Metal Processing

Machinelist: Metal Processing

lathe-conventional-electronic

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207356 · lathe-conventional-electronic

BERNARDO - JUNIOR 150 - - 2014 -

Technical details

** New price ~ 3.500 euros **Special price on request Furnishing: - very handy machine with lead and pull spindle - Ideal for the hobby sector - 3-jaw chuck 160 mm including replacement jaws + lathe chuck protection - fixed bezel - rotating bezel - Quadruple steel holder - chip tray - Splash wall - Bed made of gray cast iron, solid design - Bed guide inductively hardened and ground - Main spindle with Camlock D1-4 mount - Tailstock can be moved +/- 5 mm for taper turning - Spindle bearing with 2 adjustable precision bearings - Single lever clamping for the tailstock - Guides can be adjusted using wedge strips - Upper slide can be rotated +/- 45° - Machine base including side storage compartments - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207356

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207347 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - 1x collet chuck including collets (inserts) - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including insert - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207347

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207350 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including inserts - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207350 * Machinevideo : https://www.youtube.com/watch?v=ba6oQf-zdhs

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207349 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 V DIGITAL - - 2013 -

Technical details

** from a training workshop !! ** good condition - new price approx. 14.000 euros ** Special price on request Characteristics : - Standard with delta frequency converter - for high torque in the lower speed range . and almost constant speed under load - Infinitely variable speed control - The set speed is read via a digital display - Prism bed made of gray cast iron, induction hardened and precision ground - Central, handy switching for feeds and threads - with lead and pull spindle - Modern main spindle bearing with precision angular contact ball bearings - Standard with frequency converter and 3-axis position display - Hardened and ground gears and shafts, also in the feed gear - The speed and feed adjustment is simple - can be switched smoothly and precisely - Sliding tailstock for taper turning - Handwheel with adjustable fine scaling (0.02 mm) - The removable bridge - allows machining of large diameter workpieces Furnishing : - EASSON 3-axis digital display with LCD display - 1x 3-jaw steel chuck PO3-200 mm / D6 - 1x flat/clamping jaw chuck - 1x collet chuck including collets (inserts) - Fixed bezel - Passage diam. max. 135 mm - Revolving bezel - Passage diam. max. 65 mm - Foot pedal with braking function according to CE - MULTIFIX steel holder including insert - Protective device for steel holder - Revolver stop with fine adjustment (end stop) - electric frequency converter - Coolant device - Slip clutch - Machine light - Chip back wall - Machine swing feet - other accessories such as rotating center punch etc. - Operating instructions (DE) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207349

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207305 · lathe-conventional-electronic

ZMM / HUVEMA - HU 310 VAC - - 2004 -

Technical details

** New price ~ 23.000 euros ** from a training workshop (!!) Furnishing: - Spindle speed continuously adjustable in 2x switching stages - "TOS" 3-jaw lathe chuck Ø 160 mm, with spare jaws & chuck key - "NEWALL" digital display, front left - MULTIFIX steel holder with inserts - Movable tailstock - live center, incl. quick-action drill chuck - digital speed display - Change gears - Foot/spindle brake * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Spindle bore 32 mm - Turning diameter over cross slide 175 mm - bed width 200 mm - Spindle mount / DIN55027 5 - Spindle taper 4.5 M - Spindle speed infinitely variable in switching stages 2 - Spindle speed stepless 85-405; 470-2200 rpm - Number of feeds 48 - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 710 kg

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207330 · lathe-conventional-electronic

ZMM - SLIVEN - HU 310 - - 2002 -

Technical details

** New price ~ 20.000 euros ** from a technical college (!!) Furnishing: - Robust conventional center lathe - 3-jaw lathe chuck Ø 160 mm, with replacement jaws - "NEWALL" digital display, front left - MULTIFIX steel holder with 4x inserts - fixed bezel - moving bezel - Movable tailstock - Foot/spindle brake - Machine swing feet - User manual (PDF/NL) * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Turning diameter over support 175 mm - Spindle bore 32 mm - bed width 200 mm - Spindle mount / DIN 55027 GR 5 - Spindle taper 4.5 M - Spindle speed 85 - 2000 rpm. - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 770 kg * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207330 * Machinevideo : https://www.youtube.com/watch?v=iqU7Bkh6INo

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207346 · lathe-conventional-electronic

QUANTUM - D 460-1500 E - - 2000 -

Technical details

** Machine from a maintenance workshop ** current new price ~ 17.500 euros ** Special price on request Lathe with precision ground and induction hardened bed. Very suitable, for example, for use in workshops and teaching facilities. Furnishing: - robust lead and pull spindle lathe - RÖHM 3-jaw chuck, including replacement jaws & chuck key - foldable lathe chuck protection - MULTIFIX steel holder - size B - with 2x inserts - movable tailstock, with rotating center center - universally adjustable machine light - Chip protection back wall - EMERGENCY stop button at the front - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207346

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207331 · lathe-conventional-electronic

ZMM - SLIVEN - HU 310 - - 2000 -

Technical details

** New price ~ 20.000 euros ** from a technical college (!!) Furnishing: - Robust conventional center lathe - 3-jaw lathe chuck Ø 160 mm, with replacement jaws - "NEWALL" digital display, front left - MULTIFIX steel holder with 3x inserts - fixed bezel - moving bezel - Movable tailstock - Foot/spindle brake - Machine swing feet - User manual (PDF/NL) * all technical data: - Turning diameter over bed 310 mm - Distance between centers 750 mm - Turning diameter over support 175 mm - Spindle bore 32 mm - bed width 200 mm - Spindle mount / DIN 55027 GR 5 - Spindle taper 4.5 M - Spindle speed 85 - 2000 rpm. - Metric thread range 0.1 - 28 mm - Thread module range 0.1 - 1.75 - Thread DP range 4 - 70 - Adjustment range cross slide 150 mm - Adjustment range top slide 95 mm - Tailstock quill diameter 40 mm - Tailstock recording 3 MK - Tailstock quill travel 100 mm - Motor power 2.2 kW - Weight 770 kg * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207331

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207343 · lathe-conventional-electronic

COLCHESTER - TRIUMPH V/S 2500 - - 1995 -

Technical details

** from a training workshop ** good condition (!) The Colchester Triumph VS is the “all-rounder”. From the heavy cutting This precision machine corresponds to the fine precision finish Requirements from modern tool construction, form construction or training company. Furnishing: - 3 -cheezing - diameter 200 mm, with replacement cheeks - Multifix steel holder, with use - Continuous speed adjustment via electric potentiometer - digital speed display - sliding riding stock - feed key - Coolant pan - Not from button, front - Spanning back wall - User manual (PDF) * Maschinenlink: http://mhp.logotech.de/hpm/v7/datenblatt/datenblatt.php?machineno=1008-9207343

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207353 · lathe-conventional-electronic

EMCO - MAT-17D - - 1995 -

Technical details

** Machine from a vocational school (NL) ** very well-maintained condition (!!) Furnishing: - robust lead and pull spindle lathe - Guideways, gears and quill hardened and ground - Electromechanical spindle brake - Diagonally ribbed, induction hardened machine bed - Infinitely variable speed control/constant cutting speed - digital speed display - EMCO digital display - mounted on the bed carriage - EMCO 3-jaw chuck Ø 200 mm - RÖHM 4-jaw chuck Ø 250 mm - foldable lathe chuck protection - Steel holder with 2x inserts - fixed bezel - movable tailstock, with rotating center point - removable chip tray - Chip protection back wall - Coolant device - Bed stop - EMERGENCY stop button (on digital display) - rigid lead and pull spindle cover - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207353

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207354 · lathe-conventional-electronic

EMCO - MAT-17D - - 1995 -

Technical details

** Machine from a vocational school (NL) ** very well-maintained condition (!!) Furnishing: - robust lead and pull spindle lathe - Guideways, gears and quill hardened and ground - Electromechanical spindle brake - Diagonally ribbed, induction hardened machine bed - Infinitely variable speed control/constant cutting speed - digital speed display - EMCO digital display - mounted on the bed carriage - EMCO 3-jaw chuck Ø 200 mm - RÖHM 4-jaw chuck Ø 250 mm - foldable lathe chuck protection - Steel holder with 2x inserts - fixed bezel - movable tailstock, with rotating center point - removable chip tray - Chip protection back wall - Coolant device - Bed stop - EMERGENCY stop button (on digital display) - rigid lead and pull spindle cover - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207354

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207335 · lathe-conventional-electronic

WEILER - COMMODOR - - 1989 -

Technical details

** Machine from a workshop for the disabled Lathe with precision ground and induction hardened bed. Very suitable e.g. for use in workshops and training centres. Furnishing: - Robust main lathe and spindle lathe with VARIO gear - 2 axis "HEIDENHAIN" digital display, front left - FORKARDT 3-jaw chuck Ø 200 mm, with spare jaws & chuck key - foldable lathe chuck protection - MULTIFIX steel holder - size B - with 5x inserts - Movable tailstock, with live center - Chip protection rear panel - 4x machine swing feet - 2x EMERGENCY OFF button on the front - Lead/feed screw protection - adjustable bed stop - Various application / turning tools * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207335

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207319 · lathe-conventional-electronic

VEB MIKROMAT - DLZ 315x500/3eG - - 1985 / 2013 -

Technical details

** Refurbished and repainted in 2013 ** Costs around 16.000 euros Furnishing: - WNW NILES 3-jaw chuck Ø 200 mm - Multifix steel holder size B with inserts - revolving center points - chuck key - Movable tailstock - Operation manual

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207352 · lathe-conventional-electronic

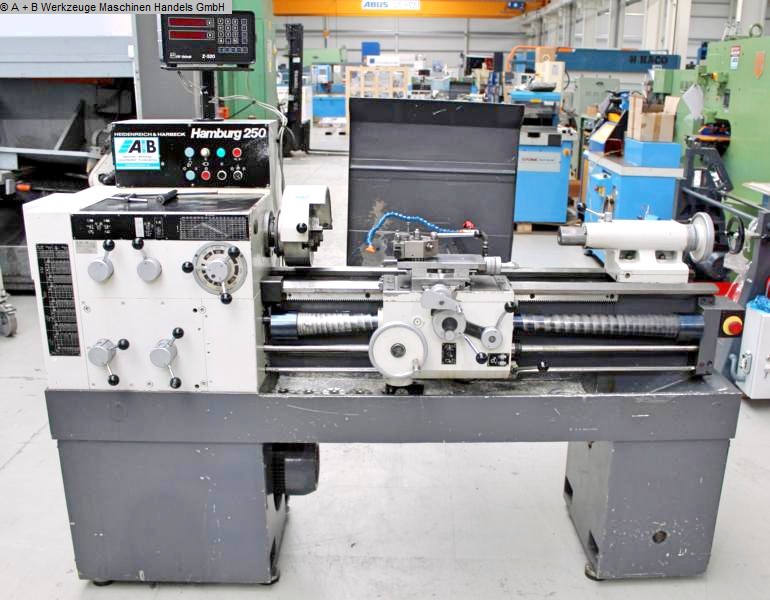

HEIDENREICH & HARBECK - HAMBURG 250 - - 1982 -

Technical details

** Machine from a vocational school (NL) Lathe with precision ground and induction hardened bed. Very suitable, for example, for use in workshops and teaching facilities. Furnishing: - robust lead and pull spindle lathe - RSF "Z-520" 2-axis digital display - RÖHM 3-jaw chuck Ø 200 mm, including chuck key - foldable lathe chuck protection - DREHBLITZ steel holder - TYPE DB 70 - with 2x inserts - robust, movable tailstock including center point - Chip protection back wall - 4x machine swing feet - 1x thread clock - Lead and pull spindle protection - Coolant device - EMERGENCY stop button on the front right - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207352

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9207351 · lathe-conventional-electronic

HEIDENREICH & HARBECK - HAMBURG 250 - - 1982 -

Technical details

** Machine from a vocational school (NL) Lathe with precision ground and induction hardened bed. Very suitable, for example, for use in workshops and teaching facilities. Furnishing: - robust lead and pull spindle lathe - RSF "Z-520" 2-axis digital display - RÖHM 3-jaw chuck Ø 200 mm, including chuck key - foldable lathe chuck protection - DREHBLITZ steel holder - TYPE DB 70 - with 2x inserts - robust, movable tailstock including center point - Chip protection back wall - 4x machine swing feet - 1x thread clock - Lead and pull spindle protection - Coolant device - EMERGENCY stop button on the front right - User manual (PDF) * Machine link: http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207351

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

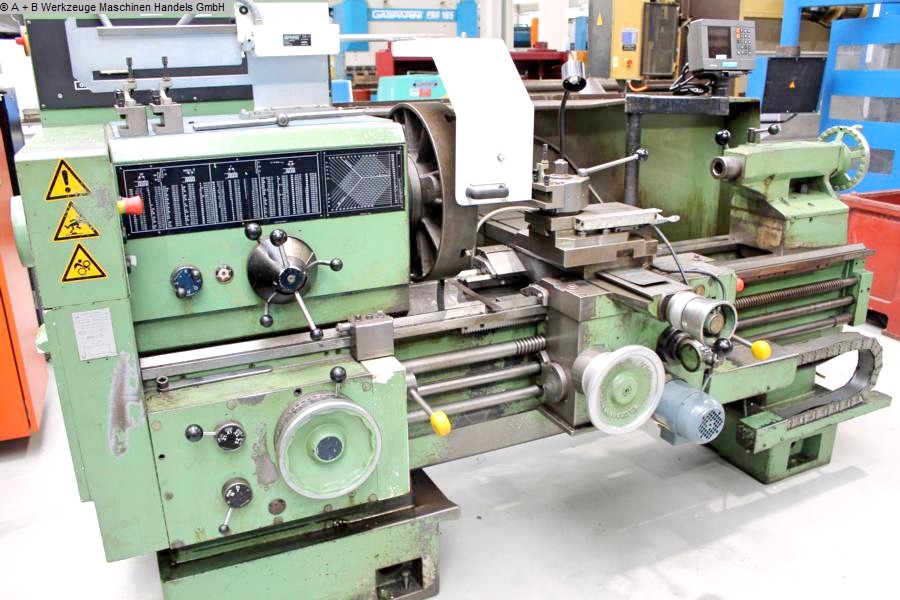

#1008-9207337 · lathe-conventional-electronic

VDF HEIDENREICH & HARBECK - HANSEAT 640 - - 1978 -

Technical details

** from a maintenance workshop - good condition (!!) ** Machine was checked annually Furnishing: - heavy - robust lead/pull spindle machine - "WERNER GARANT" face plate Ø 500 mm - HEIDENHAIN digital display - type ND 730 - MULTIFIX steel holder, with 3x inserts - "FINN SAFETY" lining protection - type SPS 600 - movable tailstock - Machine light - 1x food key - Chip back wall - movable bed stop - 2x EMERGENCY STOP switches - Coolant system, with collecting tray * Machine link: https://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9207337

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

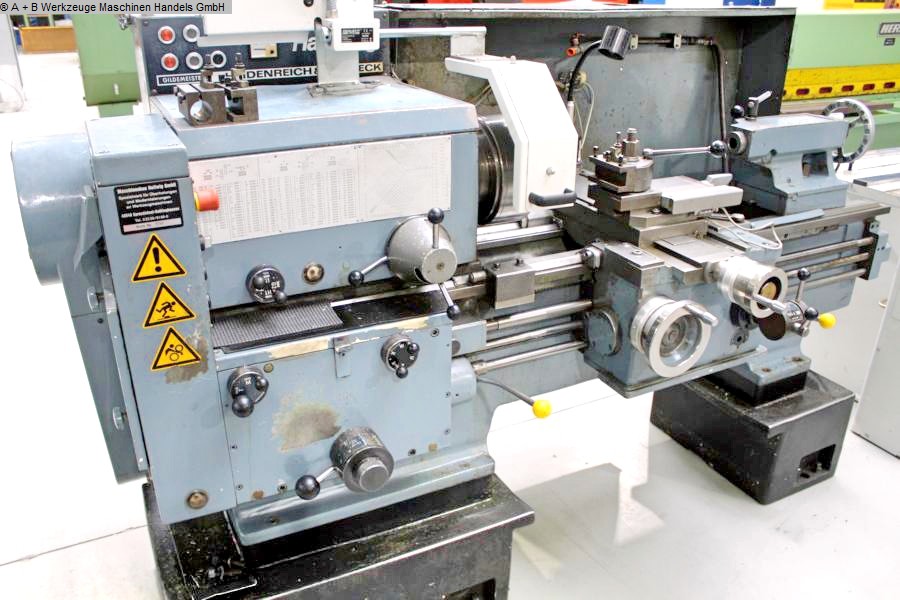

#1008-9207336 · lathe-conventional-electronic

VDF HEIDENREICH & HARBECK - HAMBURG 430 - - 1975 -

Technical details

** from a workshop for the disabled (!!) Furnishing: - robust master/feed spindle machine - FORKARDT 3-jaw chuck Ø 200 mm (DIN 55027 size 6) - HEIDENHAIN digital display - MULTIFIX steel holder, with insert - Movable tailstock - chuck key - chip rear wall - sliding bed stop - Protection for bed rails - live center - Coolant device, with drip tray

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203008 · lathe-conventional-electronic

BERNARDO - SMART 410-1000 Digital - - -

Technical details

Furnishing : - 3-axis digital display ES-12 V with LCD display - 3-jaw chuck DK11-200 mm / D6 - clamping disc 350 mm - Fixed bezel - passage diam. max. 135 mm - Revolving steady rest - passage diam. max. 65 mm - coolant device - Quadruple steel holder - Protective device with quadruple steel holder - Micrometer longitudinal stop - slip clutch - Revolver stop with fine adjustment - Thread clock - Motor with magnetic brake according to CE standard - Foot pedal with brake function according to CE - First filling with Shell Tellus 46 - LED machine light - change gears - reducing sleeve - 2 center points - Chip back wall - Operating tool

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203115 · lathe-conventional-electronic

BERNARDO - TITAN 560-2000 PRO - - -

Technical details

Furnishing : - 3-axis digital display ES-12 V with LCD display - 3-jaw chuck PS3-315 mm / D8 - clamping disc 450 mm - Fixed bezel - passage diam. max. 180 mm - Live steady rest - passage diam. max. 120 mm - 2 center points - First filling with Shell Tellus 46 - Motor with magnetic brake according to CE standard - Foot pedal with brake function according to CE - coolant device - Quick change tool holder with 4 inserts - Protective device for quick-change tool holders - slip clutch - LED machine light - change gears - reducing sleeve - Chip back wall - operating tool

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203159 · lathe-conventional-electronic

BERNARDO - SOLID 460-1500 DIGI PRO - - -

Technical details

Description: The Solid 460 Pro universal lathe was specifically designed to be economical Manufacture of individual workpieces and small series with high precision designed. Even the basic equipment includes all the important ones Accessories, which make this machine universally applicable. Scope of delivery : - 3-axis digital display ES-12 V with LCD display - 3-jaw chuck PS3-250 mm / D8 - Clamping disk 450 mm - Coolant device - Initial filling with Shell Tellus 46 - Fixed bezel - Passage diam. max. 150mm - Revolving bezel - Passage diam. max. 110mm - Quick-change tool holder with 4 inserts - Protective device for quick-change tool holder - Motor with magnetic brake according to CE standards - Foot pedal with braking function according to CE - Slip clutch - Rapid traverse longitudinally and flatly - Interchangeable wheels - 2 centering points - reducing sleeve - Thread clock - LED machine light - Chip back wall - Operating tool

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203096 · lathe-conventional-electronic

BERNARDO - MASTER PRO 360 - - -

Technical details

scope of delivery : - 3-axis digital display i200 with LCD display - 3-jaw chuck DK11-200 mm / D5 - Face plate 200 mm / D5, according to DIN 55029 - Fixed bezel - passage diam. max. 70 mm - Live steady rest - passage diam. max. 60 mm - coolant device - First filling with Shell Tellus 46 - Pull-out chip tray - clamping disc 280 mm - Quadruple steel holder - Protective device with quadruple steel holder - slip clutch - Longitudinal micrometer stop - Thread clock - LED machine light - reducing sleeve - change gears - 2 center points - Foot pedal with brake function according to CE - Motor with magnetic brake according to CE standard - Base with drawers - operating tool

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203117 · lathe-conventional-electronic

BERNARDO - MASTER 380-1000 Digital - - -

Technical details

Furnishing : - 3-axis digital display i200 with LCD display - 3-jaw chuck DK11-200 mm / D5 - Face plate 200 mm / D5, according to DIN 55029 - Fixed bezel - passage diam. max. 70 mm - Live steady rest - passage diam. max. 50 mm - coolant device - First filling with Shell Tellus 46 - Pull-out chip tray - clamping disc 320 mm - Quadruple steel holder - Protective device with quadruple steel holder - slip clutch - Longitudinal micrometer stop - Thread clock - LED machine light - reducing sleeve - change gears - 2 center points - Foot pedal with brake function according to CE - Motor with magnetic brake according to CE standard - Base with drawers - operating tool Special accessories included in the price: - 3-axis digital display

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203100 · lathe-conventional-electronic

BERNARDO - TITAN 660-3000 Digital - - -

Technical details

scope of delivery : - 3-axis digital display ES-12 V with LCD display - slip clutch - Rapid traverse lengthways and flat - LED machine light - 3-jaw steel chuck PO3-315 mm / D8 - clamping disc 450 mm - Fixed bezel - passage diam. max. 180 mm - Live steady rest - passage diam. max. 120 mm - 2 center points - Motor with magnetic brake according to CE standard - Foot pedal with brake function according to CE - First filling with Shell Tellus 46 - coolant device - Quick change tool holder with 4 inserts - Protective device for quick-change tool holders - change gears - reducing sleeve - Chip back wall - Cable routing via energy chain - operating tool

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-8203140 · lathe-conventional-electronic

BERNARDO - Standard 165 V-D - - -

Technical details

Scope of delivery: - 3-axis digital display i200 with LCD display - 3-jaw chuck DK11-160 mm / D4 - Face plate 200 mm / D4, according to DIN 55029 - Fixed bezel - passage diam. max. 60 mm - Live steady rest - passage diam. max. 60 mm - clamping disc 250 mm - Quadruple steel holder - Shaft fixing device - Protective device at steel holder - slip clutch - Longitudinal micrometer stop - coolant device - Pull-out chip tray - Frequency converter - Foot pedal with brake function according to CE - bulkhead - Thread clock - LED machine light - Digital speed display - reducing sleeve - change gears - 2 center points - underframe - operating tool

Профіль торговця: A + B Werkzeuge Maschinen Handels GmbH

Зв'язатися з трейдером

Ротвег 17

48683 - Ахаус

Німеччина

(0049)-2561-9384-71">(0049)-2561-9384-71

(0049)-2561-9384-36

info@ab-maschinen.de

www.ab-maschinen.de

Профіль Трейдера

Metalworking comprises a variety of applications involving the manipulation of metal from large-scale production of metals including lathing milling and cutting to smaller operations such as jewellery working. No matter the application used metal processing machines present an ideal way of obtaining the equipment you need at a price you can afford. Used metal processing machines such as milling machines can be manually operated or using computer numeric control which increases the overall precision of the machine. The type of used metal processing machines you need depends on the applications you use but at LagerMaschinen.de you are sure to find what you’re looking for.

The right machine for every field of applicationUsed metal processing machines can be used in several fields. Companies active in the computer industry can obtain used metal processing machines for circuit board soldering and companies that need to bond different pieces can find the welding machines that they need. If your company is in the business of making the precision parts needed to make other precision machines then used grinding machines can be a great way to expand or refurbish your production lines. Used metal processing machines can also be found for lathing drilling milling and several other uses.

Used equipment from LagerMaschinen.deNo matter the type of equipment you will find the used metal processing machines you need at LagerMaschinen.de. With its international network of suppliers this platform can provide you with the used metal processing machines you need at a price you can afford.

Rottweg 17

Contact Trader

Rottweg 17

48683 - Ahaus

Deutschland

(0049)-2561-9384-71

(0049)-2561-9384-36

info@ab-maschinen.de

www.ab-maschinen.de

Contact person:

* über 500 Maschinen lagernd -

Gerne führen wir Ihnen Ihre gewünschte Maschine unter Strom vor *