Knops Werkzeugmaschinen GmbH & Co. KG - Stockist for used machines

Machinelist:

Machining Center - Horizontal

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E05884 · Machining Center - Horizontal

MCM - ACTION 2600 FFS - - 2008 - Fanuc 16 MB

Technical details

The system requires a space of approx. 42 x 18 m It is designed for "fully automatic operation" in 3 shifts. Components with tolerances of <0.01 mm were produced on the system. Equipment: CNC control Fanuc 16 MB 20-pos pallet changer Pallet size 1250 x 1000 mm Interference circle diameter up to 2700 mm Vertical tool magazine with 599 places HSK-A100 from 3 modules on 4 levels Rotary table (B-axis) with 3,600,000 angular positions Table load 4000 kg Spindle speeds 8,000 rpm. Motor power 26/37 kW Torque 605/707 Nm Chip disposal through two jet pipes in the existing central Chip disposal system Connection to an in-house central coolant system. IKZ spindle with supply of coolant through the center of the tool Cooling unit for working spindle use Electrical control cabinet with air conditioning Protective cover for the work area Protective fence cladding, sheet metal below and safety glass above, for the entire working area of ??the machine. Buffer shelf with 5 tool spaces for quick tool provision Tool cone cleaning High pressure coolant supply 65 bar Laser control of tool availability Inductive button for temperature compensation on the electrospindle Tool Monitor Renishaw button type RMP 60 Rotoclear AR aspirator Machine preparation for hydraulic clamping (on the turntable) Automation of the plant

Datasheet

Request / Contact

Machining Center - Universal

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2274 · Machining Center - Universal

AXA - VHC 2-XTS/50 - - 2006 - Siemens 840 D

Technical details

Universal machining center for 5-axis simultaneous machining. Technical specifications: Traverse X/Y/Z 2360 x 600 x 800 mm Pendulum stroke with vertical spindle left/right 1160/700 mm Table clamping area 2750 x 600 mm with 4 T-slots Tool holder SK 50 Spindle speeds 30 - 4000 rpm. Equipment: CNC control Siemens 840 D with Shop Mill DIN ISO CNC rotary table type RTA 3-520 CNC swivel milling head infinitely variable positioning Tool changer with 26 tool places Chip conveyor Coolant system with high-pressure pump and belt filter system Coolant through spindle 20 bar Electric hand wheel Space requirements: Machine length 5650 mm + 1800 mm with chip conveyor Machine width 3500 mm plus control panel Machine height 3200 mm Machine without clamping vices and tool/holders.

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

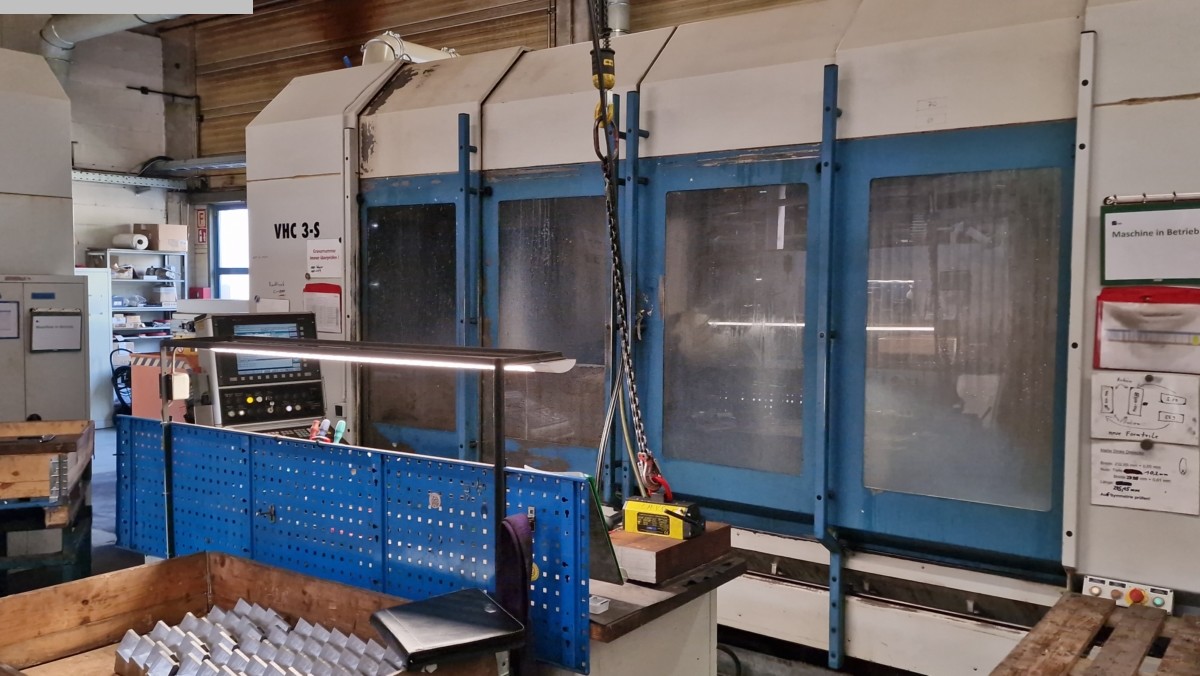

#1022-2273 · Machining Center - Universal

AXA - VHC-3-3000-S/50/E - - 2005 - Siemens 840 D

Technical details

Universal machining center for 5-axis simultaneous machining. Technical specifications: Traverse X/Y/Z 2940 x 700 x 850 mm Table size 3400 x 750 mm Pendulum stroke with vertical spindle left/right 1170/1170 mm Spindle speeds 30 - 6000 rpm. AC hollow shaft motor, power 45 kW at 40% ED Max. torque 286 Nm at 40% ED Tool holder SK 50 Equipment: CNC control Siemens 840 D with ShopMill CNC swivel milling head infinitely variable positioning directly programmable from X (-) 90° to X (+) 90° Locking via Hirth toothing Tapping without compensating chuck CNC rotary table, table diameter 630 mm Measuring system Heidenhain, direct linear Tool changer with 26 tool places Chip conveyor Coolant system with high-pressure pump and belt filter system Coolant through spindle 20 bar Space requirements: Machine length 5800 mm + 1700 mm with chip conveyor Machine width 3300 mm plus control panel Machine height 3200 mm

Datasheet

Request / Contact

Профіль торговця: Knops Werkzeugmaschinen

GmbH & Co. KG

Зв'язатися з трейдером

Кружки Веркезугмашінена

GmbH & Co. KG

Конрад-Цузе-штрассе, 5

40789 - Монхайм

Німеччина

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

GmbH & Co. KG

Конрад-Цузе-штрассе, 5

40789 - Монхайм

Німеччина

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Профіль Трейдера

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

Contact Trader

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Machine category

4-Säulenpresse - Hydraulisch · Abkantpresse - hydraulisch · Aufspanntisch · Aufspannwinkel · Bandsägeautomat - Horizontal · Bearbeitungszentrum - Horizontal · Bearbeitungszentrum - Universal · Bearbeitungszentrum - Vertikal · Blechrundbiegemaschine - 3 Walzen · Blechrundbiegemaschine - 4 Walzen · Brennschneidemaschine · CNC Dreh- und Fräszentrum · Doppelständerpresse - Hydraulisch · Drehbarer Aufspanntisch · Drehmaschine - zyklengesteuert · Fahrständerfräsmaschine · Fixatoren · Flachschleifmaschine - Horizontal · Flachschleifmaschine - Vertikal · Fräseinrichtung · Innenschleifmaschine · Karusselldrehmaschine - Doppelständer · Koordinatenmessmaschine · Kühlmittelanlage · Lagertechnik · Leit- und Zugspindeldrehmaschine · Magnetspannplatte · Messmaschine · Plan- und Spitzendrehbank · Planscheibe · Portal - Bearbeitungszentrum · Portalfräsmaschine · Roboter - Handling · Rundschleifmaschine - Außen · Rundtaktmaschine · Rundtisch · Rundtischflachschleifmaschine - 2 Spind. · Schleifmaschinenzubehör · Schweißdrehtisch - rund · Schwerdrehmaschine · Senkerodiermaschine · Stangenlademagazin · Tieflochbohrmaschine · Tuschierpresse · Werkzeug Voreinstellgerät · Werkzeugfräsmaschine - Universal · Werkzeughalter · Werkzeugschleifmaschine - Universal · Zahnrad-Abwälzfräsmaschine - vertikal · Zahnradschleifmaschine · Zubehör · Ölnebel-Abscheider ·