Search:

- Main-Categories

- Categories

- > Metal Processing

- Grinding machines

- Double Wheel Grinding Machine [1]

- Double Wheel Grinding Machine - vertic. [2]

- Face Grinding Machine [2]

- Saws

- Band Saw [6]

- Band Saw - Automatic [4]

- Band Saw - Automatic - Horizontal [2]

- Bandsaw - Horizontal [1]

- Makes

- [348]

- AYEL-TECH [1]

- Brandt Motor Producten NV [1]

- DMG DECKEL-MAHO [1]

- GILDEMEISTER DMG [2]

- UNBEKANNT [1]

- YANG EAGLE [2]

- (vermutlich) HILMA [2]

- - [4]

- . [6]

- /SANDVIK [1]

- 1 PROFI PRESS [2]

- 100GASPARINI [1]

- 1300MMT-germany [1]

- 1512 [1]

- 1516 [1]

- 1D-PML [1]

- 1DURMAZLAR [1]

- 1KUESTERS,KREFELD [1]

- 1SCHLEICHER/GSW [1]

- 25 [1]

- 295UNBEKANNT [1]

- 2A620-2 [1]

- 2A622-1 [1]

- 2HEIDELBERG [1]

- 2KM [2]

- 3+ EXTRICOM [2]

- 3BERG & SCHMID [1]

- 3HBM [1]

- 3M [1]

- 3M / BSW [1]

- 4-jaw chuck [1]

- 5TAG-EIGENBAU [1]

- 5VDF BOEHRINGER [1]

- 7POREBA [1]

- 95T-NUTEN Aufspannplatt [1]

- ? / Unbekannt [1]

- A + B [6]

- A + B Kippcontainer [3]

- A+B [9]

- A+B ERBEND [2]

- A+B FASTECH [4]

- A+B Kreuztisch [1]

- A.I. [3]

- AARDING [1]

- AB MARWIN [1]

- ABA [11]

- ABA Z&B [1]

- ABA / ZIERSCH & BALTRUSCH [2]

- ABAWERK [1]

- ABB [4]

- ABB + Brueninghaus Hydromatik [1]

- ABB + DENISON [1]

- ABENE [1]

- Abfuhrrollenbahn [1]

- ABH Granlund [1]

- ABK [2]

- Abkantwerkzeugschrank [1]

- ABM [9]

- ABS [1]

- Absauganlage [1]

- Absolent [1]

- ABUS [38]

- AC-MOTOREN [2]

- ACCUWAY [1]

- ACETI [1]

- ACIERA [5]

- ACME [1]

- ACO - Bandschleifer [4]

- ACONA [1]

- ADAM [1]

- ADAMS [1]

- ADAPTER / FLANSCH [1]

- ADAST [3]

- ADDA [1]

- ADIGE [1]

- ADIRA [1]

- ADK [2]

- ADM [1]

- AEG [4]

- AFA [1]

- AFB [1]

- AFC [1]

- Ageha.-Zeatz [1]

- AGEO [2]

- AGFA [2]

- AGIE [8]

- AGIE - CHARMILLES [1]

- AGIE-CHARMILLES [4]

- Agre [1]

- AGRIA [1]

- AGRITEC [1]

- AH E60 [1]

- Ahlmann [1]

- Ai [1]

- AICHELIN [1]

- AIRCRAFT [2]

- AIRLESS [1]

- Airpress [1]

- AJAX [2]

- AJBK [1]

- AK BEND [23]

- AK-BEND [33]

- AKBend [2]

- AKIRA SEIKI [1]

- AKV [1]

- AKYAPAK [14]

- AL-KO [3]

- ALBA [1]

- ALBANY [14]

- Albright [1]

- ALFRA [1]

- ALIA JUNIOR TAP [1]

- ALIKO [1]

- ALKETT [1]

- ALKO [2]

- ALLEN [2]

- Allhydro [1]

- ALLIED MACHINE & ENGINEERING [1]

- Allis - Chalmers [1]

- ALLMATIC [8]

- ALLOG [1]

- ALLWEILER [1]

- ALME GERIMA [1]

- ALMI [12]

- ALPA [2]

- ALPEN [1]

- ALPEN SUPER [1]

- ALPHA TECHNOLOGIES [4]

- ALPHATEC [10]

- ALTEC [1]

- ALTENDORF [2]

- Aluminiumbleche [1]

- ALUP [3]

- ALVITAR [1]

- ALZMETALL [83]

- AMADA [33]

- AMADA PROMECAM [3]

- AMBOLD [11]

- Amec [2]

- AMERESCO [1]

- AMF [4]

- AMGA [2]

- AMINO [1]

- AMK [1]

- AMPAG - KöLN [1]

- AMT [3]

- AMUT [2]

- ANATRONIC [1]

- Anayak [14]

- ANGER [1]

- ANREISSPLATTE [1]

- Ansaldo San Giorgio [1]

- ANTEK [1]

- Anzugsbolzen [1]

- AP&T [1]

- APE Engineering [1]

- Apollo [3]

- Arbeitskorb [1]

- ARBOGA [4]

- ARBURG [12]

- ARCO [1]

- ARGUS - FLOWSERVE [1]

- Aria Pulita Impianti [1]

- ARIX [1]

- ARKU [8]

- ARMANN [1]

- ARMO [1]

- ARNO [4]

- ARNOLD [3]

- ARNOLD SHINJO [1]

- Arnold Tech GmbH [1]

- ARNTZ [4]

- ARO [1]

- AROWA [5]

- ARP [1]

- ARTHUR KLINK [1]

- Artmann Hamburg [1]

- ASCHERSLEBEN [4]

- ASCHERSLEBEN-SCHIESS [1]

- ASDORF [2]

- ASECOS [1]

- Asquith [2]

- ASSERVIMENTI [1]

- ASSFALG [1]

- Assistmach [10]

- ATA [1]

- ATB [1]

- ATB LOHER [1]

- ATLANTA [3]

- ATLANTIC [16]

- ATLANTIC / HACO [1]

- ATLAS [2]

- ATLAS COPCO [2]

- ATLAS-COPCO [2]

- ATLET [1]

- ATORN [2]

- ATR 400 [1]

- ATW [2]

- AUDAX [1]

- AUERBACH [5]

- AUERBACH & SCHEIBE [1]

- AUFSATZRAHMEN [1]

- AUFSPANNPLATTE [63]

- Aufspannscheibe [1]

- AUFSPANNTISCH [2]

- AUFSPANNWINKEL [4]

- AUSTEN [1]

- Autoblok [2]

- Automatik [1]

- AUTOWELL [4]

- AUTZ+HERRMANN [1]

- AVIA [8]

- AVIA / MEXPOL [1]

- AVL [2]

- AVM ANGELINI [1]

- AVYAC [4]

- AW Maschinen- & Anlagentechnik [1]

- AWEA [4]

- AWEA - CNC [2]

- AWI [2]

- AWL [1]

- AXA [12]

- AXON LITZ [1]

- AYEL-TECH [2]

- AYEN [1]

- B + H [1]

- Babatz [1]

- Bach Apolda [1]

- BACHER [4]

- BAD SALZUNGEN [5]

- BAHMÜLLER [2]

- BAIER [4]

- Bakker [3]

- BAKKER MAGNETICS [1]

- BALCONI [1]

- BALLUFF [13]

- BALZAT [2]

- BANDERA [2]

- BANNING [4]

- Banning Dango & Dango. Andritz [1]

- BARBER COLMAN [1]

- BARON MAX [1]

- BASIS leeg [1]

- BASTON [1]

- Batliboi [2]

- Battenfeld [1]

- BATTENFELD [6]

- BAUBLYS [1]

- BAUER [4]

- BAUER - Südlohn [1]

- BAUER SÜDLOHN [1]

- Bauerle [1]

- BAUHAMMER [1]

- BAUMANN [2]

- BAUMUELLER [3]

- BAUMUELLER NUERNBERG [1]

- Baumuller [1]

- BAUMÜLLER [1]

- BAVARIA [1]

- BAYER [1]

- BAYKAL [23]

- BBC [3]

- BBC / ABB [2]

- BBC BROWN BOVERI [1]

- BBM [1]

- BBT [1]

- BD BECTON DICKINSON [1]

- BDS [1]

- BE-COOL [2]

- BEBA [1]

- BECHE [2]

- BECHLER [1]

- BECKER & VAN HUELLEN [1]

- BEDA [1]

- Behr [1]

- Behringer [17]

- BEHRINGER - Halbautomat [1]

- BEHRINGER EISELE [1]

- BEIL [2]

- BEISSBRATH [1]

- BEKA-MAK [4]

- BELLAFORM / KUHNE [1]

- BELLHEIMER [2]

- BEMA [2]

- BEMA, LUISAGO, ITAL. [1]

- BEMATO [4]

- BENDMAK [2]

- BENZ [1]

- BENZINGER [2]

- BERCO [1]

- BERG [1]

- BERG & SCHMID [84]

- BERG & SCHMID - Halbautomat [1]

- BERG & SCHMID - Vollautomat [1]

- BERG & SCHMID VOLLAUTOMAT [1]

- Berg (ibag) [1]

- BERG SCHMID - Halbautomat [1]

- BERGER [1]

- Berger Lahr [1]

- BERGMANN [1]

- BERGONZI [1]

- BERKO [1]

- BERNADO [1]

- BERNARDO [85]

- Bernstein [2]

- BERRENBERG [4]

- BERRIOLA / YASKAWA [1]

- BERSTORFF [3]

- BERTHIEZ [5]

- BETOL [2]

- BETZ [2]

- BEUMER [1]

- BEUTLER [8]

- BEWO [9]

- BEYELER [9]

- BEYER [4]

- BGU [2]

- BHTOY [1]

- BIANCO [16]

- BICKEL [2]

- BIEGEMASTER [23]

- Bielsa [1]

- BIGLIA [6]

- BIGSTONE - Vollautomat [1]

- Bihl+WIEDEMANN [2]

- Bihler [2]

- Bijlsma [1]

- Billaud [1]

- BILZ [1]

- Bimak [2]

- BIMT [1]

- BINNS & BERRY [2]

- BISON [2]

- BIZERBA [2]

- Black Steel [4]

- BLANCHARD [2]

- BLANSKO [3]

- BLASER [1]

- BLE [1]

- BLEMA-GOTHA [1]

- BLEMAS [1]

- Blies-Bret [1]

- BLOHM [14]

- Blue Laser Tools [1]

- BLUME & REDECKER [1]

- BLUTHARDT [3]

- BLUTHARDT/PARABO [1]

- BMF [3]

- BMS [1]

- BMSY [3]

- BMT [2]

- Bode [2]

- BOECKER [1]

- BOEHLER [1]

- BOEHRINGER [14]

- Boehringer VDF [1]

- BOELLHOFF [1]

- BOENI [1]

- BOETTCHER & BRUECKMANN [1]

- BOGE [6]

- BOGE - MATTEI - BEKO [1]

- BOGE Solidbase [1]

- BOHLE [5]

- BOHNER & KOEHLE (BOKOE) [1]

- BOHNER & KÖHLE [4]

- BOHRPOWER [1]

- Bohrstangen [1]

- BOKÖ [3]

- BoKö / BOHNER & KÖHLE [1]

- Boldrini [1]

- BOLEY [4]

- Bollhoff [1]

- BOMAR [4]

- BOMAR - Vollautomat [1]

- BONNHOFF [4]

- BOREL [1]

- BORMASTER [1]

- Bornemann [1]

- BORRIES [1]

- BOSCH [31]

- BOSCH Rexroth [180]

- BOSCHERT [16]

- Bosi Vittorio [1]

- BOSS [1]

- BOTEK [10]

- BOURG [1]

- BOY [1]

- BRAGONZI [1]

- Bramidan [1]

- Brammax [1]

- Brammen [1]

- BRANSON [1]

- BREBOMA [1]

- BREDA [3]

- BRET [1]

- BREUNING IRCO [4]

- BREUNING-IRCO [1]

- Brevete [1]

- BRIDGEPORT [9]

- Bridgeport ( Bauart ) [1]

- BRIERLEY [1]

- BRINKMANN [2]

- British Federal [1]

- Bronswerk [2]

- BRONX [2]

- BROOK HANSEN [1]

- BROOK HANSEN + DENISON [1]

- BROOK HANSEN + VICKERS [1]

- Brother [7]

- Brown [1]

- BROWN & SHARP [1]

- Brown Duncan & Co [1]

- BRUCKNER [5]

- BRUDERER [11]

- BRYANT [1]

- BRÜCK [1]

- BSM [1]

- BT [1]

- BTEV-KLEMOTA [1]

- bticino [1]

- BTM - VOLLAUTOMAT [1]

- BUCK [1]

- BUDERUS [1]

- BUECHE [1]

- Bueltmann [1]

- BULGARIEN [1]

- BULLARD [2]

- BULMAK - ZMM SLIVEN [2]

- BURENO [1]

- BURGER [2]

- BURGHARDT & SCHMIDT [2]

- BURGSMUELLER [2]

- BURKA KOSMOS / HOEFLER [1]

- BURKARDT & WEBER [1]

- BURKARDT + WEBER [1]

- Burkhard&Weber [1]

- Burkhardt & Weber [1]

- BURKHARDT + WEBER [2]

- BURNET [1]

- BURSTER [7]

- BUSCH [4]

- BUTLER NEWALL [1]

- BUTLER-ELGAMILL [2]

- BUTLER-NEWALL [4]

- BVL / ROESLER [1]

- BWF [6]

- BÜCHE [1]

- BÜRKLE [1]

- BYSTRONIC [19]

- BÜTFERING [1]

- BÄUERLE [1]

- BÖLLHOFF [2]

- BÖNNHOFF [7]

- C-TEK [3]

- C2 [1]

- CAB [1]

- CAIR COMPANY [4]

- CAMU [4]

- CAMUT [1]

- CANTALUPPI [1]

- CARDINAL [1]

- CARER [1]

- Carif [1]

- CARL STAHL [4]

- CARL ZEISS [1]

- CARMITECH [1]

- CARNAGHI [3]

- CARNAGHI PIETRO [1]

- CARONNO [2]

- CARTACCI [1]

- CASCADE [1]

- CASE [1]

- CASOLIN [2]

- Castel [4]

- CASTOLIN + EUTECTIC [1]

- CAT [4]

- CAVENAGHI & RIDOLFI [2]

- Cazeneuve [10]

- CBI [1]

- CEA [1]

- CEBORA [1]

- Cegielski [2]

- CEKABA [2]

- Celtic [1]

- CENTRAL HYDRAULICS [1]

- Cerso [1]

- Certex [1]

- CERUTI [1]

- Cevisa [1]

- CGM [1]

- CHANNELLETTER [1]

- CHARMILLES [1]

- Chemiepumpenbau Zofingen AG [1]

- CHEVALIER [19]

- CHICAGO PNEUMATIC [1]

- CHIN FONG [2]

- Chinesisches Fabrikat [1]

- CHIRON [32]

- CHRISTEN [2]

- CHURCHILL [1]

- CIDAN [3]

- Cinch Mill [1]

- CINCINATTI [1]

- CINCINNATI [12]

- CINCINNATI MILACRON [1]

- CINCINNATI-MILACRON [1]

- CITIZEN [12]

- CLAAS [1]

- CLARK [3]

- CLARKSON [2]

- Classica [1]

- CLEARING [1]

- CLOOS [2]

- Cluna [1]

- CMA [2]

- CMC [1]

- CME [4]

- CME SAL [1]

- CMU [1]

- CMZ [8]

- CNC-Multitool GmbH [1]

- Coil [1]

- COILTECH [1]

- COLCHESTER [21]

- COLGAR [4]

- COLLET [6]

- COLLET & ENGELHARDT [1]

- COLLET + ENGELHARD [1]

- COLLIN [1]

- Colly [2]

- COLOMBO [2]

- Colortronic [2]

- COLUMBUS [2]

- COMACA [3]

- Comerio Ercole [7]

- COMESSA [1]

- COMETA [2]

- COMEV [2]

- COMMERCY [1]

- CompAir [5]

- COMPEX [1]

- Comu [1]

- CONCEPT Laser [1]

- Conic [1]

- Conter [1]

- CONTRAVES [2]

- CONTUR [6]

- COOL TECHNOLOGY [1]

- CORDIA [2]

- CORDT [1]

- CORMAK [2]

- CORNAC [1]

- CORNO ITALY [1]

- Coromant Capto [1]

- CORREA [28]

- CORREA/ANAYAK [1]

- CorreAnayak [1]

- COSEMA [1]

- COSEN [1]

- COTTA [1]

- COVEMA/SCHWABE [1]

- CRAVEN [1]

- Cree [1]

- CREUSEN [3]

- CRI-DAN [1]

- CROWN [3]

- Cryogenic Systems & Parts [1]

- CSEPEL [5]

- CUGIR-LORENZ [1]

- Cuoghi [1]

- CUTERAL [1]

- CY257A [1]

- Cyclomatic [1]

- D'Andrea [5]

- D-PML [6]

- D.U.P. [1]

- DAEWOO [7]

- DAEWOO DOOSAN [2]

- DAEWOO/DOOSAN [1]

- DAH LIH LIEDER [1]

- DAHLIH [1]

- DAHLIH LIEDER [1]

- DAIKIN [1]

- Daiss + Partner [1]

- DAISS + PARTNER - VOLLAUTOMAT [1]

- DALEX [5]

- DALMASTROJ-Jugoslawien [1]

- DANGO & DIENENTHAL [6]

- DANOBAT [5]

- DANOBAT ESTARTA [1]

- DARLEY [11]

- DASQUA [1]

- Datalogic [1]

- DAVI [3]

- David [1]

- DDR [4]

- De Moor [1]

- DEA [5]

- DEA (Hexagon) [1]

- DEBER [1]

- DEBUS [1]

- DECKEL [124]

- DECKEL / Fibro [1]

- Deckel Maho [30]

- DECKEL MAHO DMG [10]

- DECKEL- MAHO DMG [1]

- DECKEL-MAHO [31]

- DECKEL-MAHO (DMG) [5]

- DECKEL-MAHO DMG [1]

- DECKER [1]

- Deeweld [3]

- DEFUM [4]

- DEGEN [1]

- DEGUSSA-DURFERRIT [1]

- DEHOUST [1]

- DEKUMED [1]

- DELAPENA [1]

- Delphin [1]

- DELTA [1]

- DELTAL [1]

- Deltech [1]

- DEMA [1]

- DEMAG [45]

- DENER [2]

- DENISON [2]

- DEPA [1]

- DEPO [2]

- DERATECH [1]

- DESCH [1]

- DESMA [3]

- DESMONT [1]

- DESTACO [2]

- DEVLIEG [1]

- DEWALT [1]

- DFK [1]

- DGD COOPER TOOLS [1]

- di-soric [2]

- DIAFORM [1]

- DIBO [1]

- DIEFFENBACHER [4]

- DIETER HANSEN [1]

- Dietich [1]

- DIETZ [1]

- DIGEB [1]

- DIGEP [3]

- DIMECO [8]

- DIN 55029-15 [1]

- DINA [2]

- Diosna [1]

- dirinler [2]

- DISA [1]

- DISKUS [5]

- DITTEL [1]

- diverse [4]

- DIVERSE ABA BLOHM ELB Z&B [1]

- DIXI [5]

- DMC [1]

- DMF [5]

- DMG [35]

- DMG (5-ACHSEN) [2]

- DMG / MORI SEIKI [1]

- DMG DECKEL MAHO [3]

- DMG DECKEL MAHO GILDEMEISTER [2]

- DMG DECKEL-MAHO [2]

- DMG GILDEMEISTER [5]

- DMG MORI [19]

- DMG MORI SEIKI [3]

- DMG-DECKEL [1]

- DMG-DECKEL-MAHO [2]

- DMG-GILDEMEISTER [3]

- DMG-MORI [1]

- DMG-MORI SEIKI [1]

- DMTG [3]

- Doall [2]

- DOEBELI [1]

- DOERRIES [4]

- DOERRIES-SCHARMANN [1]

- Donaldson [7]

- DONAU [2]

- DONAU-KNAPP [2]

- DOOSAN [19]

- DOOSAN DAEWOO [13]

- DOOSAN-PUMA [2]

- DORFNERWERK [1]

- DORRIES [1]

- Dr. HOCHSTRATE [2]

- Drabert Sohne [1]

- DREES [2]

- DREHER [15]

- Dreibackenfutter [1]

- DREISTERN [1]

- Drive Systems [1]

- DRO [1]

- DROGEMEYER [2]

- DROOP & REIN [14]

- DSZ [1]

- DUERR [1]

- DUFOUR [1]

- DUGARD [2]

- DUMETA [92]

- DUNKES [28]

- DURAPLAN [1]

- DURMA [63]

- DURMA / METALLKRAFT [3]

- DURMAZLAR [4]

- DURST [1]

- DÜPERTHAL [2]

- DÜRING [1]

- DÜRR [1]

- DÖRRIES [16]

- DÖRRIES SCHARMANN [2]

- DÖRRIES-SCHARMANN [2]

- E. Dold & Söhne KG [1]

- E.Dold & Soehne KG [1]

- EATON [5]

- EBA [1]

- EBERHARD [1]

- EBU [19]

- ECHEA [3]

- ECKARDT [2]

- ECKERT [1]

- ECKOLD [6]

- ECLAIR [1]

- ECLAIR / PASKOWSKY-Schweiz [1]

- ECLAIRE (SCHWEIZ) [1]

- ECO AIR [1]

- ECOAIR [1]

- ECON [1]

- ECRM [1]

- ED. LUETHY [1]

- EDEL [6]

- EDELHOFF [4]

- EDER [1]

- EDMO LIFT [1]

- EDWARDS [1]

- EFEM [1]

- EFFBE / Greb [1]

- EHP [2]

- EHT [42]

- Eichener [1]

- Eichener [1]

- EIGENBAU [12]

- Eigenbau- [1]

- EIGL [1]

- EIMELDINGEN [7]

- Eimelingen [1]

- EINHELL [1]

- EISELE [13]

- EISELE - Halbautomat [5]

- EITEL [4]

- EITEL / MÜLLER WEINGARTEN [1]

- ELB [21]

- ELB / Hahn & Kolb [1]

- ELB HK Orion [1]

- ELB SCHLIFF [1]

- ELBARON [2]

- ELCON [4]

- Electrox [1]

- ELEKTRA [1]

- Elektra Beckum [1]

- Elektra Thailfingen [1]

- ELEKTRA-BECKUM [1]

- Elektrokovina [1]

- Elektromotorenwerk Dessau [1]

- ELEKTROR [2]

- ELEKTROSTATIK/MESSER GRIESHEIM [1]

- Elga [1]

- ELHA [2]

- ELIOG [1]

- ELMAG [3]

- ELMEA [1]

- Elmot Schaefer [1]

- Elsterwerda [1]

- ELTE [1]

- Eltro / Siemens [1]

- Eltrotec [1]

- Eltrotec Sensor [1]

- ELUMATEC [2]

- ELUMATEC Stabbearbeitung [1]

- EMAG [16]

- EMAG KARSTENS [1]

- EMB [2]

- EMC [1]

- EMCO [20]

- EMGR [1]

- EMK [3]

- EMKA Furnierpresse [1]

- EMOD [4]

- Empire [1]

- EMSA [3]

- EMUGE [4]

- Energy Partners Systems [1]

- ENGEL [11]

- ENSHU [1]

- EP [11]

- EP-SYSTEMS [1]

- Eppinger [1]

- EPPLE [2]

- ERBEND [3]

- Ercole [1]

- ERCOLINA [26]

- ERD [1]

- Erdwich [1]

- EREMA [2]

- ERFI ERGOLINE [1]

- ERFI REKORD [1]

- ERFURT [2]

- ERHARDT & LEIMER [1]

- Erich Plank / WMW [1]

- ERICKSON [2]

- ERL [1]

- ERLO [25]

- ERMAFA [2]

- ERMAK [65]

- ERNAULT SOMUA [1]

- ERNAULT TOYODA [1]

- ERNAULT-SOMUA [3]

- ERNST [3]

- ERO-Fuehrungen [3]

- EROGLU [1]

- ESAB [8]

- Escher [1]

- ESS [1]

- ESSETI (Italien) [1]

- EST-TICINO [3]

- ESTA [2]

- Etiketteneindrucker LEOMAT [2]

- EUBAMA [1]

- EUCHNER [2]

- EUMACH [1]

- Euro Mill Maximart [1]

- Euromac [7]

- Europe Shredders [1]

- Eurospark [1]

- EUROTRONIC [1]

- EVR [1]

- evtl. KAISER & KRAFT [1]

- EWAG [2]

- EWE [1]

- EWS [1]

- EWS und WNT [1]

- EX EMKA [1]

- EX-CELL-O [2]

- EXACTA [1]

- EXCELLO [1]

- EXCELLO / Boehringer [1]

- EXNER [13]

- EXPERT [2]

- EXTRUDER - COMPOUNDER [1]

- EXTRUDEX [3]

- EZset GmbH & Co. KG [2]

- F.EE [14]

- F.I.M. [1]

- Fabr UNBEKANNT [7]

- Fabr. UNBEKANNT [7]

- Fabr. UNBEKANNT/NOT KNOWN [2]

- Fabr. unbekannt/unknown [5]

- Fabris [1]

- Fabris Italy [1]

- Fabrius [1]

- FACCIN [5]

- FADAL [4]

- FAESSLER [2]

- Fag [2]

- Fahr, Epping etc [1]

- FALCON [1]

- FALKEN [34]

- Faltex [1]

- FAMAR [2]

- Famas [1]

- FAMUP [4]

- FAN [1]

- FANUC [94]

- FANUC Amplifier [2]

- FANUC ROBODRILL [1]

- FANUC-STAMA [3]

- FARINA [11]

- Farman [1]

- FARO [4]

- FARREL [1]

- FAS [1]

- Fastbind [1]

- FASTECH [3]

- Fastenrath [1]

- FASTI [56]

- FAT [3]

- FAVRETTO [4]

- FDB [1]

- FDF [1]

- FDF Fritz Duesseldorf Freiburg [1]

- FECKER [2]

- FEE [1]

- FEELER [4]

- FEHLMANN [11]

- FEIN [6]

- FEINMECHANIK DECKEL [1]

- FEINMECHANIK MICHAEL DECKEL [1]

- Feinmesszeugfabrik Suhl [3]

- FEINTOOL [2]

- FEINTOOL-OSTERWALDE [1]

- FEINWERKTECHNIK MARKDORF [1]

- FELDER [1]

- FELDMUEHLE [1]

- Feldpausch [2]

- FELSOMAT [1]

- Femco [1]

- FEMCO-ASTRHAL [1]

- FEMCO1200 [1]

- FEMI [3]

- FENWICK [1]

- FERGUSON [1]

- FERINA [1]

- FERMAT [1]

- FERREL [1]

- FESTO [130]

- FETRA (wahrscheinlich) [1]

- FETTE [18]

- FETTE - PWS - KLINGELNBERG [1]

- FETTE-LMT [1]

- FEXAC [1]

- FEYEN KREFELD [1]

- FEYEN-KREFELD [1]

- FEZER [2]

- FFT [1]

- FI AUTOMAZIONE / ABB [1]

- FIBRO [3]

- FIBRO - Rundtisch [1]

- FIBROTAKT [1]

- FIDIA [1]

- FIL [2]

- FILTOO [1]

- FIM / AMADA [1]

- FIM / INDUMASCH [1]

- FIM/Indumasch [1]

- FIMAL [5]

- FIMI [2]

- FINITURE [3]

- FINKEN [4]

- FINN POWER [1]

- FINTEK [18]

- FIRST [3]

- FISA Manufacturing Srl [1]

- FISCHER [11]

- FIXATOREN [1]

- FKD-FEICHTER [1]

- FLAMEFAST [1]

- Flender [2]

- FLOTT [23]

- FLOW [1]

- FLUIDSYSTEME DASBECK [1]

- Flutec [1]

- FLYGT [4]

- FMB [6]

- FMB / Star [1]

- FMS [3]

- Foellmer [1]

- Fokardt [1]

- Folmer [1]

- FOM [2]

- FOM Industrie [1]

- FOOKE [1]

- Forest Line [2]

- FOREST-LINE [2]

- Forges de Gilly [2]

- FORKARDT [21]

- FORKARDT-SMW [1]

- FORKHARDT [1]

- FORMAT [3]

- FORTE [7]

- FORTEMAT [1]

- Fortuna [2]

- FORTUNA / SKF [1]

- FPT [6]

- FRAMAG [1]

- FRAMATECH [1]

- FRANK [1]

- FRANKO [1]

- Fratelli Giudici [1]

- FRECH [15]

- Frech Espana [1]

- FREI [4]

- FREMTAS [1]

- FRENCO [2]

- Fresmak Arnold [1]

- FREUTEK [1]

- Fricke [1]

- FRIGGI [1]

- Fritsch [1]

- FRITZ HECKERT [1]

- FRITZ MUELLER [1]

- FRITZ WERNER [9]

- FRITZ WERNER BERLIN [1]

- FROEMAG [1]

- FROMMIA [1]

- FRORIEP [13]

- FRORIEP-SCHIESS [1]

- FRÖMAG [8]

- FUHS ELEKTRONIK [1]

- FUJI [1]

- Fukuno Seiki [2]

- FURRER MUELLER [1]

- Futterschutzeinrichtung Drehm. [1]

- FX [1]

- FÄSSLER [1]

- Föratec [1]

- FÖRDERBAND [1]

- G [1]

- G + K [1]

- G.O.S. [1]

- GABRO [1]

- GACO [2]

- GALDABINI [1]

- GAMBIN [2]

- GANNER [1]

- GARANT [11]

- GARANT/HOFFMANN [2]

- GARANT/HOFMANN [1]

- GASPARINI [8]

- Gaussin [2]

- GAUTHIER [1]

- GBF Potvel [1]

- GE FANUC [8]

- Gebr. BAYER [1]

- Gebr. Dickertmann [1]

- GEBR. HAU [1]

- Gebrueder Dickertmann [1]

- GECAM [4]

- GEDEMA [2]

- GEFI GYOER [1]

- GEHRING [9]

- GEIBEL & HOTZ [6]

- GEIBEL + HOTZ [1]

- GEIBEL&HOTZ [1]

- GEKA [46]

- GEKO [1]

- Gelber Bieger [1]

- GEMA [2]

- GEMINIS [9]

- gemischt [1]

- Genie [1]

- GENKINGER [1]

- GEORG [1]

- GEORG FISCHER [4]

- GEORG MÜLLER [1]

- George [7]

- George Fischer [1]

- GER [3]

- GER, Spanien Lizenz ELB [1]

- GERD WOLFF [37]

- GERLACH [3]

- GERLACH Maschinenbau [1]

- GERMA [2]

- GERONNE [1]

- Gerver [2]

- GESSMANN [1]

- GETRA [2]

- Geuma [2]

- GEWEFA [1]

- GHE [1]

- GHIRINGHELLI [1]

- GIANA [1]

- GIDDINGS & LEWIS [3]

- Giddings en Lewis [1]

- GILDEMEISTER [58]

- GILDEMEISTER & KNOLL [2]

- GILDEMEISTER (teilueberholt) [2]

- GILDEMEISTER- DMG [1]

- GILDEMEISTER/gratziano [1]

- GILLARDON [9]

- GIORIA [1]

- GIS [1]

- GISAG [1]

- GLASMACHER [1]

- GLAUCHAU [2]

- GLEASON [10]

- Gleason Fraeskopf [1]

- GLEASON HURTH [4]

- GLEASON PFAUTER [1]

- GLEASON PHOENIX [1]

- GLEASON- PFAUTER [10]

- GLEASON-PFAUTER [4]

- GLEASON-PHOENIX [1]

- Glunz & Jensen [1]

- GMG [1]

- GMN [3]

- GMN (dorries Scharmann) [1]

- GMN Georg Müller [1]

- GMN Georg Müller Nürnberg [1]

- GOEBEL/MSO [1]

- GOETZINGER [3]

- GOLD [1]

- GOLDHOFER [1]

- GOOD AIRE [1]

- GOODWAY [5]

- Goodway GS 2800 M [1]

- GORNATI LEGOOR [1]

- Gorter [3]

- Gosmeta [1]

- GOSSEN [1]

- Goyar [1]

- Gozua [1]

- GRAEBENER [3]

- GRAEBENER multi-station press [1]

- GRAFFENSTADEN [1]

- Granit [1]

- Graphometronic [1]

- GRAUL [1]

- GRAUL-Mühlacker [1]

- GRAULE [7]

- GRAVER GRINDER [1]

- GRAZIANO [1]

- GREENLEE [2]

- GREIF [7]

- GRESSEL [2]

- GRIMME [1]

- GRIT [3]

- GROB [10]

- GROETZINGER [1]

- Gromatic [1]

- GROSS [1]

- GRUNDFOS [3]

- GRUNDIG [1]

- GRUPP [1]

- GRÄBENER [6]

- GRÖTZINGER [1]

- GSP [4]

- GSW [2]

- GSW SCHWABE [10]

- GSW-SCHWABE [2]

- GUALDONI [2]

- GUETHLE-SWT [1]

- GUIFIL [2]

- Guitti [1]

- Gummituch-Schienen [1]

- Gurutzpe [4]

- GUSTAV HESSMERT [1]

- GUSTOS [19]

- Guyson [1]

- GWF [1]

- GWF-MENGELE [1]

- GWK [1]

- GWS [1]

- GÜHRING [36]

- GÜHRING / TITEX [1]

- GÜHRING/VOLZ/TITEX [1]

- Günter Wensing [1]

- GÖCKEL [3]

- GÖTZINGER [11]

- H & H [1]

- HAAG+ZEISSLER [1]

- HAANE [1]

- HAAS [19]

- HABEGGER [1]

- HABERKORN [8]

- HABOR [1]

- HACO [18]

- HAEMMERLE-GF BRUGG [1]

- HAENCHEN [2]

- HAENEL [1]

- Haeuser Vorrichtungsbau [1]

- Haeusler [7]

- HAFFNER [5]

- HAFFNER - Kopierfräse [1]

- HAGEN & GOEBEL [4]

- Haginger [2]

- HAHN & KOLB [9]

- Hahn & Kolb / Hoffmann [1]

- HAHN & KOLB [1]

- Hahn&Kolb [1]

- HAHNDORF [1]

- HAHNDORF (RUWO) [1]

- HAHNDORF - RUWO [1]

- HAIMER [1]

- HAINAN GREAT [1]

- HAIR LIGHT [1]

- HAKO [5]

- Hambi [1]

- HAMM [1]

- HAMMELMANN [1]

- HAN S LASER [2]

- HANAU [1]

- HANDTMANN [2]

- HANG [7]

- HANKOOK [8]

- Hann [1]

- HANNIFIN [1]

- HANS LINDNER [1]

- HANS SCHOEN [2]

- HANS VON DER HEYDE [6]

- HanseLifter [1]

- HANSEN [1]

- Hanwha [1]

- Hapremec [1]

- HARDINGE [13]

- HARDINGE-BRIDGEPORT [1]

- HARRISON [4]

- HARTFORD [12]

- HASENCLEVER [1]

- HATASTAR [1]

- HATEBUR [2]

- HAU [1]

- HAULICK [4]

- HAULICK & ROOS [5]

- HAULICK + ROOS [1]

- HAULICK+ROOS [1]

- HAUNI-BLOHM [1]

- Haunstrup [1]

- HAUSER [19]

- HAUSER-SIP [1]

- HAUSLER [1]

- HAWE [1]

- HAZET [1]

- HBM [105]

- HD OHT (roll to roll) [1]

- HEAB [1]

- HEAD [1]

- HEBEFIX [1]

- HECHT [1]

- Heckert [14]

- HECKERT-STARRAG [2]

- Heckler & Koch [1]

- HECKLER & KOCH [1]

- HEDELIUS [9]

- HEDELIUS - Vertikal [3]

- HEGENSCHEIDT [3]

- HEGNER [1]

- HEID [1]

- HEIDELBERG [25]

- HEIDENHAIN [63]

- HEIDENREICH & HARBECK [7]

- HEIDENREICH & HARBECK [1]

- HEILBRONN [13]

- HEIN HESO [1]

- HEINRICH [1]

- Heinrichsgluck [1]

- HEINRICHSGLUECK [1]

- HEINRICHSGLÜCK [1]

- HEKUS [1]

- HEL - WITA [1]

- HELI COIL [4]

- HELIOS [1]

- Helios Com [1]

- HELLER [12]

- HELMERDING [12]

- Helmholz [2]

- HEMA [1]

- HEMBRUG [2]

- HENGSTLER [3]

- HENNINGER [1]

- HENSEL [13]

- HENSOLDT WETZLAR [1]

- HepcoMotion [1]

- HERA [11]

- HERAEUS [8]

- HERAEUS-VOeTSCH [1]

- HERBERT LINDNER [1]

- Herbert Nagel [1]

- HERBOLD [2]

- HERBORN [2]

- HERKULES [6]

- HERMES [8]

- HERMETIC [1]

- HERMLE [48]

- HERMLE (5-Achsen) [1]

- HERRMANN [2]

- HERTEL [3]

- HESKA [6]

- HESS [10]

- Hessap [1]

- HESSAPP [4]

- HESSE [8]

- HESSE by BEKA-MAK [31]

- HESSE by COILTECH [9]

- HESSE by DIRINLER [13]

- HESSE by DURMA [73]

- HESSE by FRESAN [5]

- HESSE by ISITAN [25]

- HESSE by JHL [3]

- HESSE by LFSS [36]

- HESSE by SAHINLER [23]

- HETO [1]

- HETTNER [1]

- HEUEN - CLOOS [1]

- HEUSER [2]

- HEWA [1]

- HEXAGON [1]

- Heyligenstaedt [17]

- HEZEL [3]

- HEZINGER [2]

- HHW [1]

- HIDROLIKSAN [21]

- HighWater [1]

- HILGELAND [1]

- Hilgers [1]

- HILLE [2]

- HILLER [1]

- HILMA [13]

- HISWeld [8]

- Hitachi [3]

- HITACHI SEIKI [1]

- HITACHI SEIKO [1]

- HITACHI-SEIKI [1]

- HITZESCHUTZTUCH [1]

- HIW HELMERDING [1]

- HK [1]

- HK CON [1]

- HKS [1]

- HM [10]

- HM MACHINERY [4]

- HM MACHINERY Tischbohrmaschine [1]

- HMB [5]

- HME [1]

- HMTCL [1]

- HNK MACHINE TOOL CO [3]

- Hobart [1]

- HOCHSTEIN [4]

- HOCHWERTIG [1]

- HOEFLER [7]

- HOFFMANN [5]

- HOFMANN [7]

- HOGG [1]

- Hohenstein [3]

- HOL-MONTA [1]

- HOLDWELL [2]

- HOLEX [2]

- HOLKE [1]

- Hollandprofiel [1]

- Holmatra [1]

- Holmatro [1]

- HOLZ-HER [1]

- Holzfraese [1]

- HOLZHER [1]

- HOLZKRAFT [7]

- HOMA / Gebr. Hoffmann [1]

- HOMAG [1]

- HOMMEL [1]

- HOMMEL HERCULES [1]

- HOMMELWERKE [1]

- HOPPECKE [1]

- HORIZON [1]

- HORMA [1]

- HORNUNG [1]

- HORSCH [1]

- Horstmann [2]

- HORVATH [1]

- HP [2]

- HPG [1]

- HPM [1]

- HRD [1]

- HS-AUTOMATION [3]

- HSA [1]

- HSD [1]

- HSP [1]

- HUBER [1]

- Hueller [1]

- Hunger [2]

- HURCO [25]

- HURON [20]

- HURTH [15]

- HURTH-MODUL [2]

- HUTT [2]

- HUVEMA [111]

- HUVEMA - Halbautomat [1]

- HVM [1]

- HWACHEON [5]

- HWR [2]

- HYDAC [1]

- Hydac/Mahle/Parker/Argo [1]

- HYDRAP [15]

- Hydraudyne [1]

- HYDRAULICA HYDAIR [1]

- HYDRAULIK-RING [1]

- Hydro Meca [1]

- Hydro Units [1]

- HYDROBAR [1]

- HYDROBULL [1]

- HYDROVANE [4]

- HYFRA [2]

- HYGIA [4]

- HYLATECHNIK [3]

- HÜLLER HILLE [2]

- HÜLLER – HILLE (MAG) [1]

- HÜLLER-HILLE [3]

- Hyllus [1]

- HYMAG [1]

- Hymo [1]

- Hymolift [2]

- HYSTER [1]

- HYUNDAI [14]

- HYUNDAI KIA [2]

- HYUNDAI WIA [2]

- HYUNDAI-KIA [1]

- HYWA [1]

- HYWEMA [1]

- HÄMMERLE [2]

- HÄMMERLE - GF BRUGG [2]

- Hässner - Bilz - Diverse [1]

- HÄUSLER [3]

- Häwa [1]

- HÖCKER-POLYTECHNIK [1]

- HÖFLER [3]

- i-tools [2]

- IBARMIA [7]

- IBERDRILL [10]

- IBERIMEX [3]

- IBERIMEX MVR (teilueberholt) [1]

- ICKING [1]

- IDE [1]

- IDRA [1]

- IEMCA [1]

- IFANGER [2]

- IFM [11]

- IFM ELECTRONIC [2]

- Ihermal Arc [1]

- IHG [1]

- IJR [1]

- ILT [1]

- Imada [1]

- IMATEC [3]

- IMCAR [3]

- Imec [1]

- IMES-ICORE [1]

- IMET [5]

- IMS [2]

- IMTI [2]

- INA [2]

- IND. GENERALI [1]

- INDEX [48]

- INDRAMAT [11]

- INDUCTION [1]

- INDUMA [1]

- INDUMASCH [9]

- INDUMASCH SIEGEN [1]

- INDUSTAR [1]

- Industriefilter-Service GmbH S [1]

- INDUSTRIEWERKBANK [1]

- INFRATIREA [3]

- INFRATIREA- ORADEA, RUMäNIEN [1]

- Infratireu [1]

- INGERSOLL [216]

- INGERSOLL-BOHLE [5]

- INK ZONE [1]

- INNOTOOL [3]

- INNSE [1]

- Inntool [2]

- INOX [3]

- INSTRON [1]

- INTEMACH [4]

- INTERTEST [1]

- INTOS [2]

- INVEMA [1]

- IPF [1]

- ipf electronic [2]

- IQ [1]

- IRCO [2]

- Irle [3]

- IRON / RDI Group [1]

- ISAM [1]

- ISCAR [4]

- ISELI [1]

- Isitan [1]

- ISMET [1]

- ISMET Werke [1]

- ISOMA [1]

- ITAL [4]

- ITALMACH [1]

- ITALMEC [3]

- ITB [1]

- ITEC [1]

- Iveco [1]

- IWK [3]

- IWK PEKRON [4]

- IWK Pressen [1]

- IXION [14]

- IXION AUERBACH [1]

- J&W [2]

- J. Behr [1]

- JACOBSEN [3]

- JAECKEL [1]

- Jaeckle [2]

- JAEGER [1]

- JAESPA [5]

- JAESPA - Vollautomat [1]

- Jafo [1]

- JAKOBSEN [4]

- JAMES BURN [1]

- James Ruben [1]

- JANTSCH [1]

- Japan [1]

- JAPAX [1]

- JAVA Machinery [1]

- JAVAC [3]

- JELSINGRAD [2]

- Jenaer [1]

- Jenbacher [1]

- JENNY [2]

- Jesco [1]

- JESPA [1]

- JESSERNIGG & URBAN [1]

- JESSEY [5]

- Jessey Champion [1]

- JETO [1]

- JIANHUA [2]

- Jinn Fa [1]

- JMC [1]

- JMTCL [4]

- Jnasen [1]

- JOBS [1]

- JOERG [3]

- JOHANN FISCHER [1]

- Johann Fischer Aschaffenburg [1]

- JOHNFORD [4]

- JOISTEN & KETTENBAUM [2]

- JOISTEN & KETTENBAUM [2]

- JONES & SHIPMAN [1]

- JONES SHIPMAN [1]

- Jones-Shipman [1]

- JONESCHEIT [1]

- JONGEN UNI-MILL [1]

- JOOS [2]

- JOPP [1]

- Jorg [14]

- JORNS (Verkauft) [1]

- JOTES [2]

- JP [1]

- Jrle [1]

- JS [1]

- Jsaw [3]

- JT [1]

- JTrans [5]

- JUARISTI [11]

- JuaristiZ/W [1]

- Jugenthal [1]

- JUKOMET [1]

- JULIUS [1]

- JUNG [21]

- JUNG / ISMET [1]

- JUNGENTHAL [7]

- JUNGHEINRICH [4]

- JUNGHEINRICH / AMEISE [1]

- JUNKER [12]

- JUTGER [1]

- JWELDING [16]

- K+K [1]

- K-W-H Langel Filtersysteme [1]

- KABELSCHLEPP [2]

- Kabinen [1]

- KADIA [4]

- Kaempf [1]

- KAESER [5]

- KAFO [2]

- KAI TEC [1]

- KAINDL [2]

- KAISER [25]

- KALTENABCH [1]

- KALTENBACH [27]

- KAMA KURA [1]

- KAMAX-BOSS [1]

- KAMI [35]

- Kao Ming [5]

- KAPEMA [7]

- KAPP [7]

- KARATS [3]

- KARL KLINK [7]

- Karmak [1]

- Karmetal [3]

- KARSTENS [10]

- KARSTENS / WEISS [1]

- KART [1]

- KASTO [37]

- KASTO - AUTOMAT [1]

- KASTO - Halbautomat [2]

- KASTO - Vollautomat [2]

- KASTO -Vollautomat [2]

- KAWASAKI [1]

- KEBE [1]

- KEF [1]

- KEHREN [1]

- KEILPART [1]

- KEKEISEN [4]

- KELCH [7]

- KELCH + Komet - Diverse [1]

- KELLENBERGER [33]

- KELLENBERGER UEBERHOLUNG [1]

- KELLER [1]

- Kemmerich [7]

- KEMPER [5]

- Kemppi [2]

- KEMT [3]

- Kennametal [4]

- KENT- HEAD [1]

- KEPROMA AG [1]

- KERN [5]

- KERN-DMT [1]

- Kesel [1]

- KESSLER [2]

- KETTENSTERN [1]

- KEULMAC [1]

- Keuro [1]

- KEYENCE [6]

- KIA [1]

- Kieper [1]

- KIESERLING [1]

- KIESERLING & ALBRECHT [2]

- Kiheung [9]

- Kikinda [2]

- KINEX [1]

- KING-CRAFT [1]

- KINGSLAND [4]

- KIRA [1]

- KIRBA [1]

- KIRSCHBAUM [1]

- KISTLER [3]

- KITAGAWA [2]

- KITAMURA [6]

- KITO [1]

- KIWA [2]

- KIWA EXEL CENTER [1]

- KJELLBERG [2]

- KLAASSEN [1]

- Klaeger [2]

- KLAIBER [1]

- KLAUKE [1]

- KLEIN [3]

- Kleine [1]

- KLEINEWEFERS [1]

- KLINGEL [3]

- KLINGELNBERG [25]

- KLINGELNBERG-OERLIKON [2]

- KLINGSPOR [1]

- KLOECKNER [1]

- KLOPFER [3]

- KLOPP [8]

- KLOPP-KORRADI [2]

- KLÄGER [1]

- KLÖCKNER MOELLER [2]

- KNAPP [1]

- KNAPP-DONAU [1]

- KNOLL [8]

- KNOTT [1]

- KNUTH [16]

- KNUTH / DURMA [2]

- KOBA [1]

- KOCEL [1]

- KOCH [1]

- KOCH Maschinentechnik GmbH [1]

- Koebau Multimat [1]

- Koelsch-Foelzer-Werke [1]

- KOENIG & BAUER [2]

- KOEPFER [3]

- KOEPFER / Wahli [1]

- KOEPFER 153 [1]

- KOESTER [1]

- Koettgem Flach [1]

- KOHCHIYAMA TECH [2]

- KOHLER [10]

- KOHLER / WEINGARTEN [1]

- KOHLER 6 HI [1]

- Kohlhoff Hygienetechnik Sailer [1]

- Koike [2]

- KOLARC [1]

- KOLB [24]

- KOLB-SCHMALTZ [1]

- Kolle [1]

- KOLOMNA [2]

- Kolster [1]

- KOMATSU [2]

- KOMET [2]

- Komplette Haerterei [1]

- KONDIA [7]

- Kone [2]

- Konecranes [2]

- KONHIDROLIKSAN [1]

- KONRAD SEIDLER [1]

- KOPAL [2]

- KORRADI [2]

- Kotterkop [1]

- KOVOSIT MAS [1]

- KOVOSVIT [1]

- Kownatzki-Reishauer [2]

- KRAEMER [2]

- KRAFT [145]

- KRAFT (Etech) [1]

- KRAFT (JAP) [4]

- KRAFT (Pinacho) [1]

- KRAFT (Robbi) [2]

- KRAFT (Sieg) [1]

- KRAFT (Skymaster) [1]

- KRAFT (SMTCL) [1]

- KRAFT (Tongtai) [2]

- KRAFT (YSP) [2]

- Kraft/Praise [3]

- KRAFT/Skymaster [4]

- KRAFTWERK [1]

- KRAMATORSK [1]

- KRAMER [7]

- KRAUSE [1]

- Krauseco-Mauser [2]

- KRAUSS-MAFFEI [3]

- KREBS / NORTON [1]

- KRIFFT & ZIPSNER [1]

- KROLLMANN [7]

- Kromas [1]

- Krupp [4]

- KRUPPS [1]

- KRUPS [11]

- KRYLE [1]

- KSB [1]

- KTR ROTEX [1]

- KTS [1]

- KUBOTA [1]

- Kuehlbad [1]

- KUEHLMITTELEINRICHTUNG [1]

- KUEPPERSBUSCH [1]

- KUESTERS, [1]

- KUESTERS, ALLSPEED [1]

- KUESTERS, KREFELD [82]

- KUESTERS,KREFELD [12]

- KUGEL MUELLER [2]

- KUHLMANN [1]

- KUKA [37]

- KULI [1]

- KUMBRUCH [1]

- KUNMING [1]

- KUNZMANN [11]

- KUPA [1]

- KUPER [3]

- KURT HECK [2]

- Kusters [1]

- KUSTERS, KREFELD [3]

- KÜSTERS, KREFELD [1]

- KÖLLE [4]

- KÖPFER [2]

- KÖSTER [1]

- L-TEC [1]

- LA RIGIDE [1]

- LACFER [3]

- LACO [1]

- Laeis [1]

- LAEPPLE [9]

- LAG [1]

- LAGUN [8]

- LAGUN FBF 1200 [1]

- LAMBERT - JOUTY [1]

- LANCELIN [1]

- Land Rover [1]

- LANDIS + GYR [1]

- LANDONIO [1]

- LANG [1]

- Langen [1]

- Langendorf [1]

- Langzauner [2]

- LANZ, Mannheim [3]

- LARF [1]

- LASCO [1]

- LASERPIN [1]

- Lastek [1]

- LAUFFER [12]

- LE [1]

- LE 250 C [1]

- LEADWELL [14]

- LECO [1]

- LED2 work [1]

- Lefort [1]

- LEHMANN [1]

- LEINEN [2]

- LEINHAAS [2]

- LEISTRITZ [4]

- LEITZ [6]

- LEITZ - HEXAGON [2]

- Lely [1]

- LENG [1]

- LENZE [3]

- LENZEN [4]

- LENZKES [3]

- LEUZE [4]

- Leybold Heraeus [1]

- LGB [4]

- LGB HURON [1]

- LIDKOEPING [2]

- LIEBER [1]

- LIEBERGELD multi-station press [1]

- LIEBHERR [17]

- LIECHTI [1]

- LIMONTA / EUROSLITTER [1]

- Lincoln [1]

- Lincoln Electric [1]

- LINCOLN ELECTRONIC [2]

- LINDE [12]

- LINDE - DIESEL [1]

- LINDE - GAS [1]

- LINDE T16-T20 [1]

- LINDNER [4]

- LINEAR ABRASIVE [1]

- Lingk und Sturzebecher [1]

- LINMOT [2]

- Lion [1]

- LIPTOVSKE STROJARNE [1]

- LISSE [1]

- LISSMAC [5]

- Lista [17]

- LISTA/DICK [1]

- LITZ [1]

- LIV [1]

- Livet [1]

- LMU [1]

- LNS [4]

- LOCH [1]

- LOCKFORMER [3]

- LODI [1]

- LODIFLEX CASER [1]

- LOESER [1]

- LOGITRANS [2]

- LOHENNER [1]

- LOIRSAFE [1]

- LOKOMA [1]

- LOMBARDO [1]

- Loos [1]

- LORCH [3]

- LORENZ [23]

- LOROCH [1]

- LOTZE [9]

- LOWARA [1]

- Lowener [1]

- LS Airless [1]

- LTA Lufttechnik [9]

- LUBRO Grisetti [1]

- LUFTKESSEL [1]

- LUIGART [3]

- LUNAN [1]

- LUTHER JORDAN [1]

- Luxmill [1]

- LVD [37]

- LWB STEINL [1]

- LÄPPLE [1]

- LÖW [1]

- LÖWER [15]

- M+A [6]

- M638 [1]

- MA.TE [7]

- MAAG [7]

- MABA [2]

- MABU [1]

- MACMOM / INAS [1]

- MACMON [5]

- MADER [1]

- MAE [9]

- MAEGERLE [1]

- Maerdian [2]

- MAFI [3]

- Mafi / IWT [1]

- MAG [1]

- MAGDEBURGER [2]

- MAHLE [2]

- MAHO [45]

- MAHO-GRAZIANO [1]

- MAHO-HANSEN [1]

- MAHR [12]

- Maidel [1]

- MAIER [3]

- MAILLEFER [1]

- MAJEVICA [1]

- MAKA [1]

- MAKINO [17]

- MAN [2]

- MAN + SIEMENS [1]

- MAN ROLAND [1]

- MAN-ROLAND [1]

- MANDELLI [2]

- MANNESMANN DEMAG [1]

- MANNESMANN-DEMAG [1]

- MANURHIN [1]

- MANURHIN MENTI [1]

- MANZONI [1]

- MAP [1]

- Mapelli [2]

- MAREL TVM [1]

- MARIO CARNAGHI [1]

- MARK [1]

- Markenlos [1]

- MARPOSS [1]

- MARTIN [4]

- Mas [15]

- MAS (KOVOSVIT) [1]

- Masch [2]

- Maschinenbauwerk Pleven [1]

- MASSEY FERGUSSON [1]

- MASTER HEAD SHOP [1]

- MASTERWOOD [6]

- MATCHMAKER [2]

- MATEC [10]

- MATHEYS [1]

- MATRA [6]

- MATRA JOHNFORD [2]

- Matricola [1]

- MATRIZENBLOCK [1]

- MATSUURA [9]

- MATTISON [1]

- Maus [1]

- MAUSER [8]

- MAWEG [1]

- MAX MUELLER [2]

- MAX MUELLER-GILDEMEISTER [1]

- MAX MÜLLER [4]

- MAX PIANCK [1]

- Maximart [2]

- Maximum [1]

- MAXION [11]

- MAY [2]

- MAY-RHODE-DOERRENBERG [1]

- MAYFRAM [1]

- MAYFRAN [1]

- MAYSS [1]

- MAZAK [81]

- MAZAK - CNC [4]

- MB [7]

- MB Bardowick GmbH [2]

- MBH [4]

- MBO [3]

- MC METALMECCANICA DI CENNI G: [1]

- MCM [3]

- MDM MECATRONICS [1]

- MDW [1]

- MEB [4]

- MEBA [13]

- MEBA - VOLLAUTOMAT [6]

- MECA [2]

- Meca Divimek [1]

- Mecatecnica [1]

- Meccaniche Moderne [4]

- MECOF [2]

- MEGEY [3]

- MEIER WERKE [1]

- MELCHIORRE [2]

- MELTEC [2]

- MEMMERT [1]

- Memoli [1]

- MENGELE [12]

- MENZEL [1]

- MEP [85]

- MEP - Halbautomat [14]

- MEP - VOLLAUTOMAT [10]

- MERCEDES BENZ [1]

- MERCEDES-BENZ [4]

- MERKLE [3]

- MERLI CLOVIS [3]

- MERLIN [1]

- MESSER [3]

- Messer Griesheim [4]

- MESSER GRIESHEIM / POLLRICH [1]

- Messgeraet Schatz GmbH [1]

- MESSMA-KELCH [2]

- MESSPLATTE [1]

- META [1]

- METABO [6]

- Metacon [2]

- Metal WAG [1]

- Metalas [1]

- Metallit [3]

- METALLKRAFT [16]

- METALLO [1]

- Metalwerk [1]

- METAS [1]

- METBA [2]

- METEC [1]

- METORA [4]

- METROM [1]

- Metron [1]

- METTLER TOLEDO [1]

- METZ [7]

- METZNER MASCHINENBAU [2]

- MEULEMAN [1]

- MEUSER [10]

- MEWAG [1]

- MEWAG IXION [1]

- MEWO [1]

- MEXPOL [2]

- MEYER & BURGER [1]

- MEYER-SCHNEGG [1]

- Meywald [2]

- MF-Eco Jet Pulse [1]

- MFD [1]

- MFD - HOESCH [5]

- MG [4]

- MH-inprocess [1]

- MIB [4]

- MICHAEL DECKEL [1]

- MICHAEL RIEDEL [3]

- MICHELIN [5]

- MICROCUT [4]

- MICROMILL [2]

- MICRON [1]

- MICROSTEP [2]

- MICROTURN [2]

- Midsaw [1]

- Miedema [1]

- MIESING [1]

- MIGATRONIC [3]

- MIGTRONIC Schweißgerät DIALO [1]

- MIKROCUT [1]

- MIKROMAT [5]

- MIKRON [54]

- MIKRON - HAAS [2]

- MIKRON AGIE CHARMILLES [2]

- MIKRON HAAS [1]

- MIKRON-AGIE CHARMILLES [3]

- Milko [1]

- Miller [2]

- MILLUTENSIL [2]

- MILUTENSIL [1]

- MIMATIC [2]

- Minilok [2]

- MININI [4]

- MINO / SAMO [1]

- MINUTE MAN [1]

- Mios [2]

- MIRAFU [1]

- MISAL [1]

- MISUMI [1]

- MITSUBISHI [7]

- MITSUBISHI Electric [1]

- MITSUI SEIKI [3]

- MITUTOYO [14]

- MITUTOYO KA-Counter [1]

- MIYANO [3]

- Mk Technology [1]

- MKF [1]

- Mobil Plastic [1]

- MODUL [1]

- MOELLER [4]

- MOESSNER [1]

- MOeSSNER REKORD [1]

- Molenschot [1]

- MOLL - MOTOR [6]

- MONDIALE [11]

- MONFORTS [18]

- MONNIER & ZAHNER [2]

- Monnier + Zahner [1]

- Monofap [1]

- MonTech [1]

- MOORE [3]

- MORANDO [2]

- MORARA [2]

- MORI SEIKI [63]

- MORI-SEIKI [1]

- MOSA [1]

- MOSER [1]

- MOTOM [1]

- MOTOMAN [3]

- Motorenbau Niedernhall [1]

- MPK [7]

- MPT [1]

- MRF [1]

- MSO [2]

- MT CUT [1]

- MTA [1]

- MTcut [1]

- MTE [2]

- MTM [1]

- MTorres [1]

- MUBEA [15]

- MUEGA [1]

- MUELLER [25]

- Mueller Martini [1]

- MUeLLER OPLADEN [1]

- MUELLER PAUL [1]

- MUELLER-GEFREES [1]

- MUELLER-WEINGARTEN [2]

- Muelltonnenkipper [1]

- MUENSTER [1]

- MUHR & BENDER [7]

- Muller [1]

- MULTIFIX [75]

- MULTIFIX C [1]

- MULTIFORM [1]

- Multimig [1]

- MUM [1]

- Munk [1]

- MUNK vari Plus [1]

- MUNSTER [1]

- MUNTHE-MONOPOL [1]

- MURATEC [6]

- Murr [4]

- MURR Elektronik [2]

- MVD [1]

- MVE BAUART VDF [1]

- MYANO [2]

- Myford [1]

- müga [1]

- MÜGA (teilueberholt) [1]

- MÜLLER [35]

- MÜLLER - WEINGARTEN [2]

- MÜLLER INNSBRUCK [1]

- MÜLLER WEINGARTEN [2]

- MÜLLER-WEINGARTEN [3]

- MÄDER [1]

- MÄGERLE [2]

- MÖSSNER [5]

- MÖSSNER REKORD [1]

- N/A [1]

- Nabertherm [2]

- NACKE + GEWEFA [1]

- NAGEL [15]

- NAKAMURA [8]

- NAKAMURA TOME [4]

- NAMSUN [1]

- NARDINI [2]

- NARVIK [6]

- NATIONAL INSTRUMENTS [1]

- Naturhartgestein [1]

- Naxos [1]

- Naxos Union [5]

- NAXOS-UNION [4]

- NAXOS-UNION EMAG [1]

- Nederman [2]

- NEEF [1]

- NEFF [8]

- NELA ROVI [1]

- NELSON [3]

- Neopost [1]

- NESTRO [4]

- Netter [1]

- NEU [1]

- NEUHHAEUSER [1]

- NEUMANN [2]

- NEWS [1]

- NEXTURN [1]

- nicht ersichtlich [2]

- NICOLAS CORREA [2]

- Nieland [2]

- NIIGATA [3]

- NIKKEN [3]

- NILES [11]

- NILES-SIMMONS [1]

- NILFISK [2]

- NILFISK ALTO [1]

- NIMAK [13]

- Nippon [1]

- NISSHINBO [1]

- NITTO KOHKI Co. [1]

- NKO [11]

- NN [304]

- NOBLE & LUND [1]

- NOLZEN [3]

- NOMOCO [2]

- NONAME [4]

- NORD [2]

- NORD / Getriebebau NORD [1]

- NORGREN [1]

- NORMATIC [1]

- NORTE [3]

- NOSOTTI [1]

- NOSSTEC ( LUNA ) [3]

- NOVALITH [2]

- NOVOTECNIC [1]

- NOVUS [1]

- NPM - Noris [1]

- NRA [1]

- NSM MAGNETTECHNIK [1]

- Numberall [1]

- NYDALS [1]

- O&K [1]

- OBRU [5]

- OCÉ [2]

- OCHSNER [1]

- OERLIKON [12]

- OERLIKON-BOEHRINGER [2]

- OERLIKON-KLINGELNBERG [1]

- OERTLI [1]

- OERTLIN [1]

- OEVERMANN [1]

- OEVERMANN & NIEDRINGHAUS [1]

- OHLER [2]

- Okamoto [3]

- OKAYA [2]

- OKK [4]

- Okoma [1]

- OKUMA [27]

- OLAER [1]

- OMAG [2]

- Omca [1]

- OMCN [6]

- OMCN / BAHCO [1]

- OMERA [1]

- OMES [1]

- OMG [1]

- OMRON [1]

- ONA [1]

- ONA-DATIC [1]

- ONSAL [1]

- OOYA [1]

- Opitz [1]

- OPPOLD [3]

- OPTIdrill [2]

- OPTIdrill Tischbohrmaschine [2]

- OPTIMUM [21]

- OPTREL [2]

- ORSTA [1]

- ORSTA Hydraulik [1]

- ORWAK [1]

- OSG [1]

- OSTAS [24]

- OTC [2]

- OTTO MÜLLER [1]

- Overige machines/toebehoren [1]

- OZMACHINE [2]

- P.B.R. [1]

- P/A [1]

- PA [1]

- PADBERG-CEPA [2]

- PADOVANI [2]

- Palette 1 [1]

- Palette 2 [1]

- Palette 3 [1]

- Palette 4 [1]

- Palette 5 [1]

- Palette 6 [1]

- Palette 7 [1]

- PALETTEN [1]

- Pallmann [1]

- PAMA [6]

- PANHANS [9]

- PANTHER [1]

- Papierbandfilter [1]

- PARKER [6]

- PARPAS [2]

- PARX [1]

- PASQUINO [2]

- PAV [1]

- PAVENTA [1]

- PBR [2]

- PEDDINGHAUS [33]

- PEDRAZZOLI [1]

- PEE WEE [1]

- PEE-WEE [9]

- PeeWee [1]

- Pefra [1]

- Pegard [6]

- PEGAS - VOLLAUTOMAT [1]

- PEGASUS [1]

- PEHAKA [3]

- Pehu [1]

- PEI [1]

- PEISELER [7]

- PEISLER [1]

- PEL [1]

- PELI [1]

- PELISSIER [1]

- PENSOTTI [1]

- PEPPERL + FUCHS [1]

- Pepperl+Fuchs [3]

- PERFECT [1]

- Perini Spartaco [1]

- PERSICO [1]

- PERSKE [2]

- Perthen Mahr [1]

- PETER JANSKY [1]

- PETER WOLTERS [1]

- PETEWE [1]

- Pewag [1]

- PFAFF [2]

- Pfaff Silberblau [1]

- PFAUTER [18]

- PFAUTER-GLEASON [1]

- PFAUTER/RICHARDON [1]

- PFEIFER [3]

- PFEIFFER [1]

- Pferd [4]

- PFIFFNER [1]

- Philips [2]

- Phoenix [3]

- PHOENIX Contact [2]

- PHÖNIX [1]

- PIAB - Niessen [1]

- PIERRET [2]

- PIESOK [2]

- PIETRO CARNAGHI [2]

- Pietrocarnaghi [1]

- Piller [2]

- PILZ [20]

- PINACHO [13]

- PITTLER [4]

- PIZZI [1]

- PLACKE [5]

- PLAN [1]

- PLANK / WMW Heckert/Saalfeld [1]

- PLANOLITH [1]

- Planscheibe [6]

- PLANSEE [6]

- Planspiralfutter [1]

- PlasmaCut [3]

- Plattenfeld [1]

- Plus One [1]

- PME [4]

- PMH [1]

- POLAR [3]

- Polar Mohr Lasercutter [1]

- Poli Tape [1]

- POLO [1]

- POLYGRAPH [2]

- Polymat [1]

- POMINI-FARREL [2]

- PONAR, POLEN [1]

- PONTIGGIA [2]

- POREBA [22]

- POSALUX [3]

- POSMILL [1]

- Post [1]

- Powasert [1]

- Powerlift [1]

- Powertherm [1]

- PRAMAST [2]

- PRB [1]

- PRECISE PVSF-1 [1]

- PREH [1]

- PREISSER [2]

- Premac [1]

- PresseRoss [1]

- PRESSTA-EISELE [1]

- PREVIERO [1]

- PRIMA INDUSTRIE [1]

- Primat [1]

- PRIMINER [1]

- Prinzing [2]

- PRO-FACE [3]

- Pro-System-Verpackungstechnik [1]

- PROBAT [3]

- PROFI [2]

- PROFI PRESS [7]

- PROFIPRESS [11]

- PROFIROLL [1]

- PROFIROLL BAD DUEBEN [1]

- Promatic [1]

- PROMECAM [2]

- PROMOTECH [1]

- PROTAC ZAAR [2]

- PROTH [3]

- PROTUS [1]

- Pruefkabine [1]

- PRVOMAJSKA [1]

- PRÄWEMA [1]

- PSM [2]

- Pugno [1]

- PULLMAX [5]

- PULS [1]

- PULZER [1]

- PUMA [1]

- PUSKAS SIERRA [1]

- PWK [2]

- PWS [26]

- PWZ [1]

- QIQIHAR [1]

- QUANTUM [3]

- Quaser [8]

- QUASER (5-ACHSEN) [2]

- QUICK TECH [1]

- QUICKWOOD [2]

- R+R [1]

- R+S Technik [1]

- RAAKO [1]

- RABBA [10]

- RABOMA [5]

- RADLER & RUF [1]

- RAFAMET [6]

- RAGNAR [6]

- RALCitalia [1]

- RAMBAUDI [2]

- Rambo [1]

- RAMO [1]

- RAPID [9]

- RAPIDE [3]

- RAS [29]

- RASKIN [1]

- Raskin Suisse [1]

- RASOMA [1]

- RASTER [5]

- RASTER ZEULENRODA [1]

- RAU [1]

- RAUCH [2]

- RAUHEIS [1]

- RAUSCH-GRATOMAT [1]

- RAVENSBURG [13]

- Ravensburg P 30 [1]

- RAZIOL [1]

- RCT [1]

- RDB [3]

- RDB / PELMA [1]

- REA [3]

- RECKERMANN [12]

- RECKMANN [1]

- RECYCLINGBOX AMBRA [1]

- REFORM [6]

- REFU [1]

- REGLOPLAS [1]

- REHM [3]

- REHNEN [1]

- REICH [1]

- REICHENBACHER [1]

- REICHERTER [1]

- REICHLE & KNÖDLER [1]

- REIDEN [11]

- REINECKER [1]

- REINECKER KOPP [1]

- REINHARD [1]

- REINHARDT [2]

- REIS [23]

- REISHAUER [24]

- REITER [1]

- REITZ / LAMMERS [1]

- REKORD [1]

- REM [3]

- REMA [8]

- REMAK-Keil GmbH [1]

- REMS [1]

- RENFROE CLAMP [1]

- RENISHAW [4]

- RENNER [5]

- RENZ [2]

- REO [1]

- REP [1]

- REXON [1]

- REXROTH [11]

- REXROTH BOSCH [3]

- REXROTH,PARKER, VICKERS, FESTO [1]

- RFR [1]

- RGA [1]

- RHEWA [1]

- RHODES [1]

- RHONA [1]

- RHTC [11]

- RHTC - Portalpresse [1]

- RIBON [1]

- Richter [1]

- RICHTER [2]

- RICHTER-IWK [1]

- RICHTWERK [2]

- RICHYOUNG [1]

- Ricoh [1]

- RIDGID [2]

- RIDGID Kollmann [1]

- RIEDEL [1]

- RIELLO [3]

- RIETSCHLE [1]

- RINECK [1]

- RINGLER [1]

- RINGLER - Kaercher [1]

- RITTAL [4]

- RIVELICA [1]

- RIVETT [1]

- Robamat [2]

- Robbi [5]

- ROBU [1]

- RODOLFO COMERIO [1]

- ROEHM [15]

- ROEHM (VERMUTLICH) [1]

- Roehm,Forkarth [1]

- ROELL + KORTHAUS [1]

- Roemheld [3]

- Roescher [1]

- ROEWAG [1]

- ROEWI [1]

- ROFIN [1]

- Rohbi [1]

- ROHDE & DÖRRENBERG [1]

- Rohm [6]

- ROLLENBAHN [11]

- ROLLERS [1]

- ROLLMAK [6]

- ROLLOMATIC [1]

- Rollwalztechnik [4]

- ROMAI [2]

- ROMI [2]

- ROQUET [1]

- ROSA [3]

- ROSA ERMANDO [1]

- ROSCHER & EICHLER [1]

- ROSENBACH [1]

- ROSENBOOM [2]

- ROSENDAHL [1]

- ROSI [1]

- ROTAPRINT [1]

- ROTATHERM [1]

- Rothenberger [3]

- ROTO MORS [1]

- Roto Record [4]

- ROTOX [1]

- ROTUS [1]

- Roundo [7]

- Rowac [3]

- RSA [5]

- RTK [1]

- RUCHSER [27]

- RUCOCO [1]

- RUD [1]

- RUEBENACH [1]

- RUECKLE [1]

- RUESCH [1]

- Ruhrgetriebe [2]

- Ruhrmann [1]

- RUNDTISCH [2]

- RURACK [5]

- RUWAC [1]

- RÜBENACH - BONN BEUEL [2]

- RÜCKLE [1]

- RÜHLE [1]

- RYOBI [1]

- RÖCHER [1]

- RÖDERS (HSC) [1]

- RÖHM [43]

- RÖHM (wahrscheinlich) [1]

- RÖLTGEN [1]

- RÖSLER [2]

- S&S [7]

- S/P [1]

- Saacke [5]

- SAB [1]

- SAC [1]

- Sacem [1]

- SACHMAN [2]

- SACK & KIESSELBACH [2]

- Saeilo [5]

- SAF [6]

- SAFAN [11]

- SAFED [1]

- SAFEWAY [2]

- SAFOP [1]

- SAFOP LEONARD [2]

- SAGITA-BEYELER [1]

- SAGOP [2]

- SAHINLER [8]

- SAHN [1]

- SAIMP [1]

- SALTEC [1]

- SALVAGNINI [1]

- SALVAMAC [6]

- SAMAG [1]

- SAMPUTENSILI [1]

- Samsomatic [1]

- Samsung Smec [1]

- SAMU [1]

- SAMUR [1]

- SAN ROCCO [1]

- SANDERS [26]

- Sandingmaster [1]

- SANDT [2]

- SANDVIK [52]

- SANDVIK COROMANT [48]

- SANGIACOMO [1]

- SARO [2]

- SARTORIUS [2]

- SARTORIUS Ultra-Cleaner [1]

- SAS Sondermaschinen [1]

- SAT [1]

- SATO [1]

- SATRONIK [1]

- SATT Control [2]

- SATT Electronics [2]

- SATZINGER [1]

- SAUTER [1]

- SAVAGE [1]

- SAW KING [1]

- SAY-MAK [2]

- SBC [3]

- SBN [3]

- SBN Tischbohrmaschine [1]

- Scaffsystem [1]

- SCANSONIC [1]

- SCANTOOL [6]

- SCARABAEUS / TA Instruments [1]

- SCHAAL [1]

- SCHAEFER [3]

- SCHAERER [4]

- SCHAFBERGER + SPROEDHUBER [1]

- SCHAFFNER [4]

- SCHAFTFRAESER [1]

- SCHANBACHER [5]

- SCHARF WESTFALIA [1]

- SCHARF, AIRTEC [1]

- Scharmann [29]

- SCHARRINGHAUSEN [3]

- SCHAUBLIN [9]

- SCHAUDT [10]

- SCHECHTL [8]

- SCHEER [5]

- SCHEER & CIE [1]

- SCHEFER [1]

- SCHENCK [7]

- SCHERER FEINBAU [3]

- SCHIES5 [1]

- SCHIESS [16]

- SCHIESS -DEFRIES [1]

- Schiess Defries [1]

- SCHIESS Froriep [1]

- SCHIESS- FRORIEP [4]

- SCHIESS-FRORIEP [13]

- SCHIESS-KOPP [1]

- SCHIESS-NASSOVIA [1]

- SCHIMKE+HAAN [2]

- SCHIMPKE-HAAN [1]

- Schirmer Plate Simpelkamp SPS [1]

- SCHLATTER [1]

- SCHLEICHER [13]

- Schleicher Ideal Edelhoff [1]

- SCHLEIFPOWER [2]

- SCHLEIFSPINDEL [1]

- SCHLICK [2]

- SCHMALTZ [2]

- SCHMALZ [1]

- SCHMERSAL [7]

- SCHMID [4]

- SCHMID-KOSTA [1]

- SCHMIDT [3]

- SCHMIDT Tempo [1]

- SCHMIDT-TEMPO [1]

- Schmitz [2]

- SCHNEIDER [16]

- SCHNEIDER SENATOR [1]

- SCHNUTZ [2]

- SCHOEN [14]

- SCHOLLE [2]

- SCHORCH [1]

- SCHRADER / OWR [1]

- SCHRAMM & LICHNER [1]

- SCHRAUBSTOCK [1]

- SCHRAUBSTOCK HYD. [1]

- Schreiber [2]

- SCHROEDER [11]

- SCHRÖDER [6]

- SCHRÖDER FASTI [1]

- SCHUBERT [2]

- SCHUECO [2]

- SCHUETTE [1]

- SCHUKO [2]

- SCHULER [33]

- SCHULER HYDRAP [1]

- SCHULER SMG [1]

- SCHULER-HYDRAP [1]

- SCHULER-WEINGARTEN [1]

- SCHUMACHER, System TRENNJÄGER [1]

- SCHUMAG [2]

- SCHUNK [32]

- Schutzeinrichtung Fraesm. [1]

- Schwartze-Wirtz [1]

- SCHWARZ [2]

- SCHWARZE-WIRTZ [4]

- SCHWEGLER [1]

- Schweisskraft [3]

- SCHWERDTFEGER [1]

- SCHÜTTE [9]

- SCHÄFER [13]

- Scledum [1]

- SCM [4]

- SCORBOT - ER [1]

- Scotchman [1]

- SCRIPTA [2]

- SCS [1]

- SCULFORT [1]

- Seacom [1]

- Secmu [1]

- SECO [38]

- SECODEX [3]

- SEDIN [4]

- SEI Laser [1]

- SEIGER [7]

- SELECT [1]

- Self-leveling cross line laser [1]

- SEMA [1]

- SEMA BRIO [1]

- SEMAX [1]

- SEMPELL [1]

- Sempuco [1]

- SERAPID [1]

- SERTOM [1]

- SETTIMA [1]

- SEVERT [4]

- SEW [6]

- SEW-EURODRIVE [7]

- SGP [1]

- Shadomaster [1]

- SHARP [1]

- Shigiya [1]

- Shoda Techtron [1]

- Shop Press [1]

- SHORE [1]

- SHW [7]

- SIA [1]

- SIAT [1]

- SIC [1]

- Sicap [1]

- Sices [2]

- SICHELSCHMIDT [1]

- SICK [9]

- SICMI [61]

- SIDEROS [11]

- Siduza [1]

- SIEGERT SHT [8]

- SIEGMUND [89]

- SIEGMUND - ZUBEHOER [8]

- SIELEMANN [3]

- SIEMENS [337]

- SIEMPELKAMP [1]

- SIG [1]

- SIGMA [1]

- SIKO [2]

- Sikoplast [1]

- SILISTRA [2]

- SILIT [1]

- SILVERLINE [1]

- SilverSpatz CLL-R [1]

- SIMA [1]

- SIMASV [3]

- SIMAT [2]

- SIMEK [1]

- Simep [1]

- SIMON [3]

- SIMPAC [1]

- Simpelkamp, Reinartz [1]

- SIMPLON [1]

- SINGLE [2]

- SINTO [1]

- Sintris [1]

- SINUS [2]

- SIP [13]

- SIP - Hauser [1]

- Sip Hauser [1]

- SIT [3]

- SIXIS [1]

- SK - 40 [1]

- SKET [1]

- SKF [5]

- SKF Lager [1]

- SKODA [27]

- Sky Master - KRAFT [1]

- SLM [1]

- SmartScope [2]

- SMC [22]

- SMEC [1]

- SMERAL [2]

- SMG [14]

- SMID [2]

- Smitweld [2]

- SMM [1]

- SMP [1]

- SMS EUMUCO-MEER [1]

- SMT [2]

- SMT - PULLMAX [2]

- SMT Pullmax [1]

- SMTCL [1]

- SMW [2]

- SMW / EMAG [1]

- SMW AUTOBLOK [1]

- SMW-AUTOBLOK [1]

- SNIJSTAAL FABRICAGE B.V. [1]

- SNK-SHIN NIPPON KOKI [1]

- SOLID [9]

- SOMAB [5]

- SOMET [2]

- Somua [1]

- SOMUA CNC [1]

- SONY [1]

- SOPREM [8]

- SORALUCE [20]

- SOYER [2]

- SPALECK [3]

- SPANDAU [2]

- SPANFIX [1]

- Spannboecke [2]

- SPANNFIX [3]

- Spannfutter [1]

- SPANNTOP [1]

- SPANNZANGEN [5]

- Speedomatic [1]

- Spengler Dire76ct [1]

- SPERONI [1]

- SPINNER [19]

- SPIRAL [2]

- SPISIN [1]

- SPOERRI [1]

- SPV [1]

- STAEUBLI [1]

- STAHL [4]

- STAHL Ludwigsburg [2]

- Stahlgruppe [1]

- STAHLSEIL [1]

- STAHLWERK GERMANY [1]

- STAMA [11]

- STAMA ROBODRILL [2]

- STANEXIM [2]

- Stanko [1]

- Stanko [27]

- STANKO SEDIN [1]

- Staplerkehrmaschine [1]

- Star [16]

- Star / SFB Büchele [1]

- Staral [1]

- STARK [2]

- STARRAG [3]

- STARRAG HECKERT [2]

- STARRAG-HECKERT [3]

- STARTRITE [3]

- Starvision [1]

- STEFOR [1]

- STEGHERR [2]

- STEINBOCK BOS [1]

- STEINEL [3]

- STEINER [3]

- STEINLE [1]

- STEINMEYER [2]

- STEMA [1]

- STEMKE [1]

- Stenhoj [1]

- STENHOJ [2]

- STEPHAN [2]

- STIEFELMAYER [6]

- STIERLI - BIEGER [2]

- STIHL [1]

- Still [2]

- Stimin / Volz [1]

- STM [1]

- STOLLE [8]

- Storebro [1]

- STORK [5]

- STRAMA [1]

- Strands [1]

- STRAPEX [2]

- Strausak [1]

- STRECKER [2]

- Strekwals [1]

- STRIFFLER [2]

- STROHM [3]

- STROJAREN PIESOK [1]

- STROJARNE [1]

- STROJTOS [1]

- Stroter [1]

- STUCKMANN & HILLEN [1]

- STUDER [12]

- STUDER NR. 325 [1]

- STUeCKMANN & HILLEN [1]

- STUERMER [1]

- STUHLMANN [2]

- Stumpf [1]

- STÜCKMANN + HILLEN [2]

- Style [2]

- STÖCKEL [1]

- STÖLTING [1]

- SUGINO ZIPPEL [1]

- SUHL [1]

- SUHNER [2]

- Sullair [1]

- SULZER [1]

- SUMITOMO-SHIBAURA [2]

- SUNDSTRAND [1]

- SUNNEN [8]

- Superjet Eutalloy [1]

- SUPERMAX [2]

- SUPFINA [2]

- SW [2]

- SW SCHWÄBISCHE WERKZEUGMASCHIN [2]

- SW-SCHWäBISCHE WERKZEUGMASCH. [2]

- SW-TOOLS [1]

- Swiss Kraft [1]

- SWISSTOOL [1]

- Sybrandy [1]

- SÜDMETALL [1]

- SYIL [1]

- SYKES [1]

- SYMCO [1]

- Systec [1]

- SZIM [1]

- T-NUTEN Aufspannplatt [1]

- T-NUTEN Aufspannplatte [1]

- TACCHELLA [2]

- TACCHI [6]

- TACTIX [1]

- Tadu [4]

- Tai Piin [1]

- TAILIFT [7]

- Takang [1]

- Takeda [1]

- TAKEDA KIKAI [1]

- TAKISAWA [6]

- TAM [1]

- Tandem-Heckkipper [1]

- TAPROGGE [2]

- Tauring [2]

- TBT [4]

- TCI [2]

- TCM [1]

- TCR [1]

- TEAP [1]

- TECALEMIT [1]

- TECHNICA [4]

- TECHNICA (SCHWEIZ) [1]

- TECHNIKA [1]

- TECHNO-JET [1]

- TECMASCHIN [1]

- TECNA [3]

- TEDERIC [1]

- TEHAG [3]

- Teichmann [1]

- TEKA [8]

- Tekna [1]

- TELEMECANIQUE [3]

- TELWIN [2]

- TENNANT [1]

- TERENZIO [1]

- TESA [5]

- TF GmbH [1]

- TFL [1]

- THEIMER [1]

- THEIS [1]

- THERMAL ARC [1]

- THERMAL ARC [1]

- THERMCRAFT [1]

- Thermofin GmbH (Hans Günter Gm [2]

- THIEL [5]

- THIELENHAUS [3]

- THIELER [1]

- Thijssen [1]

- THK [2]

- TIBO [2]

- TIEDE [1]

- TILGERT [2]

- Timesavers [4]

- TIRA [1]

- TITAN [1]

- TITAN (PAMA) [2]

- TITAN ONSAL [1]

- Titan Umaro [1]

- TITAN-PAMA [1]

- TITEX [1]

- TITEX PLUS [4]

- TITEX, BECK, MAY [1]

- TKD [1]

- TOKAI [1]

- Tone Fan [1]

- TONGIL [1]

- Tongtai [3]

- Tool-Temp [1]

- TOOLPOWER [8]

- Top Automationi [1]

- TOPPER [1]

- ToRen [21]

- TORNOS [11]

- TORNOS-BECHLER [2]

- TOS [94]

- TOS - KURIM [1]

- TOS / MAS [1]

- TOS HOL-MONTA [1]

- TOS KURIM [2]

- Tos Varnsdorf [1]

- TOS Warnsdorf [1]

- TOS-CETOS [1]

- TOS-HOSTIVAR [1]

- TOS-KURIM [1]

- TOS-VARNSDORF [2]

- TOS/BLANSKO [1]

- TOSHIBA [3]

- TOSHIBA-SHIBAURA [1]

- TOSOKU [2]

- TOX [3]

- TOX PRESSOTECHNIK [3]

- TOX-Pressotechnik [4]

- TOYODA [6]

- Toyoseiki [1]

- TOYOTA [3]

- Tractel [1]

- TRAK [1]

- TRANSFLUID [2]

- TRASFOR [1]

- TRAUB [15]

- TRENNJAEGER [8]

- TRENNJÄGER [2]

- TrennSo-Technik [1]

- TRENS [1]

- Trepel [1]

- TRIMILL [1]

- TRIMWEX [3]

- TRIPAN [112]

- Tripel [1]

- TRIPET [1]

- TROESTER [5]

- Tronzadoras [1]

- TRUMPF [107]

- TRUMPF 3 D [1]

- TRUMPF TRUMATIC [2]

- TS Testingservice GmbH [1]

- TSCHUDIN [6]

- TSUGAMI [3]

- TTMC [1]

- TUBEND [1]

- Tuel Kelch [1]

- Tuenkers 800 Anleimmaschine [1]

- TUGRA [3]

- TUL KELCH [2]

- Tul Kelch System [2]

- TUMAC [1]

- TURBO VACUUMENTATION [1]

- TURNIER [1]

- Tuwei [1]

- TUWI [1]

- TVB [1]

- TÜNKERS [1]

- Tyrolit [5]

- UAS [1]

- UCIMU [1]

- UDSSR [1]

- Uhrhan & Schwill [2]

- ULMER [1]

- ULMIA [2]

- Ultra [1]

- UMA - SZM [1]

- UNBEK. [2]

- UNBEKAANT [1]

- UNBEKANNT [516]

- UNBEKANNT / UNKNOWN [3]

- UNBEKANNT/NOT KNOWN [4]

- Unbekannt/unknown [8]

- UNBEKANT [1]

- UNGERER [6]

- UNICRAFT [14]

- Unicum [1]

- Unimax [2]

- UNION [36]

- UNION-BIELEFELD [3]

- UNIQUE [1]

- UNISIGN [8]

- UNITECH [2]

- UNITEK [5]

- UNIVERSAL [1]

- UNIVERSAL Hydraulik [1]

- Universitaet Rosenheim [1]

- UP-HELFERT [1]

- URBAN [1]

- UTAS [1]

- Uttis [1]

- UVA [1]

- UWM [35]

- V-Blok [3]

- V-TRADE [4]

- V.S.F [3]

- VAG [3]

- VALLA [1]

- VALTRA [1]

- Van de Graaf [5]

- Van Der Graaf [1]

- Van Voorden [1]

- VARIAN [1]

- VB DOCK LOCK [1]

- VDF [5]

- VDF BOEHRINGER [5]

- VDF H & H [1]

- VDF HEIDENREICH & HARBECK [2]

- VDF- BOEHRINGER [1]

- VDF-BOEHRINGER [10]

- VDF-HEIDENREICH & HARBECK [2]

- VDF-HEIDENREICH & HARBECK [1]

- VDF-WOHLENBERG [1]

- VEB [8]

- VEB Blema Gotha [1]

- VEB MIKROMAT [1]

- VEB Typ 2 [1]

- VEB, BAD- SALZUNGEN [1]

- VEB-MIKROMAT [1]

- Vector [1]

- Veenstra [1]

- VENTI OELDE [1]

- VEP AUTOMATION [1]

- Verlinde [2]

- Vermtl. Kabbert [1]

- Vermutl. BOSCHERT [1]

- VERNIER [2]

- VERNIER GSP TRENS [1]

- Versa [1]

- VERTEX [1]

- VETTER [2]

- VEVOR [1]

- VICTOR [13]

- VIDEOJET [1]

- VIDMAR [1]

- Vierbackenfutter [1]

- VIGANO/RIVA [1]

- Viking [2]

- VIPER [1]

- VITAX [2]

- VITRO [1]

- VMA [1]

- VOBAU [1]

- VOEST [1]

- VOEST - ALPINE STEINEL [1]

- VOEST ALPINE [1]

- VOEST- ALPINE [1]

- VOEST-ALPINE [3]

- VOEST-ALPINE STEINEL [3]

- VOEST-ALPINE-WEIPERT [1]

- VOETSCH [1]

- VOGEL [4]

- VOGEL & Noot [1]

- VOGT [1]

- VOGTLAND [2]

- VOITH- Traun [1]

- VOJUS [1]

- VOLLMER [3]

- VOLTA [1]

- VOLZ [1]

- VOMA [1]

- VON ARX [1]

- Vorwerk [1]

- VOUMARD [4]

- Vremac [1]

- VSF [1]

- W. Paul Müller [1]

- W.Z [1]

- WABAMA [2]

- WACHTLER [1]

- WADRA [1]

- WAFIOS [1]

- WAGNER [14]

- WAGO [3]

- WAHLI [1]

- wahrscheinl. FISCHER [1]

- wahrscheinl. KAISER & KRAF [1]

- wahrscheinl. ROeHM [1]

- WaKra [1]

- WALDRICH [1]

- WALDRICH COBURG [4]

- WALDRICH SIEGEN [1]

- WALDRICH-COBURG [17]

- WALDRICH-SIEGEN [8]

- Walker Braillon Magnetics [1]

- WALKER MAGNETIC [1]

- Walker-Hagou [2]

- Wallecan [1]

- WALTER [71]

- WALTER & MACKH [1]

- Walzwerk [2]

- WANDERER [4]

- WANZKE [7]

- WAX [1]

- WDS JAPAX ISMET [1]

- Weber [5]

- WEBO [12]

- Webster & Bennett [1]

- WECON [1]

- WEDEVAG [1]

- WEDI PRESSTA 7000 [1]

- WEELABRATOR [1]

- WEG [1]

- Wegoma [1]

- Wegoma -STRIMA [1]

- WEILER [37]

- WEIMA Maschinenbau GmbH [1]

- WEINBRENNER [9]

- WEING [1]

- WEINGARTEN [62]

- WEINIG [15]

- WEINIG, GOETZINGER [1]

- Weinig, Gubisch, Panhans [1]

- WEIPERT [6]

- WEISS [3]

- WEISSER [7]

- WEISSER HEILBRONN [4]

- WEISSER-HEILBRONN [2]

- Welca [1]

- WELDING [15]

- WELE [2]

- Well Sayang Machinery [1]

- WEMAS [1]

- WEMHOENER [1]

- WENDEL [1]

- WENDT [2]

- WENIG [6]

- WENZEL [3]

- Werkzeugaufnahmen [3]

- WERKZEUGSCHRANK [4]

- Werkzeugtraeger [3]

- WERNER [1]

- WERNER, FRITZ [1]

- WERNER-WERKE [1]

- WERTH [4]

- Wescap [1]

- WESPA [1]

- Westeneng [1]

- Westofen [1]

- WESTPHAL [1]

- WEVERK Karlstadt [1]

- WEWAG ECONOMY [2]

- WEYRAUCH [1]

- WFL [4]

- WFL 5-ACHSEN [2]

- WFT [3]

- WG [1]

- WGW [5]

- WHM [2]

- WIDAX [78]

- WIDAX-HEINLEIN [1]

- WIDIA [4]

- WIEDEMANN [2]

- Wiedenbach [1]

- WIEGER [6]

- WIELAND [1]

- Wiesemann MAW [1]

- WILA [1]

- Wild Barfield [3]

- WILD-LEITZ [1]

- WILHELM OELZE [1]

- Wilhelm Spiess [1]

- WILHELMSBURGER [3]

- WILKINS & MITCHELL [1]

- WILLEMIN MACODEL [2]

- Wilson Jones Company [1]

- WIMO [1]

- WINDHOFF [4]

- Winkelbieger [1]

- Winslow [1]

- WINTER [1]

- WINTERFELD [1]

- Wirop [1]

- Wisent [1]

- WISSNER [3]

- WIWA [1]

- WM WORKS [1]

- WMT [201]

- WMTR [1]

- WMW [32]

- WMW GOTHA [1]

- WMW ZERBST [1]

- WMW - WILDAU [1]

- WMW Aschersleben [3]

- WMW GLAUCHAU [1]

- WMW GOTHA [1]

- WMW Heckert [1]

- WMW MAGDEBURG [2]

- WMW NILES [7]

- WMW UNION [1]

- WMW ZERBST [1]

- WMW- NILES [3]

- WMW-ASCHERSLEBEN [1]

- WMW-BLEMA [1]

- WMW-GOTHA [1]

- WMW-HECKERT [10]

- WMW-MEUSELWITZ [1]

- WMW-MIKROMAT [2]

- WMW-MODUL [4]

- WMW-NILES [3]

- WMW-UNION [1]

- WMW-VEB [1]

- WMW-VEB PULSNITZ [1]

- WOELLNER [1]

- WOERNER [2]

- Woeste [1]

- WOHLENBERG [26]

- WOHLENBERG-LÖW [1]

- WOHLHAUPTER [3]

- WOKO [1]

- WOLFF, SOLINGEN [1]

- WOLPERT [2]

- WORKING PROCESS [2]

- Wortelboer [1]

- WOTAN [14]

- WRK [1]

- WSI [1]

- WTC [1]

- WTO,WNT,EWS [2]

- WUENSCH Systemat [1]

- WUHAN [1]

- WÜRTH [1]

- WÄLZTECHNIK [5]

- WÖRNER [3]

- Xerox [1]

- XYZ [3]

- YALE [5]

- YAM [1]

- YANG IRON WORKS [1]

- YASDA [1]

- YASKAWA [9]

- Yato [1]

- YCM [1]

- ycm SUPERMAX [3]

- Yoga [2]

- YOMIS [1]

- YOMIS - TSUNODA [1]

- YUNNAN [1]

- ZANI [1]

- Zanrosso [1]

- Zattoni [1]

- Zavody Tazkeho Strojarstva [1]

- ZAYER [17]

- ZEGA [1]

- ZEHNDER & SOMMER [3]

- ZEISS [9]

- Zentrierspitze [1]

- ZERBST [3]

- ZETT - MESS [1]

- ZETT-MESS [1]

- ZETTL [2]

- ZEULENRODA [10]

- ZIEHKISSEN [4]

- ZIEHL-ABEGG [1]

- ZIERSCH & BALTRUSCH [10]

- ZIMMER [35]

- ZIMMER SOMMER [9]

- Zimmer+Kreim [1]

- ZIMMERMANN [1]

- ZINSER [3]

- ZIONAIR [1]

- ZIROTEC [1]

- ZJ [2]

- ZMM [32]

- ZMM - SLIVEN [3]

- ZMM / HUVEMA [1]

- ZMM BULGARIEN [1]

- ZOLLER [18]

- ZOPF [19]

- ZPS [3]

- ZPS DEPO [1]

- ZUBEHOER [1]

- ZUCOR [1]

- ZWICK [2]

- Österreichisches Fabrikat [1]

- Traders

Showoffers:

- machine-categorie:

Machines available immediately

Machinelist: Machines available immediately

Double Wheel Grinding Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-1687383 · Double Wheel Grinding Machine

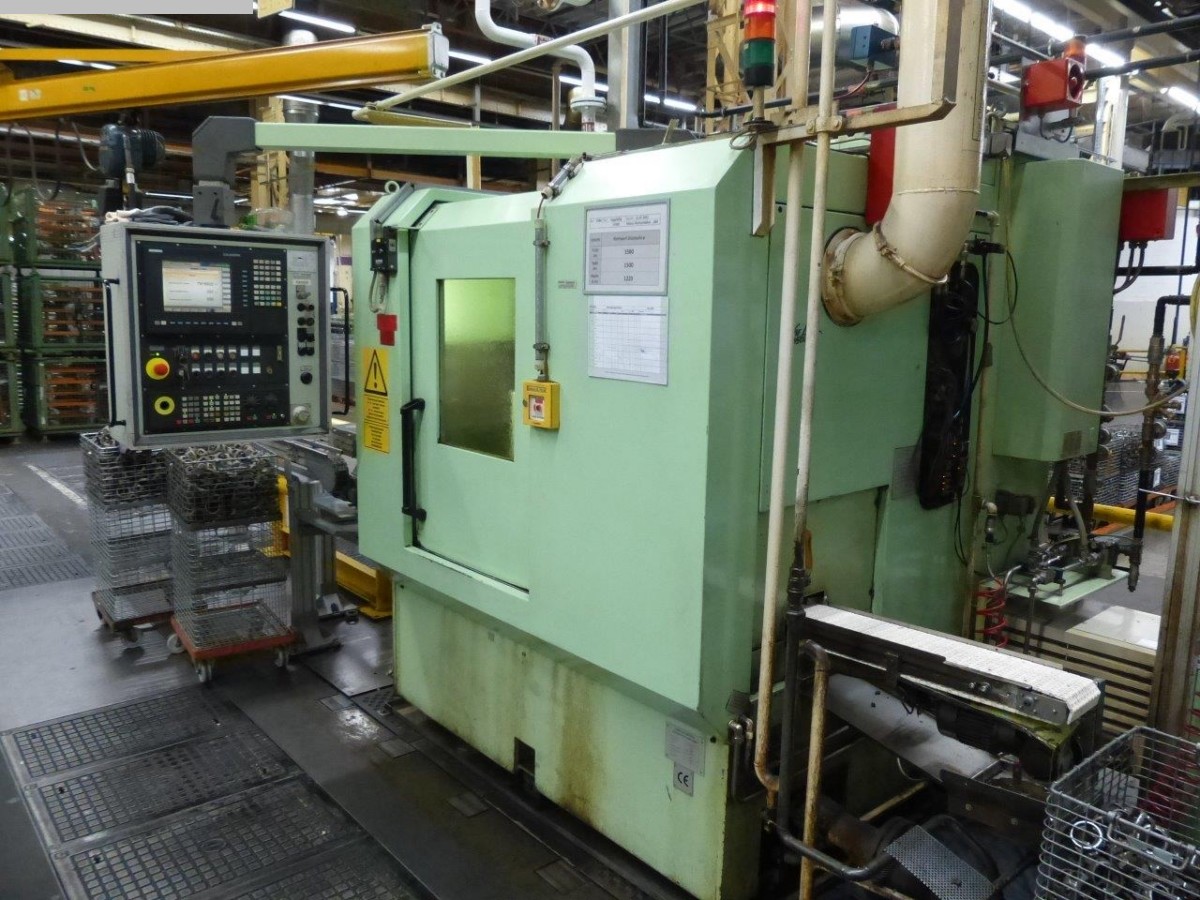

DISKUS - DDS 600 III PRM - CNC - - 1992 -

Technical details

D I S K U S (Germany) CNC Controlled Double Sided Vertical Spindle Surface Grinder with Rotary Workpiece Feed System and IONIC Size Control Model DDS 600 III PLM - CNC Year 1992 erial No. 7924 _______________________________________________________ Grinding wheel Ø x bore x height, each 600 x 150 x 75 mm Approximate Workpiece dimensions: Grinding height, approx. 1.5 – 50 mm Grinding width, appox. 20 - 120 mm Vertical quill adjustment, each, approx. 150 mm Infeed of grinding wheels via CNC 0.0001 mm Feed of workpiece transportation device, infinitely variable 40 – 235 mm/sec Grinding wheel speed, each (30 m/s) 191 - 955 rpm Grinding spindle drive, each infinitely variable 37 kW Total electrical load, approx. 85 kW - 380 V - 50 Hz Weight, approx. 9,500 kg Accessories / Special Features * SIEMENS CNC Control, Model SINUMERIK 810 G, with monitor, for 4 axes i.e. * Movement of 2 spindle quills, dressing device, WP Rotation. Direct programming of Grinding Process data on keyboard. In connection with a IONIC Size Control No. 17 A / 68.000 with two tracers for measuring the thickness of the workpieces after grinding process, and corresponding infeed of the grinding wheels. Continuous display of measuring results on the monitor, with statistics, workpiece counter, etc. Digital Display Ampere for both grinding wheel drives and for grinding spindle speeds, etc. . * Positioning control device for supervising the height of the lower grinding wheel.. * Double column design as a portal for extra stability and higher accuracy * Rotary workpiece transportation device with infinitely variable feeds. The workpieces are Manually stacked in a device and forwarded by a transportation carrier disk thru the grinding wheels, there are two WP- down holders, one equipped with a overheight stop-control. * Angled grinding wheel dressing device, with automatic dressing process, integrated in the control as CNC axis, with safety switch-off. * Separate large switch cabinet. * Automatic central lubrication. Large pneumatic control system * Large Coolant device 6 (F) with filtering unit and magnetic separator. * Various Grinding wheels, WP transport carrier disks, 2 flanges, large Olimist separator, etc. This machine is very suitable for simultaneous double-sided grinding of large series of workpieces, e.g. punched parts, piston rings, hydraulic parts, rotors, distance rings, etc. Condition : Very good. Machine can be soon inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

grinding height

50 mm

grinding width

120 mm

grinding wheel diameter

600 mm

total power requirement

85 kW

weight of the machine ca.

9500 kg

Description :

D I S K U S (Germany)CNC Controlled Double Sided Vertical Spindle Surface Grinder

with Rotary Workpiece Feed System and IONIC Size Control

Model DDS 600 III PLM - CNC Year 1992 erial No. 7924

_______________________________________________________

Grinding wheel Ø x bore x height, each 600 x 150 x 75 mm

Approximate Workpiece dimensions:

Grinding height, approx. 1.5 – 50 mm

Grinding width, appox. 20 - 120 mm

Vertical quill adjustment, each, approx. 150 mm

Infeed of grinding wheels via CNC 0.0001 mm

Feed of workpiece transportation device,

infinitely variable 40 – 235 mm/sec

Grinding wheel speed, each (30 m/s) 191 - 955 rpm

Grinding spindle drive, each infinitely variable 37 kW

Total electrical load, approx. 85 kW - 380 V - 50 Hz

Weight, approx. 9,500 kg

Accessories / Special Features

* SIEMENS CNC Control, Model SINUMERIK 810 G, with monitor, for 4 axes i.e.