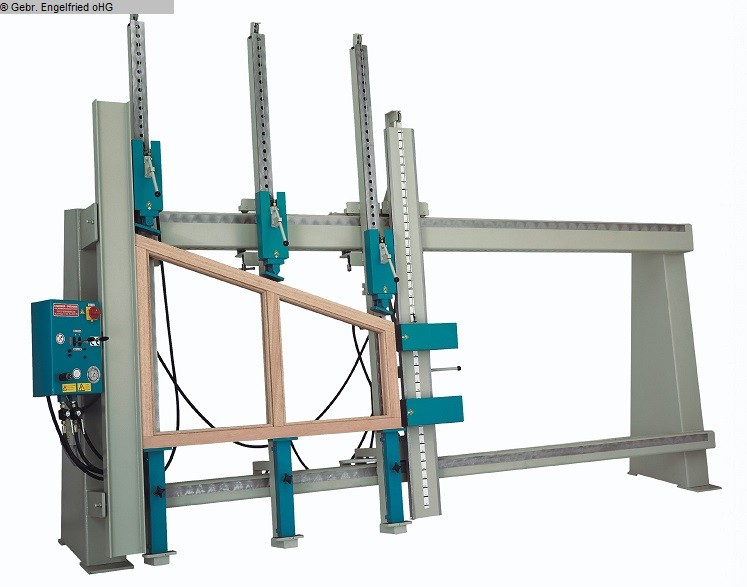

Frame press

Machinelist: Frame press

Boring machine for fittings

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6265 · Boring machine for fittings

GÖTZINGER - OBM Plus - - neu -

Technical details

Olive drilling machine type OBM-PLUS (corner and shear bearing + handle olive drilling) Drilling unit vertical with drill head quick-change device Pneumatic feed via foot valve 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/400V, 50Hz, 1.1KW Machine without drilling head, without drilling tool ----------------------------------------------------- Basic price in the above version on request! Options with additional prices: -Drilling head BKF 3, 21.5 mm pitch, quickly changeable -1 set of drill bits for handles 2 dowel drills d=10 left 1 artificial drill d=25 -Drill head BKF 2/3 quick-change drill 2/3 spindles for corner bearings on the loose frame part (Sigenia, Maco, Roto, Winkhaus, GU) complete with stop system with 2 folding stops -Drill 2 cylinder head drill bits for corner bearing Special accessories: -folding stops -Stop system for central drilling -Landing gear We would be happy to send you the price list with all options on request. (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6264 · Boring machine for fittings

GÖTZINGER - OBM 1 - - neu -

Technical details

Olive drilling machine type OBM 1 Standard version (only handle olive drilling) Drilling unit vertical complete with drill head BKF 3, 21.5 mm pitch Drill mount M 10, cyl. right/left Pneumatic feed via foot valve Spring-loaded hold-down devices Stop system 2200 mm Total length with 10 folding stops adjusted to fitting 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/380V, 50Hz, 1.1KW Machine complete, but without drilling tool ----------------------------------- Price in the above version on request! Options with extra charge: -1 set of drills consisting of: 2 dowel drills d = 10 left 1 artificial drill d = 25 (or according to choice or manufacturer's fitting) -folding stops -Stop system for central drilling -Landing gear -Roller conveyor right/left 1.5 m, 200 mm wide complete with 4 rolls each - Packing 1 box Packaging 1 pallet with foil We will be happy to send you the complete price sheet on request! (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2714 · Boring machine for fittings

HESS - Bohrstation Ecklager+ Olive - - gebraucht -

Technical details

Hess corner bearing and olive drilling machine ---------------------------------- - Stable base frame as a support wall - precise support made of abrasion-resistant and dimensionally stable plastic for frames and sashes up to 100 mm thick - Corner bearing and olive drilling in one machine and in one Drilling unit - easy and comfortable vertical work - easy handling - no templates, minimal Time required for safe workpiece positioning, Guarantee for exact and precise holes - 2 clamping cylinders for immovable fixation of sashes or frame adjustable to different wood thicknesses - Lateral stop in the rebate for the corner bearings - Ergonomically arranged stop system for olive drilling with 14 hinged stops and additional color markings - fixed stop system for borehole - height determination when changing Corner camp to Olive - automatic drilling depth sensing for corner bearing and olive - Drilling unit with quick-change chuck for the various tools for corner bearing and olive - Tool change “in the blink of an eye” - automatic program flow - clean work thanks to effective suction - Small space requirement and mobile thanks to swivel/brake casters Electrical equipment according to VDE Electrical connection: 0.55 kW, 400 volts, 3/N, PE, 50 Hz Pneumatic connection: R 1/4", min. 4 bar, max. 8 bar Air consumption: 7 NL / cycle Suction connection piece: 1 x 80mm diameter Suction speed: 25 m/sec. External dimensions/floor dimensions/space requirements: Width: 2600mm Height: 1250mm Depth: 800mm Support height: 300 mm Weight: 310kg Paint finish: RAL 7030 stone gray with 1018 zinc yellow ---------------------------------- (Technical description according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2698 · Boring machine for fittings

GÖTZINGER - OBM-Plus - - gebraucht -

Technical details

Corner bearing and olive drilling machine Götzinger OBM-PLUS Vertical drilling unit with quick-change device Pneumatic feed via foot valve 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf Left and right roller conveyor each 1.5 m, 200 mm wide, 4 rollers each 220/380V, 50Hz, 1.1KW 1 drill head BKF 3, 21.5 mm pitch, quick-changeable Drill mount M 10, cyl. right/left complete with stop system 2200 mm long Total length with 12 folding stops adjusted to a constant grip dimension (olive drilling) Consisting of: 2 dowel drills d=10 mm 1 artificial drill d=25 mm 1 drill head BKF 2/3 quick-change drill 2/3 spindles for corner bearing on the loose frame part. Hardware Roto- alternative on request Complete with stop system with 2 folding stops Drill mount: M 10 right/left 2x7 mm and 34 mm (Technical description according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6841 · Boring machine for fittings

GÖTZINGER - OBM Plus - - gebraucht -

Technical details

Olive drilling machine type: OBM-Plus Special version (corner and scissor bearing + handle olive drilling) --------------------------------- Vertical drilling unit with quick-change device Pneumatic feed via foot valve 1 adjustable back stop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/380V, 50Hz, 1.1KW Machine complete, but without drilling tools Drill head BKF 3, 21.5mm pitch, quick-changeable Drill holder M 10, cyl. right/left complete with stop system 2200 mm long Total length with 10 folding stops set to a constant grip size (for handle olives) Drill head BKF 2 can be changed quickly 2 spindles for corner bearings drill on the loose frame part complete with stop system with 2 folding stops Drill consisting of 2 pieces of dowel drills d = 12 mm left 1 piece of artificial drill d = 25 mm right Drill 2 cylinder head drills for corner bearings Stop system for center drilling landing gear Roller conveyor right/left 1.5 m, 200 mm wide complete with 4 rolls each 2 additional stops for picking the fighter groove Fitting: Siegenia Titan AF latest version with 30mm double pot Installation dimensions: 3600 x 800 x 1900 mm -------------------------------- Price of the above machine on request! -------------------------------- Option: Prices for other drilling heads (other hardware) on request (Technical information according to the manufacturer - no guarantee!

Datasheet

Request / Contact

Frame press

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6794 · Frame press

S&S - Bavaria 2000 L - Video - - Vorführpresse -

Technical details

S&S frame press Bavaria 2000 L --------------------------------- With automatic pressing cycle + manual control for corner connections tenon + slots and dowel connection / mortised tenon, can be changed using a selector switch on the control cabinet. With basic equipment for the optional use of counter profiles if the sash is on loose part to be folded over. CE version Basic machine in the strongest welded frame, with thick-walled special hollow profiles. Guideways of the pressure bars for the press corners in a low-abrasion finish. Fast, smooth, manual width adjustment by ball-bearing carriage, fixation in 50 mm Hole grid, optional motorized width adjustment with with hydraulic clamping (surcharge). Height adjustment and pressing by long-stroke cylinder in one work cycle. Right-hand press corners with integrated horizontal cylinders, therefore none vertical positioning of the horizontal printing cylinders necessary, avoiding cylinder collisions. Abutments below in several positions on each most favorable insertion height adjustable. 3 KW compact hydraulic system with integrated Control block, variable pressure control from 20 - 120 bar, manometer Control via push button with separate control circuits for the vertical and horizontal press cylinders on a freely movable control panel. 2 vertical press cylinders, double-acting, stroke on Adjusted working height, piston diameter 60 mm Pressure force per cylinder max. 2100 kg 2 horizontal press cylinders, double-acting, 80 mm stroke, piston diameter 40 mm Pressure force per cylinder max. 1250 kg Abutment and pressure plate depth 100 mm Control cabinet on the machine base on the left, 400 volts, 50 Hz Machine with ready-to-connect plug 16 A Paint finish: RAL 7035 light gray with RAL 7016 anthracite grey Working size: length x height = 4,500 mm x 2,750 mm A notice: actual working size: 4,500 x 3,000 mm (length x height= Space required: 5,600 mm x 1,350 mm x 3,550 mm (length x width x height) Item 0000127 ------------------------ Press height modification 2750/3000 mm a The machine is supplied with a 3,000 mm high pressure bar The cylinder attachment and the positions of the lower press corners however, correspond to the version with a press height of 2,750 mm. By installing 3 pieces of 300 mm long piston rod extensions the max. pressing height can be increased to 3,000 mm. Using the tools provided, it is possible to convert the Machine possible within approx. 10 minutes. Insertion heights: - lower insertion height for sashes with width <550 mm; approx. 1280 mm - Insertion height upper edge of upper horizontal frame wood up to pressing height 2,750mm; approx. 1,620 mm - Insertion height upper edge of upper horizontal frame wood pressing height >2,750mm; approx. 1,920 mm (piston rod extension installed) Scope of delivery: 1 piece support plate 3 piston rod extensions 300 mm 1 open-end wrench size 30 1 ratchet with socket wrench size. 24 1 piece holder for piston rod extensions and tool Hints: - The height is corrected for machines with a positioning function by parameter switching. Operation of the machine with the built-in piston rod extensions is replaced by another wallpaper displayed. - Total height of the machine approx. 3,400 mm Item 00001147 ------------------------ 1 medium pressure bar complete with pressure cylinder, Pressure hose and shut-off valve up to 3,000 mm high Item 00000471 ------------------------ Individual pressure control for medium pressure bar, Pressure control range up to max. 100 bar (For pressing crossbar windows) Item 00000112 ----------------------- infinitely height-adjustable transverse pressure device, complete with pressure cylinder and abutment, Throttle and shut-off valve Item 00000481 ------------------------ Individual pressure control for transverse pressure device Pressure control range up to max. 100 bar (For pressing crossbar windows) Item 000000391 --------------------------------------- Shut-off valve on the 3rd vertical cylinder Item 00000391 ----------------------- Shut-off valve on the upper horizontal cylinder Item 00001005 ------------------------ 3 x inclined window controls for vertical cylinders Item 00000302 ----------------------- 3x pendulum pressure plates attachable for pressing up to 60 degrees Item 00000631 ----------------------- double pendulum pressure plate for pointed windows (triangle) Item 00000113 ----------------------- 2 x extension for pendulum pressure plate for pointed windows (triangle) Item 00000057 ----------------------- Intermediate allowance for small dimension pressing for bridging the 1st pressure bar, including shut-off valve on the 1st vertical cylinder Item 00000100 ----------------------- Motorized width adjustment with digital display Item 00001001 ----------------------- Machine equipped for pressing of "tenons + slots" and additional pressing cycle for pressing "dowel connection" or "Plugtec", changeable via selector switch on the control cabinet Item 00001003 ----------------------- Basic equipment for counter profiles Item 00000632 ----------------------- Electronic pressure preselection device For 4 different, permanently programmed pressure levels (can be changed at any time), and an additional freely selectable one Pressure level directly on the control panel Item 00001002 ----------------------- 6x printing unit support and printing plate depth 120 mm Item 00099000 ----------------------- all pressure plates and abutments covered with plastic --------------------------------- Total price in the above version: on request! Options with additional prices: ----------------------- Item 00001004 ----------------------- Counter profiles, price per piece: 260.00 euros Further options such as other working dimensions on request! (Technical information according to the manufacturer - without guarantee! Illustrations may be dated Deviate from the original, prices net, plus VAT (domestic))

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6792 · Frame press

S&S - RP 2000 - - Vorführmaschine -

Technical details

S&S frame press type RP 2000, ----------------------------- C E - version Stable frame welded construction made of thick-walled special hollow profiles, Sliding carriage and pressure bar with 50 mm hole pattern. Continuous abutment on the left for width compression, lower abutment in two levels. Vertical press cylinder on special pressure bar with one-hand quick adjustment with weight compensation in the 50 mm hole pattern, height-adjustable, long Sliding carriages ensure the permanent absorption of high pressing forces. Fast, smooth width adjustment with ball-bearing carriage Central locking, fixation in 50 mm hole pattern. Upper horizontal press cylinder infinitely adjustable in height and with Equipped with counterbalance. Lower horizontal press cylinder with center holes for the two Abutment levels, with weight compensation. Abutment and pressure plate depth 100 mm Printing plate and support width 130 mm Machine electro-hydraulically controlled, with 2 vertical pressure cylinders d = 50 mm, stroke 120 mm double-acting, with counterweight and One-hand quick adjustment, 2 pieces Horizontal pressure cylinders d = 40 mm, stroke 120 mm double-acting, with weight balancing; 2 manual control valves, Pressure gauge, 1 pressure control valve from 20 to 125 bar corresponds to 400 to 2400 kg pressure vertical, with 3 kW three-phase motor for 400 volts, 50 Hz operating voltage. Complete with electrical connection. Paint finish: RAL 7035 light gray with RAL 7016 anthracite grey Working size: 4000mm x 2600mm (length x height) Required space: 5300 x 1250 x 3330 mm (L x W x H) Machine including the following options: -------------------------------------- Article 00000374 1.00 pc Medium pressure bar with pressure cylinder double-acting, weight compensation, pressure hose and shut-off valve up to 2600 mm high Article 00000047 1.00 pc Individual pressure control for medium pressure bar, Pressure control range up to max. 100 bar (for pressing crossbar windows) Article 00000038 1.00 pc Cross printing device complete with pressure cylinder double-acting, weight compensation, pressure hose and shut-off valve There is no weight compensation on the lower horizontal cylinder Article 00000048 1.00 pc Individual pressure control for transverse pressure device, Pressure control range up to max. 100 bar (for pressing crossbar windows) Article 00000039 1.00 pc Shut-off valve on the 3rd vertical cylinder Article 00000039 1.00 pc Shut-off valve on the upper horizontal cylinder Article 00000050 1.00 pc Width allowance for compression of small frames to bridge the 1st pressure beam, including shut-off valve on the 1st vertical cylinder Article 00003117 1.00 pc Basic equipment for counter profiles The space required in height increases by 100 mm Item 00099000 All pressure plates and abutments covered with plastic Article 00000049 1.00 pc Triangle studio window pressing device consisting of: locking device of Vertical pressure bar and 3 attachable, side-guided pendulum pressure plates Article 00000063 1.00 pc double pendulum pressure plate for pointed windows (triangle) -------------------------------------- Total price in the above version ex works: On request! -------------------------------------- Options: Article 00000042 1.00 pc Machine that can be dismantled i.e. H. Pressure bar on pallet -------------------------------------- Further options such as other working dimensions on request! (Technical information according to the manufacturer - without guarantee! Illustrations may be dated Deviate from the original, prices net, plus VAT (domestic))

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5956 · Frame press

S&S - Multipress Lochplattenpresse - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5845 · Frame press

S&S - RP 2000 - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6030 · Frame press

S&S - T 35 - - neu -

Technical details

Stable frame welded construction of thick-walled Special hollow profiles , sliding table and pressure beam with 50 mm hole pattern . On the left side continuous abutment for grouting the wide , lower abutment in 2 levels. Vertical pressing cylinder on specialty bar with one- quick adjustment with weight compensation in the 50 mm hole pattern adjustable in height. Long sliding table ensure the continuous recording of high jacking forces . Fast, smooth width adjustment with ball bearing Carriage with central fixation in 50 mm hole pattern. Upper horizontal press cylinder infinitely adjustable in height and equipped with counterbalance . Lower horizontal pressing cylinders with bore for two abutments levels without weight compensation . Abutment and pressure plate depth 100 mm Machine controlled electro -hydraulic with 2 pieces vertical pressure cylinders d = 60 mm, stroke 120 mm, single-acting, with counterbalance and One-hand height adjustment, 2 piece horizontal pressure cylinders d = 40 mm stroke, 120 mm single-acting ( 1 x with weight compensation ), 2 hand control valves , Pressure gauge, pressure regulator valve 1 of 20 to 150 bar corresponds to 550 4200 kg compression force vertically. With 3 kW three-phase motor for 400 volts , 50 Hz Operating voltage. Complete with electrical connection . Painting RAL 7035 anthracite gray with light gray RAL 7016 . (technical details according to manufacturer - without guarantee ! ) The detailed technical description can be found in the attached pdf file

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6121 · Frame press

S&S - Super-Video - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6496 · Frame press

S&S - Bavaria 2000 L -Video - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6852 · Frame press

HESS - Hydro Spezial - - gebraucht -

Technical details

500 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6803 · Frame press

SCHAFBERGER + SPROEDHUBER - RP 1200 - - gebraucht -

Technical details

S+S hydraulic frame press RP 1200 ------------------------------------- Working width 3,550 mm Working height 2,250 mm ------------------------------------- with medium pressure beam ------------------------------------- still in use ------------------------------------- Technical information according to the manufacturer - without guarantee!)

2.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2719 · Frame press

HESS - Speedy Video - - gebraucht -

Technical details

Hess Speedy frame press -------------------------------------- Press will be checekd Insertion dimension / pressing length max. 3,550 mm Insertion dimension / pressing height max. 2,250 mm Sliding carriage for width adjustment locking in 50 mm Double hole grid system Electric height adjustment of the long-stroke cylinders (hydraulic) Insertion height of the abutment plates can be preselected in 4 positions 3 vertical printing cylinders stroke 1000 mm Pressure force per cylinder 2000 kN / 20000 N 2 horizontal printing cylinders stroke 80 mm Pressure force per cylinder 1250 kN / 12500 N Printing plate depth 100 mm width 140 mm Grid for cylinder fixation/rear bearing 50 mm Medium pressure beam with shut-off valve Final pressure switch-off and pressure control Control and pressing process in touch button operation Adjustable pressing pressure min. 25 – max. 160 bar Electrical connection 2.2 kW / 400V Control for studio window gluing 2 pendulum pressure plates 45 degrees Machine dimensions W=4500 mm, D=900 mm, H=2600 mm Weight approx. 1800 kg Photo and video not original, shows press of same type. (technical data according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2701 · Frame press

HESS - Quickstep_Video - - gebraucht - Siemens S7-1200

Technical details

#2701 Hess Quickstep frame press -------------------------------------- Technical data summary (please inquire about any additional accessories included) -------------------------------------- Generally -------------------------------------- Working width: 3500 mm Working height: 2250 mm Total power requirement: 3 kW Installation dimensions: 4500x980x2610 mm Loading dimensions: 4500 x 980 x 2610 mm Machine weight, approx.: 2000 kg Characteristics: -------------------------------------- > hydraulic: yes > Number of vertical press cylinders: 3 > Number of horizontal press cylinders: 2 > Vertical adjustment type: electric (long-stroke cylinder) > Horizontal adjustment type: electrical > 1 medium pressure bar > Printing plate depth 100mm width 140mm > 3 pcs. pendulum pressure plates > 1 piece small parts allowance Other features -------------------------------------- Opto-electronics, i.e. fully automatic measurement and setting, horizontal Siemens S7-1200 control (technical information according to the manufacturer - no guarantee!) Pictures and video show the original press stock number 2701.

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2730 · Frame press

HESS - Speedy, 2 Mitteldruckbalken - - gebraucht -

Technical details

Hess Speedy frame press with 2 medium pressure beams! -------------------------------------- Insertion dimension / pressing length max. 3,050 mm Insertion dimension / pressing height max. 2,050 mm Sliding carriage for width adjustment locking in 50 mm Double hole grid system Electric height adjustment of the long-stroke cylinders (hydraulic) Insertion height of the abutment plates can be preselected in 4 positions 4 vertical printing cylinders stroke 1000 mm Pressure force per cylinder 2000 kN / 20000 N 2 horizontal printing cylinders stroke 80 mm Pressure force per cylinder 1250 kN / 12500 N Grid for cylinder fixation/rear bearing 50 mm Medium pressure beam with shut-off valve Final pressure switch-off and pressure control Control and pressing process in touch button operation Adjustable pressing pressure min. 25 – max. 160 bar Electrical connection 3.0 kW / 400V Machine dimensions W=3970 mm, D=950 mm, H=2400 mm Weight approx. 1680 kg Machine is currently being checked - picture not original, shows same model. Video shows press from our archive (technical data according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6821 · Frame press

CASOLIN - Euro - - 2010 -

Technical details

Casolin Euro ------------------------- HYDRAULIC FRAME PRESS FOR WINDOWS AND DOORS CASOLIN MOD. "EURO" Frame press in an extremely stable steel construction. The machine also allows the pressing of already milled wing and frame parts. Working dimensions: 6000mm x 3000mm Installation dimensions: Total length: approx. 7,175 mm Installation height approx.: 3,790 mm + 340 mm (cylinders look when pressed maximum pressing height above) = 4,130 mm Loading dimensions: Length: approx. 7,175 mm Height: approx. 3,790 mm Weight: approx. 3,700 kg (technical data according to the manufacturer - no guarantee!)

20.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6822 · Frame press

MAWEG - Euronova Qickomat - - 1996 -

Technical details

Maweg Euronova Quickomat frame press ---------------------------- with automatic measurement adjustment. Cylinder max. opened (maximum working dimensions) W 3,648mm x H 2,485mm Total length: 4,720mm + 400mm control unit Total height: 3,550 mm (technical information according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

TOP Manufacturer:

S&S - HESS - MAWEG - SCHAFBERGER + SPROEDHUBER - CASOLIN -