Planer-Type Milling M-C - Double Column

Machinelist: Planer-Type Milling M/C - Double Column

Planer-Type Milling M/C - Double Column

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

#2034-170 · Planer-Type Milling M/C - Double Column

CORREA - PANTERA - - 2012 - HH iTNC 530

Technical details

This portal milling machine is in good condition and can be inspected by arrangement be inspected under power at the seller's premises. Description: - 80-position tool changer with 40 positions ISO SK-50 / 40 positions HSK-63A - 4-fold automatic head changer - 2 pieces orthogonal milling head OAD with: --> Tool holder ISO SK-50 --> Spindle speed: 20-6000 rpm --> 46kW drive power (100% ED S1) - 1 piece 2-axis fork milling head E5E (CAC II) with: --> HSK-63A tool holder --> swivelling range C-axis: +/- 200° --> swivelling range B-axis: +/- 100° --> drive power 37kW --> Spindle speed max. 24000 rpm, ***** Spindle DEFECTIVE !!! ***** 1 vertical spindle F-400 --> Spindle speed 4000 rpm --> drive power 25kW IKZ 38bar with paper belt filter 2 chip conveyors (lengthwise channelling belt conveyor 1 cross conveyor Heidenhain longitudinal measuring rods in all three axes Z-axis with 4-fold linear guide Wireless measuring probe M&H 20.41 Multi BRANKAM machine protection system CMS-100 (collision protection) Working area cover (roof) can be opened at the rear and front BLUM tool measurement Heidenhain HR 550 FS radio handwheel X and Y-axis drive via rack and 2 pinions Z-axis drive via ball screw

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-90330 · Planer-Type Milling M/C - Double Column

AWEA - CNC - LP 3016 YF - - 2011 - Fanuc 18i MB

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100460 · Planer-Type Milling M/C - Double Column

CORREA - FP50/80 - - 2010 (überholt in 20 - HEIDENHAIN TNC-530

Technical details

Year of manufacture: 1990 retrofitted: 2014 Numerical control: HEIDENHAIN TNC-530 Traverses of axis X Axis traverse: 5000 mm Y Axis traverse: 3300 mm Distance between columns: 2700 mm Z Axis traverse: 1000 mm (500/1500) Milling head Head type: Universal manual Tool clamping system: Hydraulic Taper nose: ISO 50 DIN 69871 Speed range: 20 - 4000 rpm Spindle power: 42 kW Dimensions Table dimensions: 5000 x 2000 mm Number of T slots: 9 T slots dimensions: 22 mm Feedrates Feedrate: 5000 mm/min Rapid feedrate (X / Y,Z): 7200 / 5000 mm/min Weight and dimensions Maximum weight on table: 25000 Kg Machine weight: 60000 Kg Machine dimensions: 12700 x 5420 x 6033 mm Accesories Ec Guarding Electronic handwheel: HR-410

Datasheet

Request / Contact

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-724 · Planer-Type Milling M/C - Double Column

CORREA - FP 50-80 - - 2010 - HEIDENHAIN iTNC-530

Technical details

- 5 AXIS BRIDGE TYPE MILLING MACHINES Max height table to underside bridge 2.100 mm Min/max distance table to spindle 500-1.750 mm Rapid Feed (X Axis) 10.000 mm/min Rapid Feed (Y,Z Axis) 12.000 mm/min Max. Working Feed 7.000 mm/min Automatic head C5 E INCLUDED B-Axis head swivel ± 190º C Axis head rotation ± 360º Spindle taper ISO 50 Spindle speed 4.000 r.p.m. Spindle Torque 718 Nm Portable Handwheel INCLUDED Thermal growth compensation system INCLUDED

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-90331 · Planer-Type Milling M/C - Double Column

AWEA - CNC - SP 3016 - - 2006 - Fanuc 18i MB

Technical details

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-450 · Planer-Type Milling M/C - Double Column

NICOLAS CORREA - RAPID 50 - - 2005 - FIDIA C20

Technical details

-Automatic head UAD II -Tool clamping Hydraulic -Head 2 – Vertical mandril INCLUDED -2 longitudinal chip conveyors -1 cross chip conveyor -Laser tool presetter

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03824 · Planer-Type Milling M/C - Double Column

UNISIGN - UP 6000 - - 2005 - Siemens

Technical details

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

#2034-151 · Planer-Type Milling M/C - Double Column

WALDRICH-COBURG - Valutec - - 2005 - SIEMENS 840D

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100240 · Planer-Type Milling M/C - Double Column

Johnford - DMC-8500 - - 2005 - SIEMENS 840D

Technical details

Datasheet

Request / Contact

- SK Maschinen-Service GmbH

- Tackweg 4

- 47918 Tönisvorst

- Deutschland

-

02151 79350

02151 793535 -

info@sk-maschinen.de

www.sk-maschinen.de

#1038-90333 · Planer-Type Milling M/C - Double Column

HARTFORD - HB 3190 A - - 2004 - Fanuc 18 M

Technical details

- Intermach BV

- lange voor 71

- 8316BC Marknesse

- Niederlande

-

+31 (0)653235637

-

info@intermach.nl

www.intermach.nl

#2050-1110051 · Planer-Type Milling M/C - Double Column

CORREA - rapid 5 - - 2004 -

Technical details

Stock number 1110051 Machine type CNC Portal milling machine Make CORREA Rapid type 50 Year of manufacture 2004 Control type HEIDENHAIN Table size (mm) 5000 x 2000 mm X out (mm) 5000 mm Y-off (mm) 3100 mm Z-off (mm) 1200 mm Table load Max 15 ton Speed (RPM) Max 18,000 Tool holder HSK 63 Gesamtleistung(kW) 20/27 Length (mm) 15000 Width (mm) 6200 Height (mm) 6000 Weight 65 ton Additional information Tool changer for 24 tools 5-axis gesteuerd

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100461 · Planer-Type Milling M/C - Double Column

CORREA - PANTERA - - 2003/2024 - SIEMENS 840 D

Technical details

Year of manufacture: 1990 retrofitted: 2014 Numerical control: HEIDENHAIN TNC-530 Traverses of axis X Axis traverse: 5000 mm Y Axis traverse: 3300 mm Distance between columns: 2700 mm Z Axis traverse: 1000 mm (500/1500) Milling head Head type: Universal manual Tool clamping system: Hydraulic Taper nose: ISO 50 DIN 69871 Speed range: 20 - 4000 rpm Spindle power: 42 kW Dimensions Table dimensions: 5000 x 2000 mm Number of T slots: 9 T slots dimensions: 22 mm Feedrates Feedrate: 5000 mm/min Rapid feedrate (X / Y,Z): 7200 / 5000 mm/min Weight and dimensions Maximum weight on table: 25000 Kg Machine weight: 60000 Kg Machine dimensions: 12700 x 5420 x 6033 mm Accesories Ec Guarding Electronic handwheel: HR-410

Datasheet

Request / Contact

- IMZ Maschinen Vertriebs GmbH

- Marie-Curie-Straße 19

- 73529 Schwäbisch Gmünd

- Deutschland

-

0049 (0) 7171 987130

0049 (0) 7171 9871329 -

info@imz.de

www.imz.de

#1075-6925 · Planer-Type Milling M/C - Double Column

WESTPHAL - Techline M 510 - - 2003 - NUM 1060 W

Technical details

Use: e.g. for processing aluminum panels, drilling profiles, advertising (signs milling, etc.), mold construction (prototypes) and processing of light steel frames / -beams using HSC milling The vertically arranged high-frequency milling spindle for automatic Tool change is mounted in a fork head on the Z-axis plate. The Spindle can be moved with the fork head in 2 NC axes, in the A axis and the C-axis. The vertical movement is carried out via the Z-axis. Liquid cooling via a cooling unit. Tool magazine: moving plate changer in the potal, outside the Work area Minimum quantity cooling and lubrication system MQL The machine table consists of milled aluminum plates 8 bar compressed air, clean, dry, oil-free, including pressure intensifier 10- 12 bar to express the tool Feed rates in rapid traverse / working step: X-axis: 60 m / min Y-axis: 60 m / min Z-axis: 30 m / min C-axis: 90 ° sec A-axis: 90 ° sec Total weight approx.20,000 kg Base frame approx.12,500 kg Portal with Z-axis approx. 6,500 kg machine hours: 46.312 h

Datasheet

Request / Contact

- Valk Machines BV

- Kadijk 6

- 8531XD Lemmer

- Niederlande

-

+31 514562904

-

sales@valkmachines.com

www.valkmachines.com

#2079-067 · Planer-Type Milling M/C - Double Column

MTorres - MGP-51350 TT - - 2003 - Siemens 840D

Technical details

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06190 · Planer-Type Milling M/C - Double Column

HEYLIGENSTAEDT - Heynumill 2700-PF - - 2002/2018 retrofit - Heidenhain TNC 430 M

Technical details

3/5 axes CNC portal milling machine with integrated C-axis and changeable milling heads. The machine had a purchase price of € 1.4 million in 2002. An inspection in the seller's plant under power is possible after previous appointment. Condition: The machine was overhauled in 2018, costs of over € 100.000,-. - Drives of the X-axis renewed - New hydraulic power unit - Complete electrical wiring renewed - Spindle cooling unit new - 2 pieces longitudinal conveyors new - Coolant pump new - Cover complete X-axis new - Bellows Y-axis new - Exchange measuring ruler X-axis - Fork head spindle bearing new Belleville spring assembly new Drive motor A-axis new Spindle cone ground - Overhaul milling gear (2020) Working range Travels X-axis 3000 mm Y-axis 4000 mm Z-axis 1500 mm Max. column passage 2700 mm Max. Distance between work table and spindle nose: Lower edge of ram interface min./max. 660 mm / 2160 mm Workpiece table Length 3000 mm Width 2000 mm Load 4 t/m² T-slots 28 H8 Rapid traverse X-axis 15000 mm/min Y-axis 15000 mm/min Z-axis 15000 mm/min Equipment: CNC control Heidenhain TNC 430 M Milling heads: Straight milling head type FK 120/450 Outside diameter 280 mm Tool holder SK 50 power max. 67 kW max. speed 5000 rpm Coolant supply through the spindle, via adjustable nozzles 1-axis fork-type milling head type FK 100/2D tool holder SK50 power max. 67 kW max. speed 4000 rpm swiveling range A/B axis +105°/-95° Coolant supply via adjustable nozzles Coolant tank 1.000 l Chip conveyor system Change head station Weight specifications: 1 Y-slide 7000 kg 2 ram 10000 kg 3 column 1 8000 kg 4 column 2 8000 kg 5 crossrail 28000 kg 6 Bed/table 20000 kg 7 Hydraulic power unit 1000 kg 8 Cooling unit 1200 kg 9 Coolant tank ??? Total 83200 kg

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-739597 · Planer-Type Milling M/C - Double Column

WALDRICH COBURG - MULTITEC 2500 AP - - 2002 - SIEMENS 840 D

Technical details

Technical description : Planer Type Milling Center with tool changing system and one second table plate.

Datasheet

Request / Contact

- desba TRADING

- Im Hofgarten 6

- 61130 Nidderau

- Deutschland

-

+49 (0)6187 20 30 749

-

info@desba-trading.de

www.desba-trading.de

#2072-2053 · Planer-Type Milling M/C - Double Column

HANDTMANN - NT 300 / 220 T - - 2001 - Fidia C20

Technical details

• Traverse paths: X axis approx. 4,200mm, Y axis approx. 2,750mm, Z axis approx 1,650mm, °C axis approx. +/-275° and A axis +95° / -120° • Fixture space: approx. 3,000mm x approx. 2,200mm x approx. 980mm • Table size: 3,000mm x 2,200mm with T-slots in a 150mm grid • Table load: 1,000kg / m² table surface • Working and rapid traverse speed: max. 20m/min • Machine dimensions: length approx. 9,500mm (without housing), width approx. 5,900mm, height approx. 6,400mm (Z axis extended) • Weight: approx. 40,000kg • Controller: Fidia C20 • Spindle: HSK 63 from Fischer (Switzerland), 24,000 rpm (grease lubricated) • Spindle hours: 6,939 hours (as of 05/16/22) • Total hours: 76,793 hours (as of 05/16/22) • Tool changer: 2 tool magazines with 30 tool places each, max. Tool weight 4kg, max. tool diameter 80mm or Ø125mm if no two sister tool places, max. tool length 280mm cover plate pneumatic • Cooling: tool spray device with a container of 19.5 l, spray head with adjustable output 0.04 - max. 2.3l/h • Tool control: Blum Laser • Wireless probe: Manufacturer M&H, type 25.10, year of manufacture 2021 • Exchange ball screw X - axis 10.07.2018. • Telescope cover replaced on February 26, 2019 on one side.

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S1901 · Planer-Type Milling M/C - Double Column

WALDRICH-COBURG - MULTITEC 2500 AP - - 2001 - Siemens Sinumerik 840 D

Technical details

Universal portal milling machine Pallet system: 2-fold traverse paths Pallet carrier longitudinal (X-axis): 4000mm Milling and drilling unit horizontal (Y-axis): 3500mm Spindle slide vertical (Z-axis): 1500mm Transom vertical (W axis): 1500mm Passage width between stands: 2500mm Headroom between pallet and spindle nose: 2500mm adjustment speeds X,Y,Z axis: 0 - 60000 mm/min W axis: 0 - 6000 mm/min Milling and drilling unit: M4 Drive power: 45kW Speed ??range of the milling and drilling spindle 1st stage: 5-1300 rpm 2nd stage: 23-6000 rpm Rated speed: 330 min-1 Max.torque: 1250Nm Cross-section of the spindle slide: 400 x 400 mm pallet system Number of pallets: 3 Clamping dimensions of the pallets: 2000 x 3000mm T-slots converted: 28mm H8 Maximum workpiece weight: 10000kg Pallets are changed: manually using an indoor crane Number of setup stations: 3 main dimension Passage width b between the uprights: 2500mm Passage height h between pallet and spindle nose: 2500mm Total length L of the machine (without pallet system): approx. 10000mm Total width B of the machine (without pallet system): approx. 9770mm Total height H of the machine above ground: approx. 6650mm Accessories and Options - Renishaw probe - Automatic changing system for tools and processing units manipulation - Double gripper for changing tools in the machining units - Double gripper for changing processing units in de milling and drilling unit - Tool weight max. 50kg - Tool collar diameter 97.5 - 125mm - max. weight for processing units 750kg shelf magazine - 4 shelves - 192 stations for tools - 4 stations for machining units - Tool holder ISO 50A according to DIN 69871 - Distance from station to station 140mm - max. tool diameter with occupancy of each station 135mm - max. standard tool diameter 250mm / with direct feed via shuttle 315mm / max. tool length standard: 400mm / when stored in the top row of shelves (16 stations in the shelf): 600 mm - Follow-up care - Main time parallel storage and retrieval or inspiration from Tools and processing units - Loading station with PC for entering, editing and managing tool data - Electrical equipment including motors and connection cables - Protective grille with automatic door to the working area - Operating instructions / documentation - Machine parameters on storage medium

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03295 · Planer-Type Milling M/C - Double Column

FOREST-LINE - Minumac II S 35 TH/AC - - 2000 - Siemens

Technical details

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-741 · Planer-Type Milling M/C - Double Column

AWEA - VP 2012 - - 1998 - SIEMENS 810D

Technical details

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-739559 · Planer-Type Milling M/C - Double Column

WALDRICH SIEGEN - POWERTEC 4000 AP - - 1995 - SIEMENS 840 C

Technical details

Technical description : PLANER TYPE MACHINING CENTER – EACH WITH 3 PALLETS 9000 x 3000 mm: - Tool changer with 420 tools - Head pick-up system - Video monitoring via camera - High pressure lubrication unit for inner cooling 70bar AVAILABLE HEAD UNITS: - Fixed angle head HS800C600 105 Kw 600 long - Fixed angle head HSD350C850 50 Kw 850 long - Fixed angle head HSD 40C880 12 Kw 880 long - Fixed angle head HSD 190C1000 30 Kw 1000 long - Vertical spindle unit VS800C 105 Kw 900 long - Universal spindle unit USIO40C 20 Kw B-axis rotatable at 1° at a time - Angle spindle unit SO800C905 - 22,5° fix - Angle spindle unit HSE1200CS -25° fix - Universal spindle unit (fork milling) USP475C 75 Kw 1/2° Hirth One additional drilling extension SE 350C plus 1 SE500C. Description of condition : In 2011/2012 these 2 identical machines were retrofitted and rebuilt by WALDRICH COBURG. The milling length was extended to 14meters and an automatic changing system for table pallets was installed. Both machines can be seen under power by prior appointment. VIDEO: https://youtu.be/1QQV0A5vzf0

Datasheet

Request / Contact

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

#2034-29 · Planer-Type Milling M/C - Double Column

WALDRICH-COBURG - POWERTEC 4000 AP - - 1995 - SIEMENS 840C

Technical details

ATTACHMENTS angular milling head yes autom. tool clamping yes ball spindles yes guideway covers yes coolant unit yes high pressure cooling syst. (through spindle) yes closed cabin yes chip conveyor yes TECHNICAL DESCRIPTION PLANER TYPE MACHINING CENTER - EACH WITH 3 PALLETS 9000 x 3000 mm: - Tool changer with 420 tools - Head pick-up system - Video monitoring via camera - High pressure lubrication unit for inner cooling 70bar AVAILABLE HEAD UNITS: - Fixed angle head HS800C600 105 Kw 600 long - Fixed angle head HSD350C850 50 Kw 850 long - Fixed angle head HSD 40C880 12 Kw 880 long - Fixed angle head HSD 190C1000 30 Kw 1000 long - Vertical spindle unit VS800C 105 Kw 900 long - Universal spindle unit USIO40C 20 Kw B-axis rotatable at 1° at a time - Angle spindle unit SO800C905 - 22,5° fix - Angle spindle unit HSE1200CS -25° fix - Universal spindle unit (fork milling) USP475C 75 Kw 1/2° Hirth One additional drilling extension SE 350C plus 1 SE500C. DESCRIPTION OF CONDITION In 2011/2012 these 2 identical machines were retrofitted The milling length was extended to 14meters and an automatic changing system for table pallets was installed. Both machines can be seen under power by prior appointment.

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-740868 · Planer-Type Milling M/C - Double Column

WALDRICH COBURG - POWERTEC 4000 AP - - 1995 - SIEMENS 840 C

Technical details

Technical description : PLANER TYPE MACHINING CENTER WITH 2 PALLETS 9000 x 3000 mm: - Tool changer with 420 tools - Head pick-up system - Video monitoring via camera - High pressure lubrication unit for inner cooling 70bar AVAILABLE HEADUNITS: - Fixed angle head HS800C600 105 kW 600 long - Fixed angle head HSD350C850 50 kW 850 long - Fixed angle head HSD 40C880 12 kW 880 long - Fixed angle head HSD 190C1000 30 kW 1000 long - Vertical spindle unit VS800C 105 kW 900 long - Universal spindle unit USIO40C 20 kW B-axis rotatable at 1° at a time - Angle spindle unit SO800C905 - 22,5° fix - Angle spindle unit HSE1200CS -25° fix - Universal spindle unit (fork milling) USP475C 75 kW 1/2° Hirth One additional drilling extension SE 350C plus 1 SE500C. Description of condition : both identical machines are retrofitted by WALDRICH COBURG in 2011. The x travel was extended to totally 14.000 mm. A pallet changing system was installed. Both machines are under power and can be inspected by appointment. VIDEO: https://youtu.be/1QQV0A5vzf0

Datasheet

Request / Contact

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9137 · Planer-Type Milling M/C - Double Column

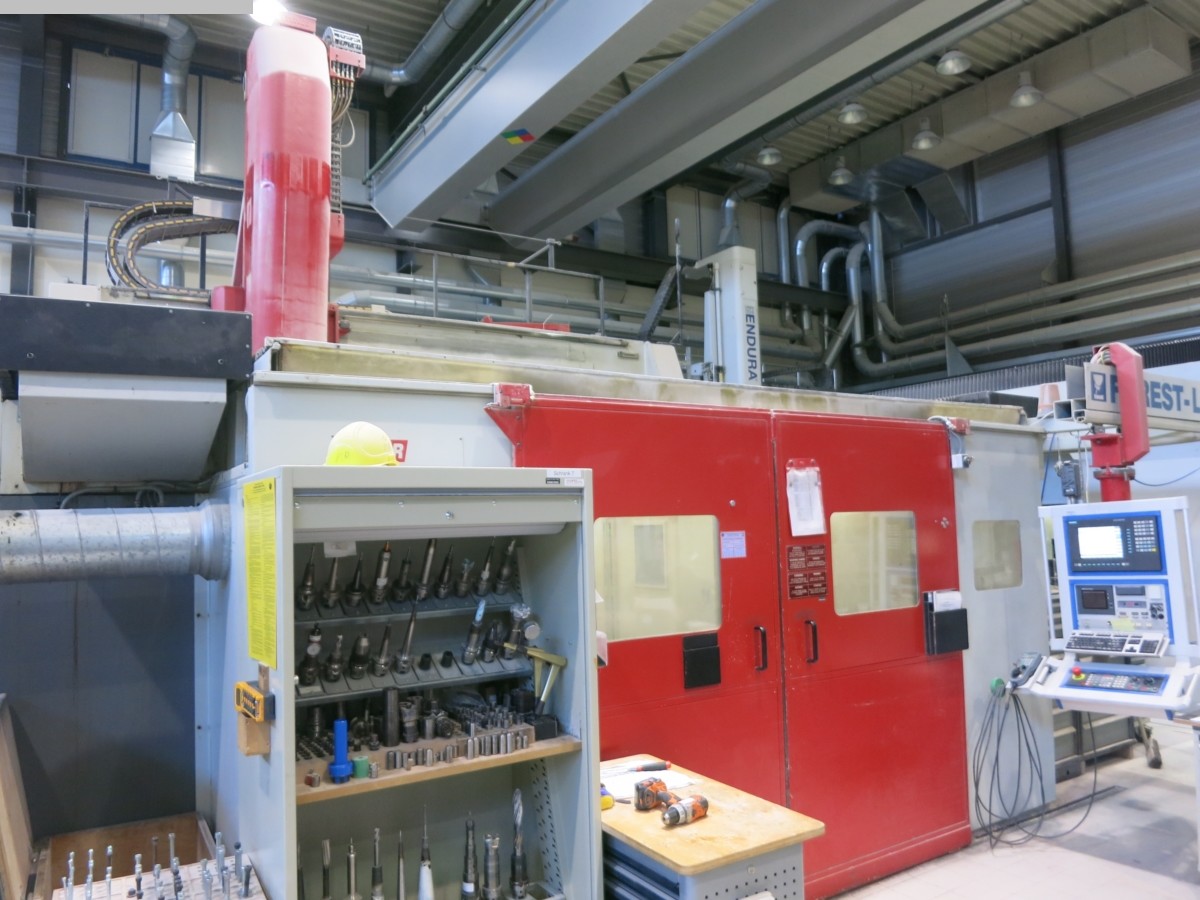

FOOKE - Endura 8 LB300/41/12/5-20 - - 1995 - 840 D SL Operate Siemens

Technical details

5 Axis - CNC - Double Column Travelling Milling Machine FOOKE - Endura 8 LB300/41/12/5-20 - including clamping device and housing

TOP Manufacturer:

CORREA - WALDRICH-COBURG - KRAFT - WALDRICH COBURG - WALDRICH-SIEGEN - KRAFT/SKYMASTER - V-TEC - MAZAK - AWEA - CNC - DROOP & REIN -