Sheet metal working - shaeres - bending

Machinelist: Sheet metal working / shaeres / bending

Folding Machine

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08028 · Folding Machine

KAPEMA - KFS 20/20 - - Fabrikneu / new -

Technical details

Segmented top rail for bending box profiles, upper beam clamping hand-operated, manual bending beam actuation with weight compensation, degreescale, adjustable bend stop. Warranty = 12 months for single-shift operation. The bending performance refers to 380 N/mm² strength. Warranty = 12 months for single-layer operation. Warranty = 12 months for single-shift operation, this only covers spare parts the defective parts must be returned. The working time costs for The replacement is not covered, nor are the downtimes Machine. Machine dealer with own stock of 1600 m².

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08413 · Folding Machine

KAPEMA - KFS 10/25 - - fabrikneu -

Technical details

Sengmentable upper rail, upper clamping foot-operated, manual bending clamping operate. The bending performance refers to 380 N/mm² strength. Machine dealer with own stock of 1600 m².

Plate Shear - Mechanical

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

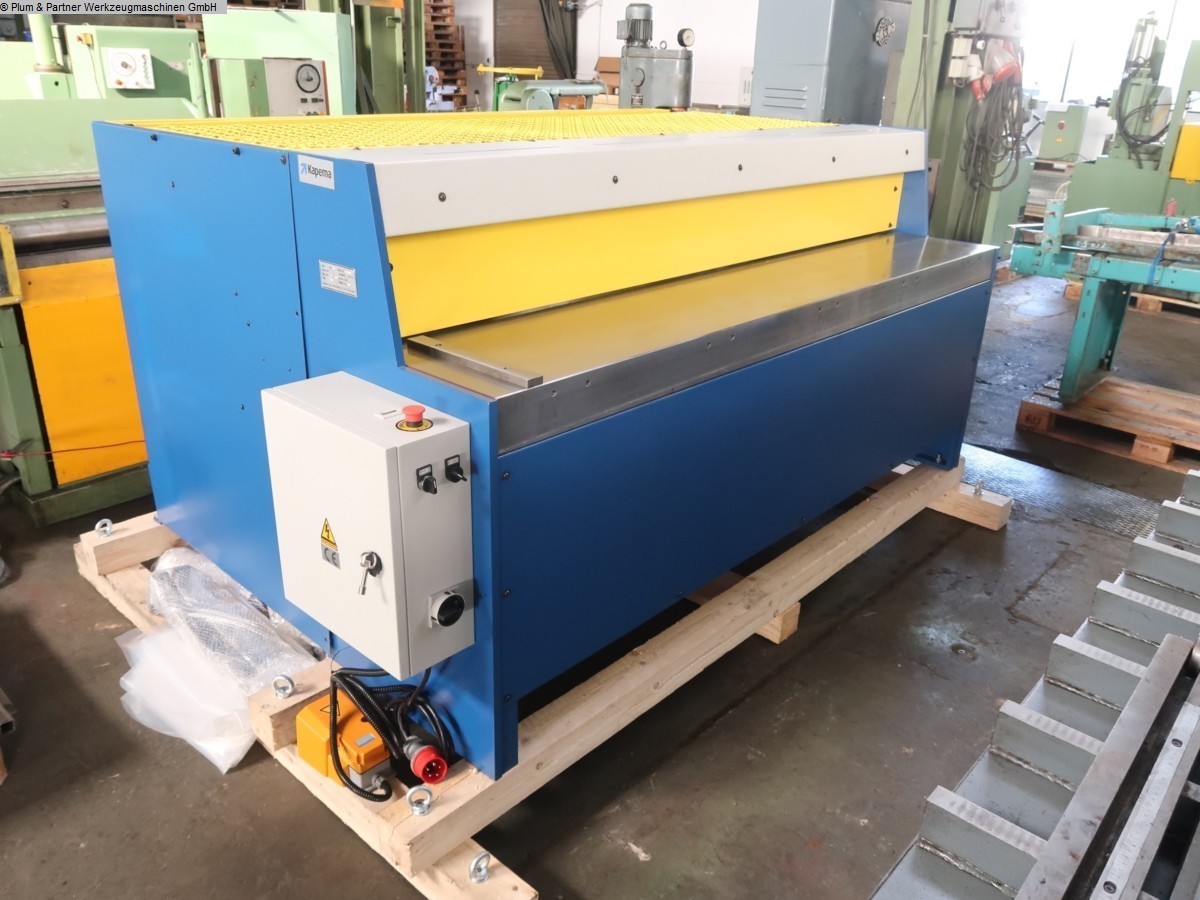

#1082-08037 · Plate Shear - Mechanical

KAPEMA - SMP 20-20 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08408 · Plate Shear - Mechanical

KAPEMA - SMP 12-30 - - Fabrikneu / new -

Technical details

The guillotine shears type SMP is a well-dimensioned machine with all-welded gate guides. The drive takes place with a standard geared brake motor via a chain connection to the main axis. The knives are of the highest quality. The optimal cutting angle ensures together with the rubber-coated sheet metal holder, perfect cuts. Bearings and guides are maintenance-free and lubrication-free. Standard equipment: • Back gauge 635 with mm scale. • Cutting line lighting. • Section counter. • Table extensions 600 mm. • Right-angled stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • rear photocell. Pre-freight to our stock + packaging 270, -. Machine dealer with own stock of 1600 m².

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-08417 · Plate Shear - Mechanical

KAPEMA - SMP 20-30 - - Fabrikneu / new -

Technical details

The new motor guillotine type SMP is a well dimensioned machine with all-welded link guides. The drive takes place with a Standard geared brake motor via a chain connection to the main axle. the Knives are of the highest quality. The optimal cutting angle secures the Together with the rubber-covered blank holder perfect cuts. Bearings and guides are maintenance and lubrication-free. Standard equipment: • Back gauge 665 with mm scale. • cutting edge lighting. • Section counter. • Table extensions 600 mm. • Right angle stop, left. • Movable 24 V foot switch with emergency stop. • Motor protection switch and emergency stop. • 2 cutting edges per knife. • Rear protective grille, warranty = 12 months for single-shift operation. Other models: 1275 x 3mm, 1250 x 4mm, 2050 x 2mm Machine dealer with own stock of 1600 m².

Turnstile

- SCHMITT REINHOLD GMBH

- Obernahmerstr. 74

- 58119 Hagen-Hohenlimburg

- Deutschland

-

+49 (0)2334 4847

+49 (0)2334 4840 -

info@reinhold-schmitt.de

www.reinhold-schmitt.de

#2008-0394 · Turnstile

AKV - - - -

Technical details

TURNSTILE 4-arms arm length (support seating) 500 mm capacity – each arm 2,00 to. dimension – floor - bottom edge arm app. 960 / 1.360 mm dimension – floor - upper edge arm app. 1.140 / 1.540 mm dimension – C-hook space (h x w) app. 80 / 180 x 80 mm wall thickness – arm app. 40 mm complete length app. 2.180 mm accessories: construction 4-arms turnstile mounted on base frame construction and equipped with 4 rotor wheels movement hydraulically – oil motor and chain rotor wheel diameter(outside) app. 260 mm rotor wheel diameter(inside) app. 240 mm gauge exactness app. 50 / 52 mm wheelbase – middle / middle – wheel app. 1.250 mm rotation process hydraulically – oil motor interlocking process hydraulically – bolt height adjustmnent hydraulically – cylinder / lifting height app. 110 mm valve stanbd mounted at frame construction energy chain (cable transport) mounted at frame construction no. – limting frame 1 x each arm hydraulic unit not available

Sheet metal working machines are machines used in the metalworking process involved in the production of sheet metal. Some of the types of used sheet metal working machines involved in this process are lathes roll slitters brake presses and stamping presses to name just a few. These used sheet metal working machines are used to cut bend flatten and otherwise manipulate metal into the desired shape and thickness. Used sheet metal working machines can be used to roll or bend sheet metal into a desired shape and to give the fold or curve the desired angle they can also be used to punch the sheet metal into the desired shape.

Used sheet metal working machines for every applicationFrom small home production labs for hobbyists to large-scale production facilities LagerMaschinen.de has used sheet metal working machines for every use. For some precision is not necessarily the most important consideration when choosing used sheet metal working machines. For others the precision and the flexibility of the used sheet metal working machines is the most important consideration. Whether you need bending folding cutting pressing or punching machines you will find what you are looking for at LagerMaschinen.de

Quality used machines at LagerMaschinen.deFor many companies the cost of new equipment can be a source of problems. With its international network of suppliers LagerMaschinen.de ensures that your used sheet metal working machines meet your quality requirements and at the same time guarantees a price that is far more cost-effective than new machines.

TOP Manufacturer:

OSTAS - TRUMPF - HESSE BY DURMA - ERMAK - DURMA - FASTI - NN - EHT - ASSISTMACH - HUVEMA -