Sheet metal working - shaeres - bending

Machinelist: Sheet metal working / shaeres / bending

Plate Bending Machine - 3 Rolls

- Kurt Steiger Werkzeugmaschinen GmbH

- Flachstr. 11

- 65197 Wiesbaden

- Deutschland

-

+49 (0) 611/421047

+49 (0) 611/421040 -

info@kurt-steiger.de

www.kurt-steiger.de

#2043-19334 · Plate Bending Machine - 3 Rolls

AKYAPAK - 1030 x 70 - - 1998 -

Technical details

working width: 1050 mm

metal sheet thickness: 1,5 mm

upper roller-Ø: 70 mm

below roller-Ø: 70 mm

Njw93ychg

weight: 320 kg

space needed: 700 x 1300 x 1100 mm

Plate Bending Machine - 4 Rolls

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E05155 · Plate Bending Machine - 4 Rolls

AKYAPAK - AHS 30/86 - - Neu / New -

Technical details

4 Rolls Hydraulic Bending Machine Standard Features: - hardened and polished rolls - complete body made of ST-52 steel - hydraulic powered cover for easy material extracting - 2-axis digital readout for side rolls - top and bottom rolls are driven by hydraulic and gearbox. Bottom rolls vertical movements are hydraulic powered - separate control panel - oil cooler - conic bending - in accordance to CE-norm Optional Accessories: - variable speed of rotation (10.187 Euro) - material feeding table 1000 x 2000 (5.600 Euro) - center support (33.250 Euro) - 2 x side supports (29.000 Euro)

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E05862 · Plate Bending Machine - 4 Rolls

AKYAPAK - AHS 30/32 - - Neu / New -

Technical details

4 Rolls Hydraulic Bending Machine Standard Features: - hardened and polished rolls - complete body made of ST-52 steel - hydraulically opened/closed drop end controlled from control panel - digital readout for side rolls - top and bottom rolls are driven by hydraulic and gearbox. Bottom rolls vertical movements are hydraulic powered - separate control panel - oil cooler - conic bending - in accordance to CE-norm - Warranty 12 months Optional Accessories: - variable speed of rotation (5.858,00 Euro) - material feeding table (5.100,00 Euro) - center support (18.750,00 Euro) - 2 x side supports (15.000,00 Euro)

Plate Bending Machine - 4 Rolls

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08500 · Plate Bending Machine - 4 Rolls

AKYAPAK - AHS 30/40 - - NEU / NEW -

Technical details

4-ROLL Hydraulic Plate Rolling Machine Working length 3100 mm Maximum thickness Pre-bending 40 mm Bending 50 mm Yield Point: 240 N/mm2 Number of rolls 4 Motor Power 55 kW Min. diameter mm - Ø Top Roll Diameter x 3 Top roll Ø 540 mm Bottom roll Ø 510 mm Side roll Ø 440 mm Length 6700 mm Height 3000 mm Width 3000 mm Weight 40.000 kg With: Cone bending device Induction hardened rolls Digital readout for side rolls Fully welded steel (St-52) frame Separate moveable control panel Dual bending speeds Electronic Parallelism All rolls are mounted in spherical roller bearings Hydraulically opened/closed drop end controlled from control panel Activation of cone rolling function and position adjustment via buttons on the control panel Central rolls (top and bottom rolls) driven by hydraulic motors and planetary gear reducers Electro – hydraulic calibration OPTIONAL FEATURES AND ACCESSORIES: Unit Qty Price (€) Variable speed of rotation: 6.600,- € Material feeding table: 5.100,- € Center support: 18.750,- € Side supports (left and right): 15.150,- € GENERAL CONDITIONS: WARRANTY 12 Months. The warranty expires in case of incorrect utilization and requires using original Akyapak spare parts and consumables. The warranty period starts after installation and commissioning of the equipment. INCOTERMS Exworks, Bursa, Turkey PAYMENT Via cable money transfer 30% downpayment with the placement of order. 70% balance upon notice of goods ready for shipment INSTALLATION, COMISSIONING AND TRAINING Installation, commissioning and training requested by a customer is provided by Akyapak for an extra fee. All required items such as lubricants, oil, air compressor, items for connections of hydraulic, electric and air, test materials to be used during training and all other possible requirements are subject to be provided by the purchaser. OFFER VALIDITY 30 days.

- Bästlein

- Augsburger Str. 56

- 89312 Günzburg

- Deutschland

-

+49 (0) 8221 93037-0

+49 (0) 8221 93037-29 -

info@baestlein.com

www.baestlein.com

#1123-4040368 · Plate Bending Machine - 4 Rolls

AKYAPAK - AHS 25/10 - - 2019 - CNC

Technical details

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-W239 · Plate Bending Machine - 4 Rolls

Roundo - PAS-460 x 4200 - - 1978 -

Technical details

Driven roles: 2 Hydraulic folding bearings Hydraulic pre-bending Main engine power: 55 kW Delivery capacity: 4200 x 14 - 18 mm Roller cap. at diam. > 1,500 mm: 4,200 x 21 - 26 mm Roller cap. at diam. > 2.500 mm: 4200 x 25 - 31 mm Roller cap. at diam. > 3,500 mm: 4,200 x 27 - 33 mm Roll speed: max. 7 m./min. Max bending force lower roll: 400 Ton Max bending force per side roll: 200 Ton With digital reading

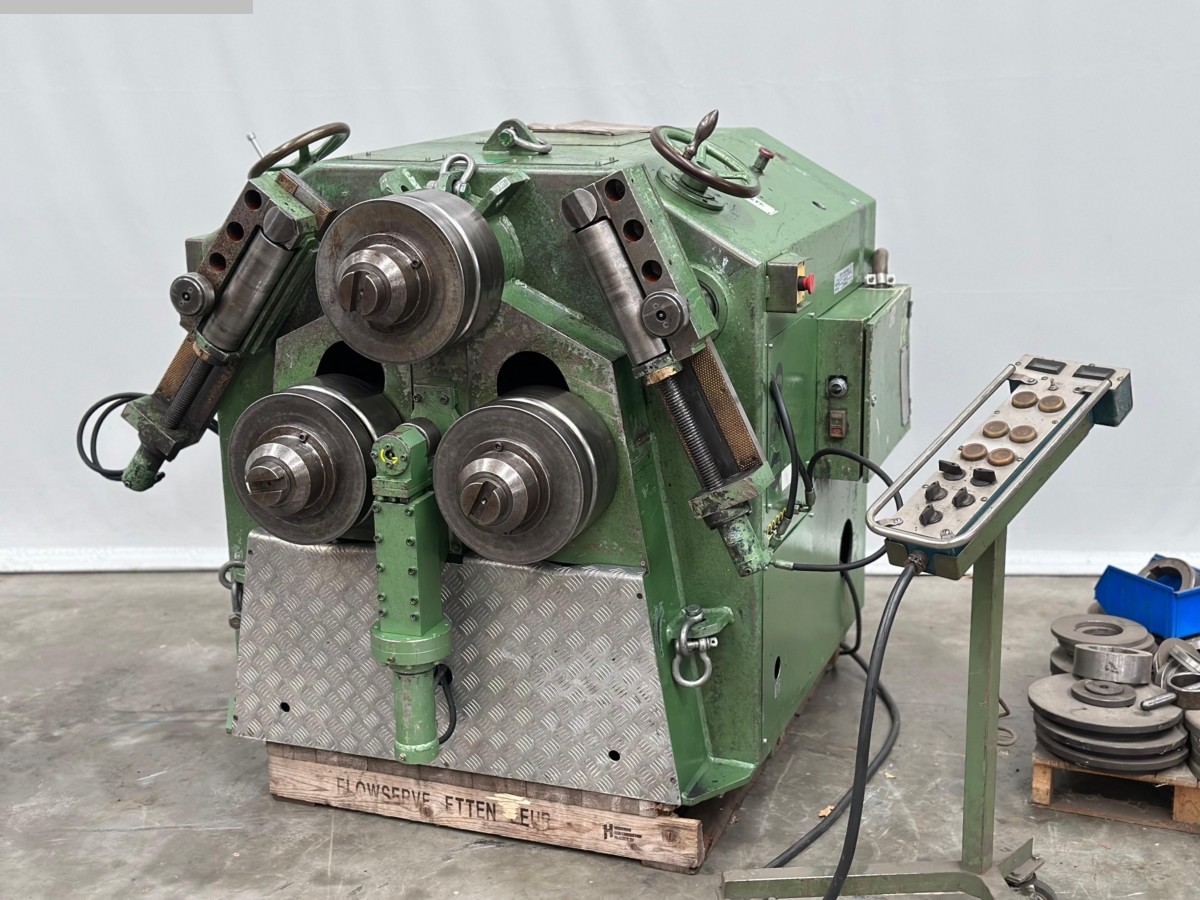

Profile-Bending Machine

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PR112 · Profile-Bending Machine

Roundo - R-4-S - - 1994 -

Technical details

Marke Roundo Maschinen-Nr PR112 Typ R-4-S Baujahr 1994 Durchmesser Abtriebswelle 105 mm ø Maschinenabmessungen (L×B×H) 1.600 x 1.400 x 1.400 mm Maschinengewicht 3.000 kg Kapazität siehe Tabelle. 3 Rollen hydraulisch angetrieben. Inklusive verschiedener Rollen.

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PR113 · Profile-Bending Machine

Roundo - R-2 - - 1993 -

Technical details

Brand Roundo Machine no PR113 Type R-2 Year of make 1993 Output shaft diameter 65 mm ø Machine dimensions (L×W×H) 1.050 x 900 x 1.150 mm Capacity: 7 cm3 3 rollers hydraulic driven Hydraulic adjustment of the 2 bending rollers. Digital reading of the 2 bending rollers.

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PR081 · Profile-Bending Machine

Roundo - R-5-S - - 1991 -

Technical details

With set of standard rolls For additional information, please refer to the pdf file

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PR088 · Profile-Bending Machine

Roundo - RP-5 - - 1987 -

Technical details

Rolls bending machine - 3 Rolls

- Frech GmbH

- Werderstr. 82

- 74889 Sinsheim

- Deutschland

-

0049-7261-1011

0049-7261-63966 -

info@frech-maschinen.de

www.frech-maschinen.de

#1073-55705 · Rolls bending machine - 3 Rolls

ROUNDO - PP 195 - - 1984 -

Technical details

Top roller diameter: 195 mm Includes rollers for rolling flat steel Clockwise and anti-clockwise rotation via handheld control unit

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-w261A · Rolls bending machine - 3 Rolls

Roundo - PA 205 - - -

Technical details

Brand Roundo Machine no W261 Type PA 205 Machine dimensions (L×W×H) 3.100 x 900 x 1.750 mm Machine weight 3.200 kg Hydraulic Roll length 2.000 mm Plate thickness 8 mm Number of rolls 3 Diam. top roll 200 mm ø Powered Rollers 2 Hydraulic Flap Bearing Hydraulic bending 2 rollers hydraulic driven.

Section Bender

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7089 · Section Bender

AKYAPAK - APK 45 - - NEU -

Technical details

- higher speed 6.6m/min - l-steel flat 80x15 (d600)mm - l-steel on edge 60x10 (d800) mm - Angle steel 45x5 (d600) mm - Solid material Ø 35.0 (d700) mm - Pipe diameter max. 60x2.0 (d1000) mm - Square material 45x45x3.0 mm

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2360009 · Section Bender

AKYAPAK - APK 61 - - NEU -

Technical details

- hydraulic roller drive - Planetary gear delivery of the 2 lower rollers - for extra small bending radii - hardened tool holder (42CrMo4) - Standard roller set, hardened - lateral straightening rollers - mobile control panel - 3 powered rollers - Digital display - Machine can be used horizontally and vertically - CE mark / declaration of conformity - User manual in German

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2360008 · Section Bender

AKYAPAK - APK 81 - - NEU -

Technical details

Furnishing: - hydraulic roller drive - Planetary gear delivery of the 2 lower rollers - for extra small bending radii - hardened tool holder (42CrMo4) - Standard roller set, hardened - Hydraulically adjustable side straightening rollers - mobile control panel - 3 powered rollers - Digital display - Machine can be used horizontally and vertically - CE mark / declaration of conformity - User manual in German Special accessories included in the price: - hydraulic side roller adjustment

- Feyen Maschinen GmbH

- Gelleperstr. 10

- 47809 Krefeld

- Deutschland

-

0049 (0)2151/5267-0

0049 (0)2151/5267-39 -

info@feyen.de

www.feyen.de

#1053-003404 · Section Bender

AKYAPAK - APK 30 - - 2007 -

Technical details

Equipment: • Base frame of the machine • Foot switch • Standard-rolls (divided)

Sheet metal working machines are machines used in the metalworking process involved in the production of sheet metal. Some of the types of used sheet metal working machines involved in this process are lathes roll slitters brake presses and stamping presses to name just a few. These used sheet metal working machines are used to cut bend flatten and otherwise manipulate metal into the desired shape and thickness. Used sheet metal working machines can be used to roll or bend sheet metal into a desired shape and to give the fold or curve the desired angle they can also be used to punch the sheet metal into the desired shape.

Used sheet metal working machines for every applicationFrom small home production labs for hobbyists to large-scale production facilities LagerMaschinen.de has used sheet metal working machines for every use. For some precision is not necessarily the most important consideration when choosing used sheet metal working machines. For others the precision and the flexibility of the used sheet metal working machines is the most important consideration. Whether you need bending folding cutting pressing or punching machines you will find what you are looking for at LagerMaschinen.de

Quality used machines at LagerMaschinen.deFor many companies the cost of new equipment can be a source of problems. With its international network of suppliers LagerMaschinen.de ensures that your used sheet metal working machines meet your quality requirements and at the same time guarantees a price that is far more cost-effective than new machines.

TOP Manufacturer:

OSTAS - TRUMPF - HESSE BY DURMA - ERMAK - DURMA - FASTI - NN - EHT - ASSISTMACH - GEKA -