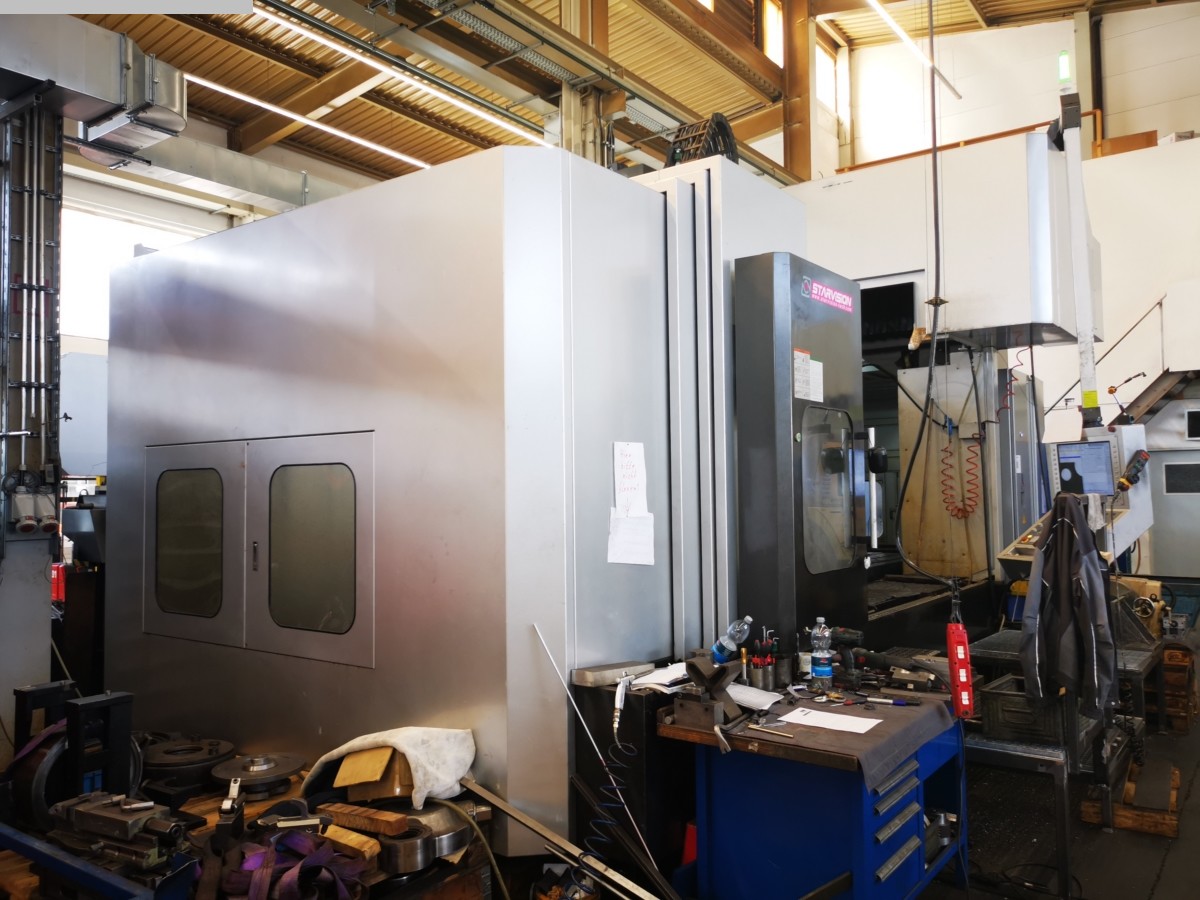

Portal - Machining Center

Machinelist: Portal - Machining Center

Portal - Machining Center

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06241 · Portal - Machining Center

Starvision - - - 2019 - Heidenhain iTNC 640

Technical details

Technical data: Travel paths Longitudinal travel / X-axis 3200 mm Cross travel / Y-axis 3400 mm Vertical travel / Z-axis 1200 mm Table clamping area 3000 x 2400 mm T-slots 13 x 28 x 180 mm Max. table load 11000 kg Spindle Motor power S1/S6-60%/S6-25% 32/43/53 kW Max. torque S1/S6-60%/S6-25% 819/1100/1356 Nm Spindle holder BTT 50-BIG PLUS Max. spindle speed continuously 6000 1/min. 2-stage gear drive / HAMADI KOKI - Japan Distance spindle nose - milling table 350 - 1550 mm Distance between stands 2800 mm Feeds Max. working feed 7000 mm/min. Rapid traverse X/Y 12000 / Z 15000 mm/min. General information Installation area with chip conveyor 10833 x 6680 mm Height 5702mm Net weight of the machine with accessories 40000 kg Standard equipment: CNC path control Heidenhain iTNC 640 Linear scales from Heidenhain in all X, Y and Z axes Axis motors from Heidenhain Spindle motor from Heidenhain Electronic handwheel from Heidenhain HR-510 Machine in a stable cast design Linear guides from Schneeberger, size 55 in the X axis, size 65 in the Z/Y axis Spindle oil cooler Coolant tank Complete coolant system Chip flushing pump Synchronized tapping/spindle orientation High precision ball screws grade C3 Double arm gripper tool changer 60 times Air blast to clean the spindle cone when changing tools Hydraulic tool clamping system Hydraulic weight compensation in the Z axis - double cylinder Automatic central lubrication Electric cabinet with air conditioning Full machine cladding with two sliding doors for easy machine access Twin screw chip conveyor (longitudinal) and hinged belt (transverse) Low voltage machine light and work status light RS 232 C, USB, Ethernet communication system and TELESERVICE Installation elements CE safety standards Including the following special accessories/options: Spindle motor from Heidenhain QAN 320 M (instead of QAN 260 UH) IKZ cooling through the spindle 20 bar with Grundfos high-performance pump with microfilter Air cooling through the spindle via M function Flush gun Preparation for electronic dividing head, 4-axis "AC-2" Automatic universal swivel head / max. speed 3000 1/min. A and B axes each indexable by 5° - 72x72 positions Automatic tool changing and IKZ cooling through the spindle 20 bar Spindle holder BT 50 Automatic PICK UP for milling head rollers - 2 stations Y-axis extension at 800 mm (400 mm per side) Y-axis travel 3400 mm Chain tool changer 60-fold vertically changing Renishaw RMP-60 measuring probe for workpiece setup and testing Measuring probe cycles for Heidenhain TNC 640 installed

Datasheet

Request / Contact

Профіль торговця: Knops Werkzeugmaschinen

GmbH & Co. KG

Зв'язатися з трейдером

Кружки Веркезугмашінена

GmbH & Co. KG

Конрад-Цузе-штрассе, 5

40789 - Монхайм

Німеччина

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

GmbH & Co. KG

Конрад-Цузе-штрассе, 5

40789 - Монхайм

Німеччина

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Профіль Трейдера

TOP Manufacturer:

STARVISION - WELE - WALDRICH-COBURG -

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

Contact Trader

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Machine category

4-Säulenpresse - Hydraulisch · Abkantpresse - hydraulisch · Aufspanntisch · Aufspannwinkel · Bandsägeautomat - Horizontal · Bearbeitungszentrum - Horizontal · Bearbeitungszentrum - Universal · Bearbeitungszentrum - Vertikal · Blechrundbiegemaschine - 3 Walzen · Blechrundbiegemaschine - 4 Walzen · Brennschneidemaschine · CNC Dreh- und Fräszentrum · Doppelständerpresse - Hydraulisch · Drehbarer Aufspanntisch · Drehmaschine - zyklengesteuert · Fahrständerfräsmaschine · Fixatoren · Flachschleifmaschine - Doppelständer · Flachschleifmaschine - Horizontal · Flachschleifmaschine - Vertikal · Fräseinrichtung · Innenschleifmaschine · Karusselldrehmaschine - Doppelständer · Koordinatenmessmaschine · Kühlmittelanlage · Lagertechnik · Leit- und Zugspindeldrehmaschine · Magnetspannplatte · Messmaschine · Plan- und Spitzendrehbank · Planscheibe · Portal - Bearbeitungszentrum · Portalfräsmaschine · Roboter - Handling · Rundschleifmaschine - Außen · Rundtaktmaschine · Rundtisch · Rundtischflachschleifmaschine - 2 Spind. · Schleifmaschinenzubehör · Schweißdrehtisch - rund · Schwerdrehmaschine · Senkerodiermaschine · Stangenlademagazin · Tafelschere - hydraulisch · Tieflochbohrmaschine · Werkzeug Voreinstellgerät · Werkzeugfräsmaschine - Universal · Werkzeughalter · Werkzeugschleifmaschine - Universal · Zahnrad-Abwälzfräsmaschine - vertikal · Zahnradschleifmaschine · Zubehör · Ölnebel-Abscheider ·