Engelfried Maschinentechnik GmbH - Stockist for used machines

Machinelist:

Boring and dowel inserting machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6480 · Boring and dowel inserting machine

PIZZI - Leimangabe f. Duebelbohrungen - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6349 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill m. Duebeleintreiben - - neu -

Technical details

Götzinger Power Drill in special version with dübelleim and press-in station With the Götzinger PowerDrill, you can choose: - Drill the front and long sides - Doweling of doors, seatings, fighters - The drilling patterns are freely programmable - You can: Grip handle and corner bearing, with quick-change Multi-spindle drilling heads - You can: lock casings, pusher and PZ as well as 3D tapes and drill - The machine has a horizontal and a vertical milling unit - A simple control lets you create drilling and milling programs, Save and recall POWER DRILL - drilling and milling machine Universal drilling machine for drilling olives, corner bearings, dowel work On the front and the front, milling, lock boxes, tapes, etc. Base in stable design, covered with sheet metal Table top 1800 x 200 mm Processing unit: X-axis - 500 mm working travel Y-axis - 100 mm Z axis - 105 mm 1 drilling unit horizontal (dowel drilling unit left) Drilling motor 380 V, 1,100 W Clamping chuck d = 8/10 4,000 - 11,000 rpm can be adjusted 1 drilling unit vertically from above - fixed Drilling motor 1.1 KW, 3,000 rpm Quick change of the drill head 1 drill head BKF 2/3, quick-changeable, (corner bearing) On the loose part, hardware according to customer requirements including drill replacement Control: electro-pneumatic with three axes NC positioning controller and integrated machine function Input via TFT display, 10 "color Machine complete, CE compliant, with 1 set of drilling tools Dübo je 1xd = 6,8,10,14 + 2 Roughing cutter d = 16, 1 milling cutter d = 20, ready for connection 1 drill head BKF 3, fast exchangeable for olives including drill bit Fitting according to customer requirements 2 drilling units 1 x horizontal for drilling from above (for tapes) 1 x vertical for dowel work, right Drilling motor 1.100 Watt, infinitely variable 4,000 - 11,000 rpm with collet chuck ER 20 2 Milling units for lock boxes 1 x horizontal for tapes, lock boxes 1 x vertically from above for PZ, pushers, tapes Milling motor 2.2 KW Speed ??adjustable 3,000 - 16,000 rpm Clamping tool holder ER 25 1 length stop right and left, working length 2.8 m NC-controlled When the length stop is used, the fixed stops are removed. Dimension: LxBxH = 2.50 x 1.50 x 2.20 m - Weight machine 850 kg PowerDrill LxBxH = 0,30 x 0,30 x 6,00 m - Weight length stop 100 kg 1 Dübelleim- and press-in station consisting of: - Swing conveyor for dowels with feed -Dübeleinpressstation -High pressure glue pump made of stainless steel with glue container - Full jet valve for precise glue application Exhaust nozzle Price for 1 dowel diameter The basic machine will be about 300 mm longer (Technical data according to manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6450 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill Typ BF 315 -Video- - - neu -

Technical details

Götzinger Power Drill Type BF 297 With the Götzinger PowerDrill you can, depending on the type and design: Griffoliven drill on the loose frame part or for finished wings, with multi-spindle drilling head, quick-change, also for milling of the lock case for WK 2 or intermediate gear Ecklager drill on loose frame part, with Mehrspindelbohrkopf, quick-change, corner-oriented over stop or custom made (tilt window) Drill vertically from above for fitting, pre-drill for clip on loose frame part Milling vertically from above for pushers, profile cylinders, 3-D hinges Horizontal drilling with 2 drilling units, different drilling diameters, Dowel drill front and long side, plywood / fighter, sprouts, Corner connection, front door etc. Milling horizontally for lock case / fitting etc. machine description Base frame in stable welded construction, linear guide for the X-axis Table top 3,000 x 200 mm 6 clamping cylinder pneumatic with auto. Ausweichhub 2 side stops for machining on the front side, manually swiveling in and out 2 longitudinal stops can be manually swiveled in and out Travel: X-axis - 3,000 mm working length Y-axis - 120 mm Z-axis - 105 mm Aggregate: 1 drilling unit (unit 1) vertically from above, drill motor 1,1 KW Speed ??1,500 - 12,000 rpm, 1 spindle, collet holder ER 20 1 Bohraggreagt (unit 2) vertically from above, drill motor 1,1 KW Speed ??3,000 rpm, with drill head quick change device 1 boring head BKF 3, olives, quick-change 1 boring head BKF 3/2 corner bearing, quick-change 1 milling unit (Agg.3) vertically from above, milling motor 2 KW, 1,500 - 16,000 rpm, collet holder ER 25 2 horizontal drilling units (Agg.4 and 5) 1.0 KW, 1.500 - 12.000 U / min, Collet holder ER 20 1 milling unit horizontal (Agg.3) 2.0 KW, 1.500 - 16.000U / min, Collet holder ER 20 Electro-pneumatic control with 3-axis control X, Y, Z NC positioning controller make B + R input via TFT display 10 " Machine complete with 1 set of drilling tools dm 6, 8, 10 and 12, 2 roughing carbide cutters HM dm 16, CE compliant, ready for connection Suction connection: 1 x dm 120 Power connection: 1 x 400 V, 16 amps Air connection: 1 x LW 9 mm OPTION: Longitudinal stops right / left with NC axis high / low programmatically, thus dimension input by folding / light measure possible, Dimension: LxWxH = 4.80 x 1.60 x 2.40 m - weight machine 1,500 kg (technical data according to manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6529 · Boring and dowel inserting machine

GÖTZINGER - Power Drill -300 Video - - - neu -

Technical details

1 NEW drilling and milling center Götzinger Power Drill 300 With the Götzinger PowerDrill you can, depending on the type and design: - Drill on the front and on the long side - Dowels of front doors, pegs, fighters - The drilling patterns are freely programmable - You can drill: handle slides and corner bearings, with quick-change multiple spindle - You can: Milling lock case, pusher and PZ as well as 3D belts and drill - The machine has a horizontal and a vertical milling unit - A simple control lets you create drilling and milling programs, save and call again Base frame in sturdy design, covered with sheet metal Table top 1800 x 200 mm Processing unit: X-axis - 500 mm working travel Y-axis - 0-120 mm Z-axis - 0-105 mm (above table) Horizontal aggregates: 1 horizontal drilling unit (dowel drilling unit left) -------------------------- Drilling motor 220 V, 1.1 kW Collet holder ER 25 4,000 - 11,000 rpm adjustable 1 milling unit horizontal for lock case -------------------------- Milling motor 2.2 kW Speed ??controllable 3,000 - 16,000 rpm Collet holder ER 25 1 horizontal drilling unit (dowel drilling unit right) -------------------------- Drilling motor 1100 W, infinitely variable 4,000 - 11,000 rpm, with collet holder ER 25 Vertical aggregates: 1 drilling unit vertical -------------------------- Drilling motor 1100 W, infinitely variable 4,000 - 11,000 rpm, with collet holder ER 25 1 boring unit vertical - with quick-change boring head -------------------------- Drilling motor 1,1 KW, 3,000 rpm Included: 1 boring head BKF 2/3, for corner bearing incl. Drill set, quick-change -------------------------- On loose item, drill assembly to customer fitting 1 boring head BKF 3, for olive incl. Drill set, quick-change -------------------------- On loose item, drill 1 cubo d = 25, 2 x dowel d = 10 1 milling unit vertical for lock case -------------------------- Milling motor 2.2 kW Speed ??controllable 3,000 - 16,000 rpm Collet holder ER 25 1 piece length stop right and left, usable length 2.7 m, NC controlled Control: electro-pneumatic with three-axis NC positioning controller and integrated machine function Input via TFT display, 10 "color Machine complete, CE-compliant, with 1 set of drilling tools, DÜBO each 1 x d = 6,8,10,12 + 2 roughing cutters d = 16, ready for connection Loading dimensions: Machine L x W x H = 2.50 x 1.50 x 2.30 m, weight 850 kg Length stop L x W x H = 6.00 x 0.30 x 0.30 m, weight 100 kg ------------------------------ Total price in above mentioned version, ex works: on request Plus freight and installation / instruction (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6838 · Boring and dowel inserting machine

GÖTZINGER - PowerDrill - - gebraucht -

Technical details

1 Götzinger Power Drill drilling and milling center ------------------------------------------------- Machine is FACTORY TESTED by Götzinger before delivery. Depending on the type and version, you can use the Götzinger PowerDrill to: - Drill on the front and long sides - Doweling of house doors, timbers, brackets - The drilling patterns are freely programmable - You can: drill handle olives and corner bearings, with quick-change ones Multi-spindle drilling heads - You can: mill lock cases, handles and PZ as well as 3D hinges drill - The machine has a horizontal and a vertical milling unit - A simple control allows you to create drilling and milling programs, save and access again and again Stable base frame, covered with sheet metal Table support 1800 x 200 mm Processing unit: X-axis – 500 mm useful travel Y axis – 0-120mm Z axis – 0-105 mm (above table) Horizontal aggregates: 1 horizontal drilling unit (dowel drilling unit on the left) -------------------------- Drill motor 1,100 W with collet holder 4,000 – 11,000 rpm continuously adjustable 1 horizontal milling unit for lock case -------------------------- Milling motor 2.2 kW Speed adjustable 3,000 - 16,000 rpm Collet holder ER 25 1 horizontal drilling unit (dowel drilling unit on the right) -------------------------- Drill motor 1,100 W with collet holder 4,000 – 11,000 rpm continuously adjustable Vertical aggregates: 1 vertical drilling unit -------------------------- Drill motor 1100 W, continuously adjustable 4,000 - 11,000 rpm, with collet holder ER 25 1 vertical drilling unit - with drill head quick-change device -------------------------- Drill motor 1.1 KW, 3,000 rpm Included: 1 drill head BKF 2/3, for corner bearings including drill set, quick-change -------------------------- On a loose item (fittings on request!) 1 drill head BKF 3, for olive, including drill set, quick-change -------------------------- On the loose item 1 vertical milling unit for lock case -------------------------- Milling motor 2.2 kW Speed adjustable 3,000 - 16,000 rpm Collet holder ER 25 1 piece of length stop right and left, usable length 3 m right/3 m left, NC controlled Control: electro-pneumatic with three axes NC positioning controller and integrated machine function Input via 10 inch touch panel Machine complete, CE compliant, with existing tools Loading dimensions: Machine L x W x H = 2.50 x 1.50 x 2.30 m, weight 850 kg Length stop L x W x H = 6.00 x 0.30 x 0.30 m, weight 100 kg -------------------------------- Total price in the above version, ex warehouse Oberkochen Pictures/video archive, show the same machine type (no original pictures available yet). (Technical information according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

Boring machine for fittings

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6265 · Boring machine for fittings

GÖTZINGER - OBM Plus - - neu -

Technical details

Olive drilling machine type OBM-PLUS (corner and shear bearing + handle olive drilling) Drilling unit vertical with drill head quick-change device Pneumatic feed via foot valve 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/400V, 50Hz, 1.1KW Machine without drilling head, without drilling tool ----------------------------------------------------- Basic price in the above version on request! Options with additional prices: -Drilling head BKF 3, 21.5 mm pitch, quickly changeable -1 set of drill bits for handles 2 dowel drills d=10 left 1 artificial drill d=25 -Drill head BKF 2/3 quick-change drill 2/3 spindles for corner bearings on the loose frame part (Sigenia, Maco, Roto, Winkhaus, GU) complete with stop system with 2 folding stops -Drill 2 cylinder head drill bits for corner bearing Special accessories: -folding stops -Stop system for central drilling -Landing gear We would be happy to send you the price list with all options on request. (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6264 · Boring machine for fittings

GÖTZINGER - OBM 1 - - neu -

Technical details

Olive drilling machine type OBM 1 Standard version (only handle olive drilling) Drilling unit vertical complete with drill head BKF 3, 21.5 mm pitch Drill mount M 10, cyl. right/left Pneumatic feed via foot valve Spring-loaded hold-down devices Stop system 2200 mm Total length with 10 folding stops adjusted to fitting 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/380V, 50Hz, 1.1KW Machine complete, but without drilling tool ----------------------------------- Price in the above version on request! Options with extra charge: -1 set of drills consisting of: 2 dowel drills d = 10 left 1 artificial drill d = 25 (or according to choice or manufacturer's fitting) -folding stops -Stop system for central drilling -Landing gear -Roller conveyor right/left 1.5 m, 200 mm wide complete with 4 rolls each - Packing 1 box Packaging 1 pallet with foil We will be happy to send you the complete price sheet on request! (Technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2714 · Boring machine for fittings

HESS - Bohrstation Ecklager+ Olive - - gebraucht -

Technical details

Hess corner bearing and olive drilling machine ---------------------------------- - Stable base frame as a support wall - precise support made of abrasion-resistant and dimensionally stable plastic for frames and sashes up to 100 mm thick - Corner bearing and olive drilling in one machine and in one Drilling unit - easy and comfortable vertical work - easy handling - no templates, minimal Time required for safe workpiece positioning, Guarantee for exact and precise holes - 2 clamping cylinders for immovable fixation of sashes or frame adjustable to different wood thicknesses - Lateral stop in the rebate for the corner bearings - Ergonomically arranged stop system for olive drilling with 14 hinged stops and additional color markings - fixed stop system for borehole - height determination when changing Corner camp to Olive - automatic drilling depth sensing for corner bearing and olive - Drilling unit with quick-change chuck for the various tools for corner bearing and olive - Tool change “in the blink of an eye” - automatic program flow - clean work thanks to effective suction - Small space requirement and mobile thanks to swivel/brake casters Electrical equipment according to VDE Electrical connection: 0.55 kW, 400 volts, 3/N, PE, 50 Hz Pneumatic connection: R 1/4", min. 4 bar, max. 8 bar Air consumption: 7 NL / cycle Suction connection piece: 1 x 80mm diameter Suction speed: 25 m/sec. External dimensions/floor dimensions/space requirements: Width: 2600mm Height: 1250mm Depth: 800mm Support height: 300 mm Weight: 310kg Paint finish: RAL 7030 stone gray with 1018 zinc yellow ---------------------------------- (Technical description according to the manufacturer - no guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2698 · Boring machine for fittings

GÖTZINGER - OBM-Plus - - gebraucht -

Technical details

Corner bearing and olive drilling machine Götzinger OBM-PLUS Vertical drilling unit with quick-change device Pneumatic feed via foot valve 1 adjustable backstop 2 swiveling workpiece supports 1 machine stand complete with shelf Left and right roller conveyor each 1.5 m, 200 mm wide, 4 rollers each 220/380V, 50Hz, 1.1KW 1 drill head BKF 3, 21.5 mm pitch, quick-changeable Drill mount M 10, cyl. right/left complete with stop system 2200 mm long Total length with 12 folding stops adjusted to a constant grip dimension (olive drilling) Consisting of: 2 dowel drills d=10 mm 1 artificial drill d=25 mm 1 drill head BKF 2/3 quick-change drill 2/3 spindles for corner bearing on the loose frame part. Hardware Roto- alternative on request Complete with stop system with 2 folding stops Drill mount: M 10 right/left 2x7 mm and 34 mm (Technical description according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6841 · Boring machine for fittings

GÖTZINGER - OBM Plus - - gebraucht -

Technical details

Olive drilling machine type: OBM-Plus Special version (corner and scissor bearing + handle olive drilling) --------------------------------- Vertical drilling unit with quick-change device Pneumatic feed via foot valve 1 adjustable back stop 2 swiveling workpiece supports 1 machine stand complete with shelf 220/380V, 50Hz, 1.1KW Machine complete, but without drilling tools Drill head BKF 3, 21.5mm pitch, quick-changeable Drill holder M 10, cyl. right/left complete with stop system 2200 mm long Total length with 10 folding stops set to a constant grip size (for handle olives) Drill head BKF 2 can be changed quickly 2 spindles for corner bearings drill on the loose frame part complete with stop system with 2 folding stops Drill consisting of 2 pieces of dowel drills d = 12 mm left 1 piece of artificial drill d = 25 mm right Drill 2 cylinder head drills for corner bearings Stop system for center drilling landing gear Roller conveyor right/left 1.5 m, 200 mm wide complete with 4 rolls each 2 additional stops for picking the fighter groove Fitting: Siegenia Titan AF latest version with 30mm double pot Installation dimensions: 3600 x 800 x 1900 mm -------------------------------- Price of the above machine on request! -------------------------------- Option: Prices for other drilling heads (other hardware) on request (Technical information according to the manufacturer - no guarantee!

Datasheet

Request / Contact

CNC processing centre windows & doors

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

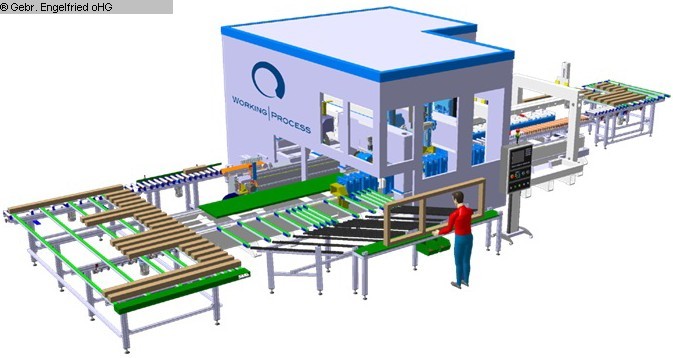

#1305-5602 · CNC processing centre windows & doors

WORKING PROCESS - Fensteranlage -Video- - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6520 · CNC processing centre windows & doors

MASTERWOOD - Project385 Innenausbau,Fenster - - neu - Beckhoff CNC

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6360 · CNC processing centre windows & doors

WORKING PROCESS - Logos Life Evo XS Video - - neu - Siemens 840d

Technical details

Working Process Logos Life Evo XS 2345 ------------------------------- Vollautomatisches CNC-Fensterfertigungsanlage mit automatischer Be- und Entladung. 2 Portale mit 3 Frässpindeln mit 4- und 5-Achstechnologie CNC-gesteuerter Manipulator für Werkstückpositionierung mit 16 Stück Doppelzangen 8 Stück komplett unabhängige Werkstückspanner für höchste Felxibilität und Produktivität 128 Werkzeugplätze NEU: Working Process baut nun auch 1-spindlige Anlagen mit bewährter Technologie für kleinere Betriebe! Nebenstehend finde Sie aktuelle Videos dieser Baureihe.

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6511 · CNC processing centre windows & doors

MASTERWOOD - 4 Win mit Beladung - Video - - - neu -

Technical details

CNC machining center MASTERWOOD 4 WIN with automatic loading and unloading -------------------------------------------- Specially designed for a rational and flexible wooden window u. door production HIGHLIGHTS: - Various tool magazines for optimal tooling - Simultaneous feeding with up to 6 workpieces - patented clamping system for optimum machining of workpieces - CNC controlled work table with automatic positioning of the beams and Stretcher - Automatic reclamping for changing between external and internal profiling - INTEGRATED windowing software, i. Machine does not have to (but can Of course) be controlled from the office with external industry software. - powerful engine with 19.2 kW HSK-63 E - Loading and unloading conveyor Ask for a quote and see for yourself unbeatable value for money! VIDEO from the machine attached! At the side you will find the techn. Description of the machine as a PDF document. We would be happy to make your used machine one take reasonable price in payment! (technical information according to the manufacturer - without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6428 · CNC processing centre windows & doors

MASTERWOOD - Project 385 WL,Allround, Video - - neu - Beckhoff CNC

Technical details

CNC machining center Masterwood Project 385 WL, NEUMASCHINE The all-rounder for Windows, round arches and doors interior Post and beam 5-axis machining of all kinds Detailed description in the adjacent PDF file! HIGHLIGHTS: - Working range: X = 5150 mm; Y = 1500 mm; Z = 200 mm - 1 pc. 5-axis high-performance spindle, 16 kW, double bearing with HSK 63 F recording - fixed drill head with 19 spindles with 7 individually retrievable vertical spindles X-direction with 6 individually retrievable vertical spindles Y-direction with 2 double horizontal spindles X-direction and 1 double horizontal boring spindle in the Y direction Saw unit integrated in drill head - Carousel tool changer with 22 places and 102 mm grid spacing - Carousel tool changer with 16 places and 102 mm grid spacing - linear 4-fold tool magazine - Special clamps for straight window and door parts - special clamps for round window and door elements - 24 pcs. Vacuum clamps for internal installation - Vacuum pump - Chip conveyor belt - extensive design software for interior design, panel processing as well as f. Windows and doors: Masterwork: 2D-Wop for standard application panel processing / interior fitting with Additional function Lamello connection Master 3D Level 2: for more complex edits, optionally also expandable for 5-axis fully interpolating MasterWindow: Integrated window and door design software i.e. Machine does not have to (but of course) with external industry software be controlled. VIDEO shows production of 4 sash parts in one clamping Complete machining including glazing bead production. Corner joint hybrid. Of course, all common corner joints on the machine producible. OTHER OPTIONS ON REQUEST! We are also happy to offer you suitable tools for the machine. (Techn.According to the manufacturer - without guarantee!)

Datasheet

Request / Contact

Cross cut saw

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2691 · Cross cut saw

SALVAMAC - Classic 50 mit Salvastop Video - - Vorfuehrmaschine -

Technical details

SALVAMAC CLASSIC 50 – The semi-automatic miter saw with SALVASTOP 100 - electronic length stop/slider -------------------------------------------------- - New machine from our demonstration room, Bj. 2022 Pos. 1: Classic 50 under table miter saw -------------------------------------------------- - Maximum cutting area: 220x125/ 260x100/285x80/310x50 mm. When cutting boards that are on top of each other, h max. 100 mm. The structure is made entirely of thick-walled and reinforced full-surface painted steel. Solid floor mounting system with flanged steel feet for the mounting hole. Bimanual safety cut control in ergonomic position. Motor power of the saw motor 5.5 kW. Adjustable cutting speed via a pneumatic controller. Maximum system for weight balancing and longevity. Shock absorbing system. Independent pneumatic adjustment options to adapt to different types of processing. Durable and easily replaceable saw blade adjustment bar. HM circular saw blade, diameter 500 mm, Z=108. Pneumatic upper workpiece clamping press with electro-pneumatic control. Presser movement system using new ball bearings with double dust protection and automatic lubrication system. CE compliant electrical system. The CE models must come standard with at least 1 meter long support plates at the inlet and outlet. Technical specifications: ------------------------------- Saw cross-section max. mm. 220x125, 260x100, 285x80, 310x50 Saw blade motor power: 5.5 kW Saw blade diameter: 500 mm Saw blade type: HM Z=108 Saw blade rotation speed: 2800 rpm Air consumption per cycle: 7 Nl Intake manifold: 1 - 120 mm / 1 - 100 mm Air pressure: 6 - 8 bar Voltage: V 400/50Hz 3-phase Worktop height: 900 mm +- 20 mm Colour: Ral 7035 - Ral 1007 Pos. 2: Salvastop 100 electronic length stop -------------------------------------------------- - - Working method: 2 modes 1 x stop (length stop moves to the specified length) and 1 x slide (several lengths are processed one after the other at the push of a button) - with servo drive - Ram speed: up to 60 m/min - slider length 600 mm - with a 7'' touch display - maximum weight of logs that can be pushed - up to 100 kg - USB connection COMBO_50 - 6400/7000 - Roller conveyor with guide to the right of the saw. Painted steel frame with galvanized castors. Load capacity 230 kg, diameter 60 mm, spacing 250 mm, width 320 mm. 3 m. - 6400/7000 SalvaStop 100 to the left of the saw. Working length 6.4 m. Total length 7.0 m. With table top 7 m. Width 320 mm. Demonstration machine additionally equipped with: UP & DOWN FRONT PROTECTION Movable instead of rigid front protection. The guard rises during cutting to ensure safe working conditions. Loading and unloading wood is simplified with the downward-facing guard. The system has another special, secured pneumatic system with linear guidance, which impresses with top quality and cutting-edge technology. SOFTWARE LINK FILES Preparation for data import via a Salvamac file template in CSV format. ------------------------------- Total price demonstration machine from stock 73447 Oberkochen: on request! ------------------------------- More options like longer/shorter inlet/outlet, Stop systems on request! (technical data according to the manufacturer without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6846 · Cross cut saw

SALVAMAC - Legend 550 - - neu -

Technical details

SALVAMAC Legend 550 the semi-automatic chop saw -------------------------------------------------- - Maximum cutting area 220x150/330x50 mm (When sawing stacked boards, note: rear stop height 100 mm) The structure is made entirely of sturdy, thick-walled steel, which is painted throughout and reinforced. A solid one Floor mounting system is equipped with flanged steel feet, to ensure secure attachment. The two-hand control is ergonomically positioned for comfort and efficient operation. Engine power of the saw motor 7.5 kW. The cutting speed is adjustable via a pneumatic controller, to enable precise adjustment. The system also has a Shock-absorbing system to minimize vibrations and ensure worker safety to improve. HM circular saw blade, diameter 550 mm, Z=96. The upper pressure hood has an electro-pneumatic control for precise operation. The pressure hood movement system is innovative Ball bearings operated with double dust protection and automatic lubrication system, which ensures smooth functionality. In addition, the electrical system is compliant with CE standards. CE models are standard with at least 1 meter long inlets and outlets (undriven rollers or flat table) to facilitate operation optimize and meet security standards. Technical data: ------------------------------- Saw cross section: 220x150/330x50 mm Saw blade motor power: 7.5 kW Saw blade diameter: 550 mm Saw blade type: HM Z=96 Saw blade rotation speed: 2800 rpm Air consumption per cycle: 7 Nl Intake port: 1 x 120 mm / 1 x 100 mm Air pressure: 6 - 8 bar Voltage: V 400/50 Hz 3 phase Worktop height: 900 mm +- 20 mm Color: Ral 7035 ------------------------------- Total price ex works: on request! ------------------------------- Options like: - Inlet/outlet with undriven rollers/flat table - Mechanical or pneumatic stops - Electronic length stop / slider Salvastop (Combo series) - Movable front protection and more on request! ------------------------------- (technical data according to the manufacturer without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

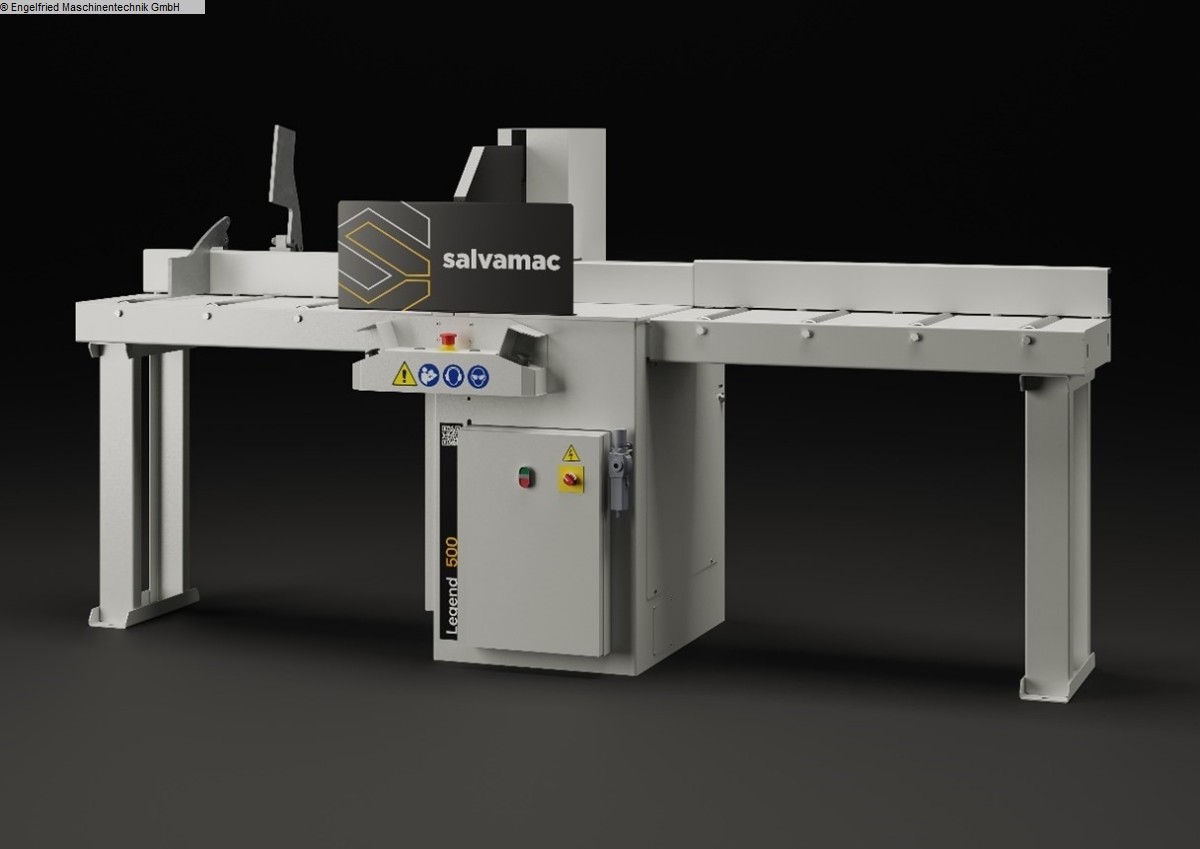

#1305-6845 · Cross cut saw

SALVAMAC - Legend 500 - - neu -

Technical details

SALVAMAC Legend 500 fast semi-automatic chop saw -------------------------------------------------- - Maximum cutting area Option A: 220x125/310x50mm Option B: 350x80/375x50mm (When sawing stacked boards, note: rear stop height 100 mm) The structure is made entirely of sturdy, thick-walled steel, which is painted throughout and reinforced. A solid one Floor mounting system is equipped with flanged steel feet, to ensure secure attachment. The two-hand control is ergonomically positioned for comfort and efficient operation. Engine power of the saw motor 5.5 kW. The cutting speed is adjustable via a pneumatic controller, to enable precise adjustment. The system also has a Shock-absorbing system to minimize vibrations and ensure worker safety to improve. HM circular saw blade, diameter 500 mm, Z=108. The upper pressure hood has an electro-pneumatic control for precise operation. The pressure hood movement system is innovative Ball bearings operated with double dust protection and automatic lubrication system, which ensures smooth functionality. In addition, the electrical system is compliant with CE standards. CE models are standard with at least 1 meter long inlets and outlets (undriven rollers or flat table) to facilitate operation optimize and meet security standards. Technical data: ------------------------------- Saw cross section: Option A: 220x125/310x50mm Option B: 350x80/375x50mm Saw blade motor power: 5.5 kW Saw blade diameter: 500 mm Saw blade type: HM Z=108 Saw blade rotation speed: 2800 rpm Air consumption per cycle: 5 Nl Intake port: 1 x 120 mm / 1 x 100 mm Air pressure: 6 - 8 bar Voltage: V 400/50 Hz 3 phase Worktop height: 900 mm +- 20 mm Color: Ral 7035 ------------------------------- Total price ex works: on request! ------------------------------- Options like: - Inlet/outlet with undriven rollers/flat table - Mechanical or pneumatic stops - Electronic length stop / slider Salvastop (Combo series) - Movable front protection and more on request! ------------------------------- (technical data according to the manufacturer without guarantee!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6847 · Cross cut saw

SALVAMAC - Legend 600 - - neu -

Technical details

SALVAMAC Legend 600 the semi-automatic chop saw -------------------------------------------------- - Maximum cutting area 420x150/520x100/610x30 mm (When sawing stacked boards, note: rear stop height 100 mm) The structure is made entirely of sturdy, thick-walled steel, which is painted throughout and reinforced. A solid one Floor mounting system is equipped with flanged steel feet, to ensure secure attachment. The two-hand control is ergonomically positioned for comfort and efficient operation. Engine power of the saw motor 9.2 kW. The cutting speed is adjustable via a pneumatic controller, to enable precise adjustment. The system also has a Shock-absorbing system to minimize vibrations and ensure worker safety to improve. HM circular saw blade, diameter 600 mm, Z=132. The upper pressure hood has an electro-pneumatic control for precise operation. The pressure hood movement system is innovative Ball bearings operated with double dust protection and automatic lubrication system, which ensures smooth functionality. In addition, the electrical system is compliant with CE standards. CE models are standard with at least 1 meter long inlets and outlets (undriven rollers or flat table) to facilitate operation optimize and meet security standards. Technical data: ------------------------------- Saw cross section: 420x150/520x100/610x30 mm Saw blade motor power: 9.2 kW Saw blade diameter: 600 mm Saw blade type: HM Z=132 Saw blade rotation speed: 2750 rpm Air consumption per cycle: 7 Nl Intake nozzle: 2 x 140 mm Air pressure: 6 - 8 bar Voltage: V 400/50 Hz 3 phase Worktop height: 900 mm +- 20 mm Color: Ral 7035 ------------------------------- Total price ex works: on request! ------------------------------- Options like: - Inlet/outlet with undriven rollers/flat table - Mechanical or pneumatic stops - Electronic length stop / slider Salvastop (Combo series) - Movable front protection and more on request! ------------------------------- (technical data according to the manufacturer without guarantee!)

Datasheet

Request / Contact

Cross rung milling cutter

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

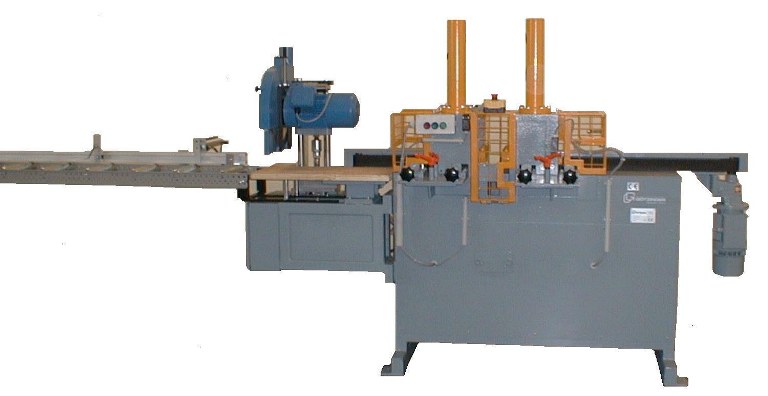

#1305-5827 · Cross rung milling cutter

STEGHERR - KSF-mini - - neu -

Technical details

Cross rung milling machine STEGHERR TYPE KSF-mini including standard stop with 2 sliding stops, without tools With the KSF-mini, all of those that occur in practice can be used Crossbar connections can be made quickly and precisely. The Precise execution is achieved by having the workpiece in one Clamping is machined on three sides. The tool is driven by two three-phase motors; the tension of the Workpieces pneumatically. The profile cutter is designed for the web width. The saw blades that... If you carry out flattening, spacer rings are used to match the dimensions of the Profile milling cutter adjustable. The swivel device is free of play. The machine is designed for a maximum workpiece cross section of 56 x 46mm. Voltage Europe: 400V(+/-10%)/3Ph/50Hz, USA: 440V(+/-10%)/3Ph/60Hz Other voltages on request. Operating instructions in German or English. Table base €890.00 Foot switch €600.00 Adjustment optics €110.00 Profile milling cutter in HM-Wepla version, available for selection: Ø 5,7,9,11,13 mm. Price per piece €545.00 1 set of replacement insert knives for profile milling cutters (=10 pieces) €165.00 HM saw blade, price €150.00 per piece (For a web of e.g. 10 mm, 3 saw blades are required) Setting the machine to the tools provided by the customer, price €580.00 per individual tool Packaging in a crate (suitable for land transport) €590.00 Packaging shrink-wrapped on a pallet (only within Europe, not for air freight) €310.00 Pricing ex works, unpacked, uninsured, for delivery within Germany plus the VAT valid at the time of delivery. (all technical information according to the manufacturer, without guarantee!)

Datasheet

Request / Contact

Double mitre saw

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6740 · Double mitre saw

RAPID - DGL 200 E - - neu - ja

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6738 · Double mitre saw

RAPID - DGS 200 - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6739 · Double mitre saw

RAPID - DGL 200 M - - neu -

Technical details

Datasheet

Request / Contact

Finger jointing line

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5204 · Finger jointing line

GOETZINGER - Manuelle Keilzinkenanlage - - neu -

Technical details

Datasheet

Request / Contact

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

Contact Trader

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Machine category

Abrichthobelmaschine · Absauganlage · Band- und Profilschleifmaschine · Bandsäge · Beschlagcenter · Bohr- und Dübeleintreibmaschine · Breitbandschleifmaschine · Clipsetzer fuer Holz-Alufenster · CNC-Bearbeitungszentrum · CNC-Bearbeitungszentrum Fenster u. Türen · Dickenhobelmaschine · Doppelgehrungssäge · Dreh- und Kipptisch · Druckbalkensäge · Ecklager- und Olivenbohrmaschine · Einzelholzschleifmaschine · Entstauber · Fensteranlage · Fensterlackieranlage · Fensterwerkzeuge · Fertigungslinie · Formatkreissäge · Fräsmaschine · Furnierklebegerät · Furnierpresse · Füge- und Feinschnittmaschine · Glasleistensäge · Kantenschleifmaschine · Kapp- und Gehrungssäge · Keilzinkenanlage · Klammergeräte · Kombinierte Abricht- und Dickenhobelmasc · Kommissionswagen · Kompressor · Kreuzsprossenfräse · Lamellierpresse · Leimauftragsmaschine · Leimgerät · Längskreissäge · Längsschnittkreissäge · Minizinkenpresse · Montagestation · Olivenbohrmaschine · Optimierungskappsäge · Plattensägen vertikal · Profilwagen · Rahmen- und Langlochbohrmaschine · Rahmenpresse · Rollenbahn · Rundbogenfräsgeräte · Schleifmaschine · Schwenkfräsmaschine · Transportanlage · Transportwagen · Umfälzautomat · Untertischkappsäge · Verglasungs- und Kontrollpresse · Verleimstern · Vierseitenhobelmaschine · Werkstückrückführung · Werkzeug-Reinigungsgeräte · Zapfenschneid- und Schlitzmaschine · Zerspanen ·