST - - 2005 - ---

Technical details

Datasheet

Request / Contact

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

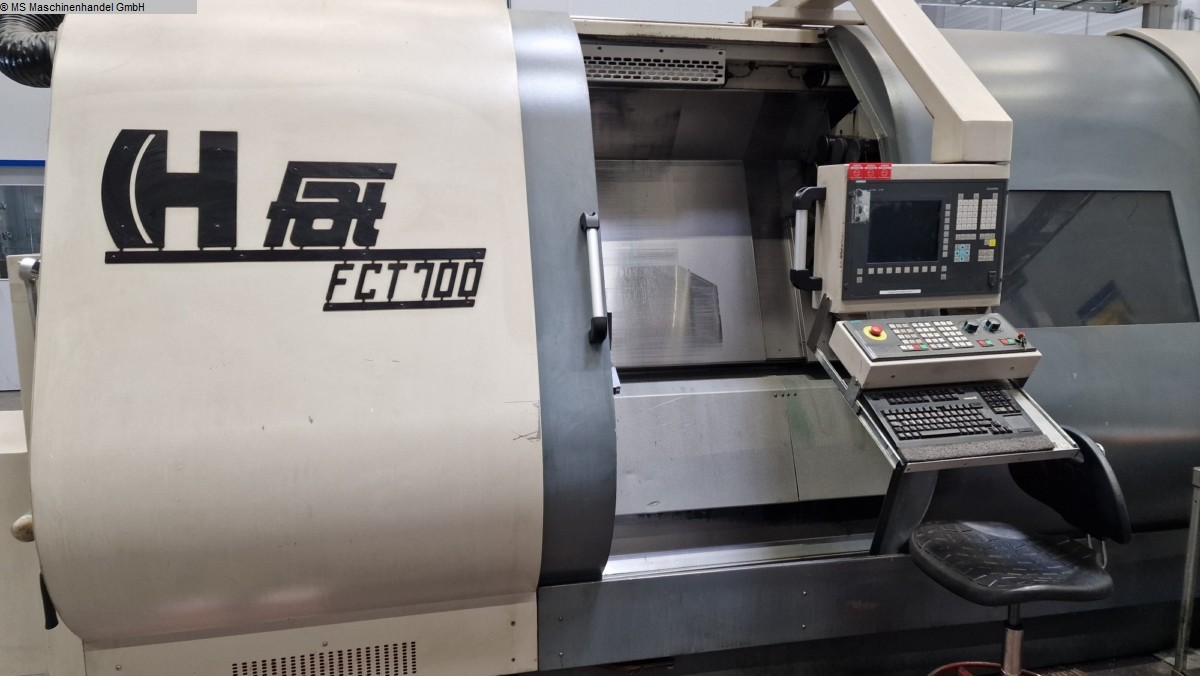

#2034-163 · CNC Turning- and Milling Center

FAT - FCT-700 - - 2005 - SIEMEMS 840 D Shop Turn

Technical details

This FAT Haco FCT-700 CNC lathe is in very good condition and available immediately.

.1072-20344-1906202311133115.jpg)

- Kirchgeorg Werkzeugmaschinen

- Frankfurter Straße 141

- 63303 Dreieich-Sprendlingen

- Deutschland

-

0049-(0)-6103-9909-0

0049-(0)-6103-9909-50 -

info@kirchgeorg.de

www.kirchgeorg.de

#1072-20344 · CNC Turning- and Milling Center

GILDEMEISTER (teilueberholt) - CTX 420 linear/CNC-Heidenhain - - 2004 - Data Pilot 4290 HEIDENHAIN

Technical details

- Serial-No.: 02260003251 - Machine ON: 19.039 h - Programm ON: 2.676 h - control: HEIDENHAIN Data Pilot 4290 - new main spindle bearings - Z-Axis ball screw reconditioned incl. new bearings - electronic hand wheel - C-Axis / driven tools - chip conveyor - coolant equipment - machine lamp

Datasheet

Request / Contact

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-2753 · CNC Turning- and Milling Center

MAZAK - Integrex 200-III S - - 2004 - Mazatrol Fusion 640MT PRO

Technical details

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9126 · CNC Turning- and Milling Center

GILDEMEISTER - CTX 310 V3 - - 2003 - 840 D Siemens

Technical details

CNC Turning- and Milling Center GILDEMEISTER - CTX 310 V3 - incl. bar loading magazine IRCO Breuning - incl. 2x collet chucks - incl. 2x jaw chuck including various clamping jaws - various VDI30 rotary holders - various reducing tubes - approx. 20x collets 173E - Pressure sleeve for collets 185E (for bars up to Ø50) - 11x collets 185E

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de