coil line

Machinelist: coil line

coil line

- Ambold Pressen GmbH

- Sommeritzer Straße 43

- 04626 Schmölln

- Deutschland

-

+49 (0)3449183314

+49 (0)3449123492 -

info@ambold-pressen.de

www.ambold-pressen.de

#1010-531 · coil line

1SCHLEICHER/GSW - - - unbekannt -

Technical details

CNC roll feed, Make GSW, Type WVE 400/160 - weight 50/80 kg Straightener, 7 rolls, Make. Schleicher, Type RM 6-95/160 - band width 300 mm - band thickness 2 – 4 mm - cross cut 1200 mm² - voltage 220/380 V 50 Hz - total power requirement 3,1 kW coiler with press roll, Make Schleicher, Type H-3 - Coil weight 3 t - Band width 400 mm - voltage 220/380 V 50 Hz - total power requirement 3,92 kW

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-103046 · coil line

GSW - SHR 5000 / VCRL 650 - - 2000 - konventionell

Technical details

Feeder-straightening machine VCRL 650 (year of manufacture1994 / overhauled 2001) with infinitely variable drive, motoric height adjustment, hydraulic alligator opening, intermittent lifting Decoiler SHR 5000 (year of manufacture 2000) with hydraulic expansion, snubber roll

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-083096 · coil line

DREHER - 2352 B-FPS / SC 12-FQ - - 1997 - Siemens S 5

Technical details

Universal straightening machine SC 12-FQ with infinitely variable drive double decoiler 2352 B-FPS WITHOUT drive, with hydraulic expansion, pneumatic lag brake electronic roll feed WAV-RDS-2Z, modell 1082 B with AC-Servomotor, pneumatic intermediate lifting of the rolls

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-194014V · coil line

HENSEL - BRMS 4/500/10 / BSH 3-500 / - - 1996 - konventionell

Technical details

Straightening machine HENSEL BRMS 4/500/10 with infinitely variable drive Decoiler HENSEL BSH 3-500 mith motor for fix speed, auxiliary drive (declutchable), pneumatic snubber roll Electronic roll feed HENSEL EVX 500 with hydraulic intermediate lifting of the rolls Material thickness of feeder approx. 0,2 - 5,0 mm with coil loop control via light guard

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1740 · coil line

DREHER - 1676 AV-RA2 / 2370 B - - 1995 -

Technical details

Coil turner 2370 B Load capacity 1.5 ton. Bandwidth 300 mm Coil inner diameter: 400 - 500 mm Arm length per arm: 670 mm Dimensions: depth 1,230 mm, housing height 1,100 mm, width 1,700 mm Weight: 760 kg. Straightener Dreher 1676 AV-RA2 Material width: 200 mm Material thickness: 08 - 4.2 mm Number of straightening rollers: 7 Number of pull rollers: 4 Straightening rollers diameter: 80 mm Would be down by a running press Documents circuit diagrams, operating instructions etc. available

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-233027 · coil line

KOHLER / WEINGARTEN - 50.650/9-7500.1 / WEP 65 - - 1995 - konventionell

Technical details

Straightening machine KOHLER 50.650/9 with infinitely variable drive, driven straightening rolls, hardchromium-plated rolls, motoric adjustment of the roller cassette Decoiler KOHLER 7500.1 with auxiliary drive, hydraulic centralized expansion, hydraulic snubber roll, attachment jaws for expansion of the inner diameter to approx. 580 - 630 mm, motoric lateral movement, hydraulic lifting table Servo roll feed WEINGARTEN WEP 65 coil loop control via light guard

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-163021A · coil line

NORMATIC - DY 500 X3000 - - 1994 - konventionell

Technical details

Straightening machine RYD 40 x 500 hydraulic inlet guide Decoiler DY 500 x 3000 with hydraulic expansion, hydraulic coil lifting device elektronic roll feed AESL 500-2,8 can be offered without or with putting into operation in given condition

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-183063A · coil line

DREHER - 1676 E/RDS / 2380 FM-FPS - - 1994 - konventionell

Technical details

Feeder-straightening machine DREHER 1676 E/RDS Modell 1529/4 with infinitely variable drive Decoiler DREHER 2380 FM-FPS Modell 891/5 motoric driven. with pneumatic lag brake, manual centralized expansion, pneumatic snubber roll coil loop control Ultrasonic

- Maschinen Schwartpaul GmbH

- Am Wasserwerk 1

- 58840 Plettenberg

- Deutschland

-

+49 (0)2391-95960

+49 (0)2391-959620 -

info@maschinen-schwartpaul.de

www.maschinen-schwartpaul.de

#2020-15596 · coil line

TEAP - AMDC150+RM - - 1993 -

Technical details

Datasheet

Request / Contact

- VÖGTLE SERVICE GMBH

- Friedhofstr. 115

- 73054 Eislingen

- Deutschland

-

+49 71 61 99 73- 0

+49 71 61 99 73- 13 -

Thomas.Ruckh@voegtle.de

www.voegtle.de

#1050-133013 · coil line

DIMECO - 1676 EV / 2382 FFPS - - 1990 - konventionell

Technical details

Straightening machine Dimeco, 1676 EV with inlet table andpre-shaping roll, hydraulic loading bridge Double decoiler Dimeco 2382 FFPS with pneumatic lag brake, hydraulic expansion, hydraulic snubber roll, coil loading device elektronic roll feed Microfeed kann ohne in Betrieb nehmen oder alternativ mit neuer Steuerung Siemens S 7-1500 F angeboten werden can only be offered without putting into operation - video at seller's site before dismantling available

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03639 · coil line

SCHLEICHER - - - -

Technical details

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-739033 · coil line

SCHARF WESTFALIA - - - -

Technical details

Technical description : Blank Pallet Turnover Device / Blank Handlling (needs retrofit)

Datasheet

Request / Contact

Cut-to-length-lines

- SCHMITT REINHOLD GMBH

- Obernahmerstr. 74

- 58119 Hagen-Hohenlimburg

- Deutschland

-

+49 (0)2334 4847

+49 (0)2334 4840 -

info@reinhold-schmitt.de

www.reinhold-schmitt.de

#2008-056810 · Cut-to-length-lines

VIGANO/RIVA - - - 2000/2001 -

Technical details

sheet length 580 - 6.000 mm working direction left - right otherwise according to technical specification 05.68-1.0

Datasheet

Request / Contact

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19439 · Cut-to-length-lines

HITACHI - - - 1993 -

Technical details

Stainless steel Cut to Length Line(Flying type) - Material: stainless steel, surface treated steel -- Thickness: 0.3–3 mm (as of stainless steel) -- Width: 500-1350 mm -- Trim: 5-25 mm on one side (more than twice the plate thickness) - Material coil: internal diameter 508 mm, external diameter 600–1800 mm -- weight maximum 15 tons -- Width accuracy: 500–1350 mm plus or minus 0.2 mm (when side trimming) -- Product length: 400–6000 mm Plus/minus 0.3 mm - 6-leveler (6-hi) leveler x 2units types -- Tension: 45 to 50 kg/mm2 -- Yield point: 28 kg/mm2 - Cutting method: Cut while running (flying), numerically controlled rocking type - flying shears -- (Cutting speed) 20–40/80 m/min -- Speed 2-speed change type --- 0.3 to 1.2 mm: 20 to 80 m/min --- 0.21–3 mm: 20–40 m/min -- Slow operation: 0.8 m/min -- Conveyor speed: 20~120m/min -- Cut count: up to 150 cuts/min -- (Product piling) --- Plate width: 500–1350 mm --- No1 piler: 400 to 3100 mm (also used as a reject filer) --- No2 piler: 400–6100 mm --- Load height: up to 600mm --- Load weight: up to 4 tons Line direction: From right to left on control panel Line: Approximately 13 m x 49.050 m (Major facilities) - Coil skid - Coil car - Pay off reel and a paper winder - Coil opener - Rough Leveler - Shear - No. 1 Looper Guide - Side guide and pinch roller - Side trimmer - Scrap winder x2 - No.1 Finisher Leveler (6-hi) - No2 Finisher Leveler (6-hi) - No 2 Looper Guide - Measuring roller, feed roller and paper-off reel - Shear - Conveyor - Cart - No1/No2 piler type - Hydraulic unit: Type - Valve stand type - (Coil skid) -- V-type fixed skid -- Coil maintenance: 1 coil -- Coil weight: up to 15 tonnes -- Coil diameter: 600 to 1800 mm -urethane rubber (Coil Car) Cradle roller type Hydraulic boost Electricity transfer driving type Two guide lots hydraulic cylinder elevating type (payoff reel and paper winder) Overhang, single-mant 4-segment type Paper reel motor: DC 5.5KW 400/1600 RPM, attached to brake Paper winder: cone type, (motor DC 1.5KW, 1750 RPM) (Coil Opener) Knife edge method (Rough Leveler) 2-stage (2hi) 5-body roller leveler Pinch rollers: 160 mm × 1450 mm 2 pieces, The upper part of the pinch roller is hydraulic cylinder press-down, and the lower roller is fixed 5 workload rollers 130mm x 1450mm The upper roller of the workload roller is electrically pressed, and the lower roller is fixed 0–40/80 m/min Two-stage change 0.3 to 1.6 mmt: 80 m/min 1.7 to 1.6 mmt: 40 m/min Motor: DC 18.5 KW, 1750 RPM, Brake Attachment Pressing motor: 2 1.5KW 100RPMs with brakes (Shear) Hydraulic up cut shear Knife size: 25 mm thickness × 150 mm width × 1450 mm length (No. 1 Looper Guide) Table lift Hydraulic cylinder operation method Loop: Light Volume Control Method Roller: 70 mm diameter × 1450 mm × 6 bonds, rubber lining roller (Side guide and pinch roller) Vertical Free Roller Electrically switched type Side guide roller: 90 mm diameter × 150 mm length × 6 bones Pinch Roller: 2nd Stage (2hi) Roller: 160 mm diameter × 1450 mm length × 2 bones Upper roller: pneumatic cylinder pressure free roller Lower Roller: Fixed Drive Roller (Side trimmer) Overhang Drive Cut 0–40/80 m/min 2-stage change type 0.3 to 1.6 mmt: 80 m/min 1.7 to 1.6 mmt: 40 m/min Cutter diameter: 320 mm / 190 mm internal diameter × 20 mm thickness Roller: 320 mm external diameter × 19 mm internal diameter × 20 mm thickness Motor: DC 5.5KW 1750RPM (Scrap winder) Two machines Link Pin Gauge Type (Hydraulic Cylinder Opening and Closing Type) Motor: 2 DC 2.2KW 1450 RPM (No1 Finisher Leveler) 6-level (6-hi) 17 leveler Thickness: 1.21–3.0 mm Speed: 6 to 40/80 m/min Thickness 0.3–1.2 mm 6–80 m/min Thickness 1.21–3 mm 6–40 m/min Pinch roller: 180 mm × 1750 mm × 2 bones The upper roll is a pneumatic cylinder. The lower roll is fixed Rubber lining drive roller Work roll: 60mm x 1750mm x 17e 8 for the upper roll, 9 for the lower roll Plated abrasive roller Medium roller: 50 mm × 1750 mm × 19 pieces 9 for the upper roll, 10 for the bottom roll Backup Roller: 88 mm Diameter x 50 mm Length x 7 rows Pressing Method: Lower Roller Parallel Pressing Pressing speed: 0.25 mm/sec Pressurization: plus or minus 5 mm Motor: DC 55KW 1750 RPM Brake Attachment (No2 Finisher Leveler) 6-level (6-hi) 17 leveler Plate thickness: 0.3–1.2 mm Speed: 5 to 80 m/min Pinch roller: 180 mm × 1750 mm × 2 bones The upper roll is a pneumatic cylinder. The lower roll is fixed Rubber lining drive roller Work roll: 35mm x 1750mm x 17bon 8 for the upper roll, 9 for the lower roll Plated abrasive roller Medium Roller: 32 mm × 1750 mm × 19 pieces 9 for the upper roll, 10 for the bottom roll Backup Roller: 99 mm Diameter x 50 mm Length x 7 rows Roller bearing type Pressing Method: Lower Roller Parallel Pressing Pressing speed: 0.25 mm/sec Pressurization: plus or minus 5 mm Motor: DC 35KW 1750RPM Brake Attachment (No. 2 Looper Guide) Table lift Hydraulic cylinder operation method Loop: How to control the amount of light (amount of light) Roller: 70 mm diameter × 1450 mm × 6 bonds, rubber lining roller (Measuring roll/feed roller/paper vinyl payoff reel) Measuring roller: The upper roll is pneumatic pressing, the lower roll is fixed, the pressing amount is 30 mm Feed roller: Upper roll is pneumatic cylinder press, lower roll is fixed, press load is 40 mm Motor: DC 2.2KW 1750RPM (Shear) Fluctuating Flying shear 0.3~3mm Speed: 2 groups of 20–40/80 m/min Thickness 0.3–1.6 mm 80 m/min Tlate thickness 1.6–3 mm 40 m/min Cut count: up to 150 cuts/min Cutting length: 400–6000 mm Electric up CUT shear Cut up and down knife die via motor, reducer, pinion stand crankshaft Knife: 20 mmt × 80 mm × 1400 mm × 1 set The top knife is a straight knife, and the bottom is a V-lock knife Adjustment: Wedge Motor: DC 75KW 550RPM (Conveyor) Belt conveyor type Belt width: 1200 mm Conveyor length: 3800 mm Motor DC 5.5KW 1450RPM Brake Attachment (No. 1 No. 2 piler) No1 piler: Combined use of reject truck, air blower Combined use of side conveyor No2 piler: Combined suction conveyor and air blower Loading height: 600 mm Lift: Hydraulic lift volume 650 mm Motor: 4 1.5KW 150RPM units for side guide end stoppers 2.2 KW 1500RPM for lifters 1.5KW for cart 7.5KW for blower (Hydraulic device) 70 kg/cm2 × 100 L/min Pen pump Motor: DC 18.5 KW 1000 RPM (Supply power) AC400 V,50 Hertz 3 Phase / AC200 V,50 Hertz 3 Phase (Control power) AC 200V, 50 Hz Single Phase (Compressed air) Compressed air required: 5 kg/cm2

Datasheet

Request / Contact

- SCHMITT REINHOLD GMBH

- Obernahmerstr. 74

- 58119 Hagen-Hohenlimburg

- Deutschland

-

+49 (0)2334 4847

+49 (0)2334 4840 -

info@reinhold-schmitt.de

www.reinhold-schmitt.de

#2008-056410 · Cut-to-length-lines

WILHELMSBURGER - - - 1975 -

Technical details

length tolerance ± 0,5 mm width tolerance ± 0,5 mm diagonal tolerance ± 1,0 mm line consisting of: double side decoiler leveler no. of leveling rolls 21 leveling roll diameter 35 mm flying shear magnetic conveyor table - length 10 m 2 output tables electric pneumatic hydraulic

Datasheet

Request / Contact

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-M825 · Cut-to-length-lines

Hydro Meca - 90L4C108H - - -

Technical details

Pipe cutting machine

Laser Cutting Machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2500026 · Laser Cutting Machine

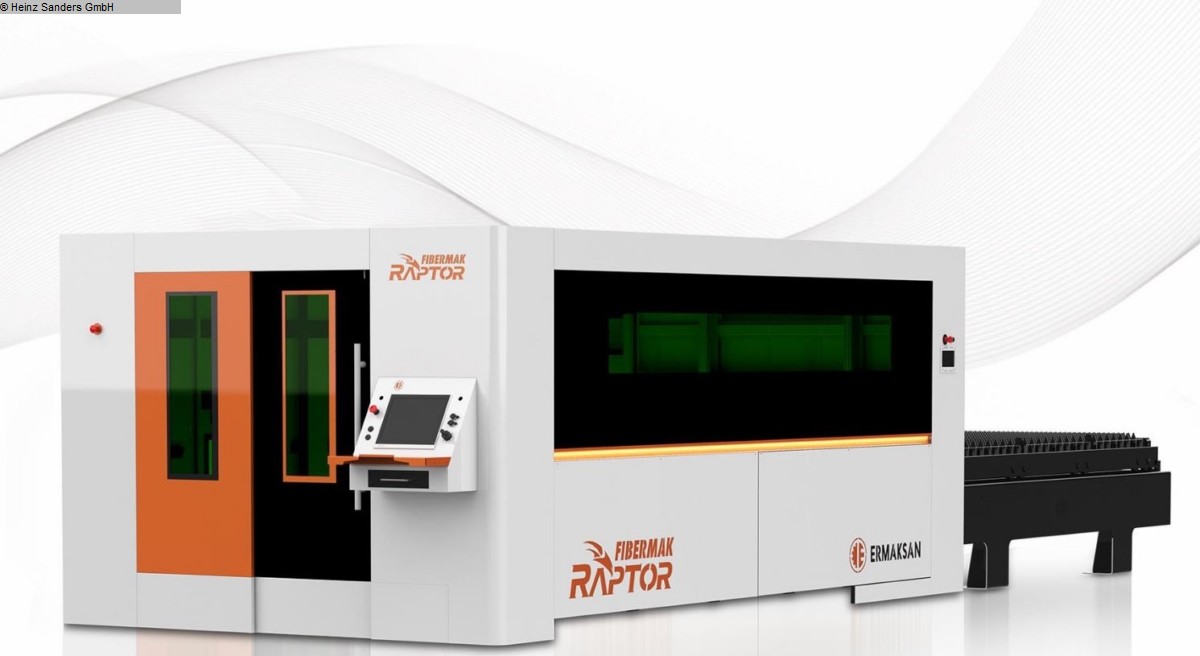

ERMAK - FIBERMAK RAPTOR 6KW - - NEU - CNC

Technical details

CUTTING CAPACITY: STRUCTURAL STEEL 25 mm STAINLESS STEEL 15 mm ALUMINUM 12mm BRASS 8mm COPPER 8mm MACHINE AXES: 4 axes [X, Y, Z, U ] CUTTING HEAD: Precitec ProCutter CAD/CAM SOFTWARE: LANTEK EXPERT CUT *4 servo motors for all axial movements *CNC CONTROL PANEL 15 5” touch screen *IPG laser sources and coolers integrated *Precitec Procutter cutting head system *AIR FILTER (compressed air filter) *CONVEYOR BELT under cutting area *Closed housing and specially coated filter protection windows *LOADING / DISCHARGING SYSTEM *PROPORTIONAL GAS AND PIPE SYSTEM

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7286 · Laser Cutting Machine

ERMAK - FIBERMAK SM 6000.3 x 1,5 - - NEU -

Technical details

Furnishing: - Resonator Ytterbium YLS 4000 compact - Beckhoff controller - Precitec ProCutter Automatic cutting head - autom. Lubrication system - CAD / CAM software LANTEK EXPERT CUT - 17 "touchscreen, keyboard, control panel - Collective conveyor under the cutting table - additional loading unit Cutting capacities: - normal steel 25 mm - stainless steel 15 mm - aluminum 12 mm - brass 8 mm - copper 8 mm Axes: - Machine axes: 4 axes (X, Y, Z, U) - max.axis speed: 100 m / min (simulated) - Axis speed X / Y: 100 m / min (single) - Positioning accuracy: + - 0.03 mm / min - Burning height: 125 - 200 mm Loading table: - Number of pieces 2 (35 seconds for changing) - automatic change of tables - max.load 2,500 kg. assisting gases: - mild steel - oxygen (0.5 - 25 bar) - stainless steel - nitrogen (0.5 - 25 bar) - Aluminum - compressed air or nitrogen (0.5 - 25 bar) including: - Compatible suction system - Sick light barrier safety device - Spare part basic supply package Why Fibermak? - Up to 3 times faster cutting compared to other laser technologies - Machines for cutting thin sheets - axes equipped with linear motors / Servo motors reach up to 141 m / min. - Accelerations up to 2G - Fiber laser is the green laser technology (Saving of at least 50% energy costs) - There is no need for laser gas mixing - There is no need for optical Components / therefore very low-maintenance - Save up to 50% per part through more efficient production - Extended options: cutting from reflective materials like aluminum, copper, brass etc., - In addition, precise cuts and smooth surface quality - Heavy-duty constructed frame, equipped with world-famous, durable, high-quality components - ERMAK passes the price advantage on to its customers thanks to its fast and high quality production - Creative design, constant, highest technology and quality - High reliability - High efficiency - High quality - CE declaration

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7255 · Laser Cutting Machine

ERMAK - FIBERMAK SM 4000.3 x 1,5 - - NEU -

Technical details

Furnishing: - MOMENTUM GEN - 2 fiber laser cutting machines 3,000 x 1,500 mm - Ytterbium YLS 4000 compact resonator (4 kW) - PRECITEC PROCUTTER laser cutting head - CAD / CAM software BECKHOFF - Controller CP 6242 - 17 "touchscreen, keyboard, control panel, alphanumeric keyboard - Collective conveyor under the cutting table - additional loading unit Cutting capacities: - normal steel ... 20 mm - stainless steel ... 12 mm - aluminum ... 10 mm - brass ... 6.0 mm - Copper ... 5.0 mm Workspace: - max .: 3,000 x 1,500 mm Axes: - Machine axes: 4 axes (X, Y, Z, U) - max.axis speed: 100 m / min (simulated) - Axis speed X / Y: 100 m / min (single) - Positioning accuracy: + - 0.03 mm / min - Burning height: 125 - 200 mm Loading table: - Number of pieces 2 (35 seconds for changing) - automatic change of tables assisting gases: - mild steel - oxygen (0.5 - 25 bar) - stainless steel - nitrogen (0.5 - 25 bar) - Aluminum - compressed air or nitrogen (0.5 - 25 bar) included : - Compatible suction system - Light barrier safety device - Spare part basic supply package Why Fibermak / Fiberlaser? - Up to 3 times faster cutting compared to other laser technologies - Machines for cutting thin sheets - Axis speed: reach up to 141 m / min. - Accelerations up to 2G - Fiber laser is the green laser technology - Saving of at least 50% energy costs) - There is no need for laser gas mixing - There is no need for optical components - therefore, among other things, very low-maintenance - Save up to 50% per part through more efficient production - Extended options: cutting reflective materials * like aluminum, copper, brass etc., - In addition, precise cuts and smooth surface quality - Heavy-duty constructed frame - equipped with world-famous, durable, high-quality components - Creative design, constant, highest technology and quality - High reliability - High efficiency - High quality - CE declaration

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-92160 · Laser Cutting Machine

DURMA - FL-3015-L-6kW - - 2019 -

Technical details

demonstration machine FANUC 6000 W fiber laser source, automat. beam centering, DENER Smart Nest, Air Dryer, DENER Filter, Camera & Surveillance, air-conditioned control cabinet, Precitec Procutter cutting head, shuttle table, automatic nozzle cleaning, central lubrication, scrap pan for small parts etc. dirt, METALIX Pronest automatic nesting, multi-chamber suction system, warning lamp

Datasheet

Request / Contact

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3211 · Laser Cutting Machine

Amada - Ensis AJ 6kW - - 2019 -

Technical details

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100512 · Laser Cutting Machine

TRUMPF - TruLaser 5030 Fiber (L68) - - 2018 -

Technical details

The machine is in good condition. 1. Option: Machine installation, operator training at buyers location and partially refurbishing including function guaranty: Surcharge 14.800 € plus Transport and traveling costs 2. Option: Workshop refurbished machine including technical approval by manufacturers’ directive at our workshop. Machine installation, operator training and free delivery of spare parts for 6 months after installation. Surcharge: 38.300 € plus Transport and traveling costs. Delivery time +6 weeks. Standardequipment machine: - closed machine frame with integrated laser unit, - movement unit for highly accurate processing, - Toryue-drive in combination with linear direct drive, - closed beam line, - a cutting head strategy, - cooling unit, - automatic pallet-changer in the longitudinal direction, - Conveyor, - 17" touch colour screen, - Work space lighting, - position laser diode, - spray device, - PierceLine, - NitroLine, - PlasmaLine Cutting head - LensLine, - Lens cutting head with 250mm focal length, - ControlLine Control - workshop programming, - simple workshop programming dir. Of DXF, - integrated technology files, - shutdown, - production plan, - programmable cutting gas pressure selection, - SprintLine, - ContourLine, - Microweld, - FastLine, - AdjustLine, - Teleservice, - diagnostic functions, - online-help, - FlyLine Date transmission - USB-interface, - RJ-45 network, Safety - CE-identification, - light barriers, - laser monitoring system, - more chambers extraction plant, - compact dust, - machine-cladding with Makrolon panels

- René Reiser Grafische Maschinen

- Höhenstrasse 5+7

- 75242 Neuhausen

- Deutschland

-

+49 (0) 7234-95310

+49 (0) 7234-953131 -

info@reiser-gm.de

www.reiser-gm.de

#2074-403 · Laser Cutting Machine

SEI Laser - GIOTTO CO2 3ax Compact 300 - - 2017 -

Technical details

Datasheet

Request / Contact

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3188 · Laser Cutting Machine

Trumpf - TruLaser 3030 - 3kW Fiber - - 2017 -

Technical details

TOP Manufacturer:

DREHER - 1SCHLEICHER/GSW - HENSEL - TEAP - KOHLER / WEINGARTEN - NORMATIC - SCHARF WESTFALIA - SCHLEICHER - GSW - DIMECO -