Vacuum-Lifter

Machinelist: Vacuum-Lifter

Mandrel tube bending machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6387 · Mandrel tube bending machine

ERCOLINA - Mega Bender 030 / Top 030 - - 2014 -

Technical details

- Powerful mandrel bending machine up to 2 "gas pipe (60.3mm) in semi-automatic design (6000 mm pipe slide length) - Electromechanical drive of the bending axis - hydraulic clamping - mandrel feed / extract - 30 programs x 9 bending angle + correction angle

- Plum & Partner Werkzeugmaschinen GmbH

- Winkelstraße 32

- 32257 Bünde

- Deutschland

-

+49 05223 574444

+49 5223188330 -

info@plum-maschinen.de

www.plum-maschinen.de

#1082-12117 · Mandrel tube bending machine

TRANSFLUID - DB 628 ST / SPS - - 1996 - IPU 20

Technical details

Semi-automatic electro-hydr. mandrel tube bending machine with PLC control for 20 angles and display in the control panel for bending angle specification, angle detection and angle measurement via absolute value encoder, autom. tool plate reset, Turning device with digital display, hydr. quick chuck, aut. Mandrel lubrication, adjustable length stops. Operating modes: MANUAL and semi-automatic. Control buttons: hydraulics on / off, operating mode selection, clamp to / on, clamp forward / backward, mandrel forward / backward, bending forward / backward /, locking forward / backward, mandrel lubrication, turning device forward / backward, plate reset, length stop forward, emergency stop. The machine comes from a prototype construction and was only used a little until 2000. After that, the machines of this department were sold. However, the purchaser did not use the pipe bending machine and therefore it has only stood in the warehouse and has not worked since then. Please notice that the price of a new machine today is over € 60.000,--. Machine dealer with own stock of 1600 m².

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-02675 · Mandrel tube bending machine

SCHWARZE-WIRTZ - CNC 25 MR - - 1994 -

Technical details

- Hans Klein Werkzeugmaschinenhandel GmbH

- Im Mühlgut 2-4

- 77815 Bühl

- Deutschland

-

0049 (0) 7223 9617-0

0049 (0) 7223 58512 -

info@klein-werkzeugmaschinen.de

www.klein-werkzeugmaschinen.de

#1052-01220 · Mandrel tube bending machine

SCHWARZE-WIRTZ - PERFEKT WE 40 D - - 1977 -

Technical details

- with 8-pos. bending angle pre-selection - crawler gear control - positioning device by hand - tube twist device Following bending tools are with the machine: - ø 10 mm, radius 27,5 mm - ø 12 mm, radius 35 mm - ø 12 mm, radius 56 mm - ø 15 mm, radius 35 mm - ø 15 mm, radius 57,5 mm - ø 18 mm, radius 35 mm - ø 18 mm, radius 59 mm

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-1081 · Mandrel tube bending machine

ERCOLINA - Ercobender EB76 CNC V7S - - -

Technical details

FST clamping system (Patented) 6 programmable axes: carriage mobement (Y1 axis), bending plane rotation (B axis), bending angle (C axis), pressure die movement (X2 axis), booster (Y2 axis) and hydraulic mandrel movement (Y3) Touch screen control with 3D display of the tube Anti collision system tube/machine, tube/floo, tube/external elements and tube/equipment Importing files in iges and dxf format (optional) Integrated Wi-Fi FURTHER MANDREL LENGTHS ON REQUEST

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-2040 · Mandrel tube bending machine

ERCOLINA - TB80-A/P80NC-4 - - -

Technical details

Three-phase NC electric-hydraulic mandrel bending machine up to 76 mm with 1 controlled axis (bending axis C) New TCPlus control • 7” colour touch screen • Icons for ease use • Automatic mode, manual mode, programming mode • Advanced OFFSET function • Easy language change • Auto-tuning of the main machine components • Programmable bending speed for each single bend of the program • Unlimited programs possibility (USB port) • Every program can contain up to 30 different bends • Available extensions of 2 meters each (optional) • Tie bar (optional - art. TB80-TI)

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-969 · Mandrel tube bending machine

ERCOLINA - Topbender TB 050 PT A3/H48 - - -

Technical details

With mandrel 3 m length Can be used with or withoud mandrel Two bending speeds Programmable bend sequencing and mandrel retraction Independent clamp and pressure die adjustment Micrometer wiper die adjustment Auxiliary system for stabilizing the hydraulic slide pressure Quick tool change system With pneumatic material clamping and DRO system for linear and rotational positioning ALTERNATIVELY: model with mandrel 6 m length price on request

Datasheet

Request / Contact

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-1075 · Mandrel tube bending machine

ERCOLINA - Megabender MG 030 PT A3/H76 - - -

Technical details

with mandrel 3 m length FST closure system (Patented) with auxiliary system for stabilizing the hydraulic pressure of the slide Programmable C-axis bending Positioning of the 2-axis manual spindle carriage (Y1=Feed and B=Rotation) with high resolution encoder and standard adjustable mechanical stops Multifunction control keyboard integrated in the machine body with microprocessor control with multifunctional menu 30 programs of 9 bends each can be memorized Screen for digital display for carriage feed (Y1 Axis) and rotation (B Axis) External pressure gauges for easy setting of the system and closing pressure Variable bending speed up to 4 rpm (Inverter versions) Pneumatic chuck ALTERNATIVELY: model with mandrel length 1,5 / 4 / 6 mm

Datasheet

Request / Contact

Vacuum-Lifter

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

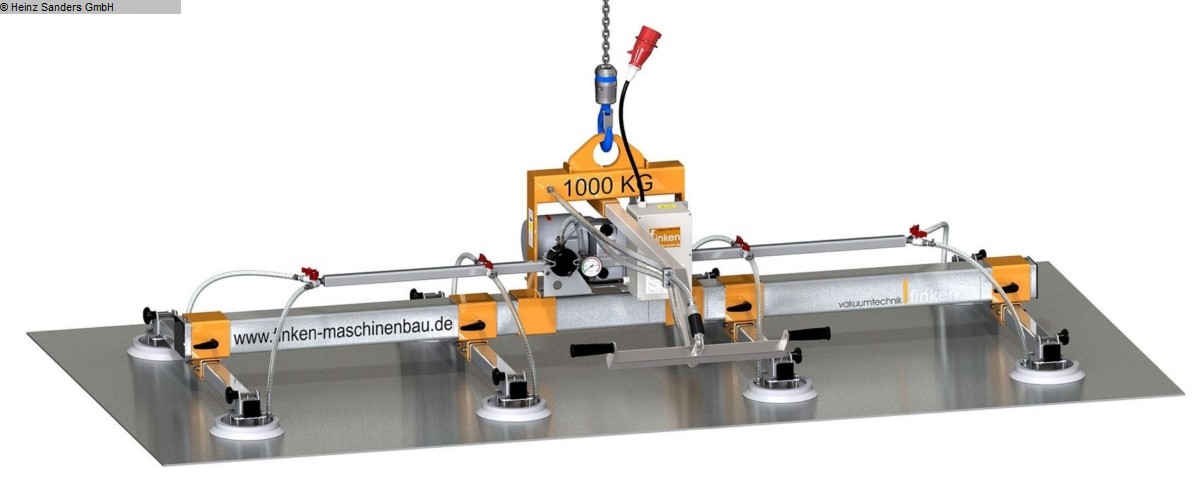

#1125-2530003 · Vacuum-Lifter

FINKEN - VH 8-1000 - - NEU -

Technical details

Vacuum lifter VH 8-1000 for the horizontal transport of smooth, dry and airtight panels. Robust supporting structure made of steel, painted in RAL 2000 with low Own weight. consisting of: - 1x galvanized longitudinal beam with a length of 2,400 mm - 4x galvanized crossbeams with a length of 1,000 mm - 8x Springy, articulated and adjustable suction cup holders - 8x suction cups Ø 280 mm, in case of wear the seal can be separated whose metal supports can be changed inexpensively and without tools - 8x ball valves to switch off individual suction cups, thus also smaller formats can be lifted without having to move suction cups or traverses. - 1x spiral connection cable small helix: * with an extension length of 3,500 mm, designed as an extension cable with CEE plug and coupling. * is routed to the lifting device next to the load chain. - Low-maintenance, very high-quality, oil-lubricated rotary vane vacuum pump with a Suction power of 21 m³/h and an ultimate vacuum of 98% (20 mbar). - Electrical connection: 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) and CEE plug (16 A). Integrated into the control with isolating transformer (necessary if the vacuum lifter is connected via the crane trolley and this has no neutral conductor) - Operating handle can be extended to 1,000 mm from the center of the traverse. Sturdy sheet metal bag for your crane control incl. at no extra charge. - Operation "suction / release" using manual slide valve: The wear-free and very robust manual slide valve ensures safe Suction and release after pressing the release button. (twice loosening according to EN 13155) - Control and safety device for vacuum lifters: * Robust control box. * Contactor circuit for the vacuum pump. * Safety warning device with audible alarm. * Vacuum gauge with danger zone indicator. * Large vacuum storage tank with safety check valve * Double actuation when releasing the load. - Fine dust filter to protect the vacuum pump - Detailed and easy to understand documentation. One year warranty against material and manufacturing defects One-shift operation (without wearing parts). Initial test UVV 18, VBG 9a with CE declaration of conformity - according to EN 13155 - Packing for truck transport.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6305 · Vacuum-Lifter

CARMITECH - Solid Swing 3015 - - 2017 (NEU) -

Technical details

** Year of construction 2017 - NEW - exhibition machine ** In contrast to most vacuum systems / lifting systems, the SOLIDswing constructed so that the recorded disk always remains vertical when it is recorded vertically. The plate can without precise positioning of the Suction cups are accommodated and this is independent of the balance Way of working much faster and safer than with conventional manual ones Vacuum systems.

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

#1008-9803043 · Vacuum-Lifter

TURBO VACUUMENTATION - SWL 2800 KGS - - 2014 -

Technical details

** New price ~ 11.000 euros ** Special price on request Furnishing: - Suspension frame with suspension eye for hanging in a hoist hook - Manipulating handle with easy-to-grip manual slide valve - main traverse (length: 2000 mm) - Dimensions "suction plates" .. 2x 720x720 mm .. 1x 615x615 mm - sliding suction plates - "BECKER" vacuum pump * Machine link : http://mhp.logotech.de/hpm/v7/Datenblatt/datenblatt.php?machineno=1008-9803043

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2530001 · Vacuum-Lifter

FINKEN - VH 6-250 - - (NEU) -

Technical details

Vacuum lifter VH 6-250 for the horizontal transport of smooth, dry and airtight panels. Robust supporting structure made of steel, painted in RAL 2000 with low Own weight. consisting of: - 1x galvanized longitudinal beam with a length of 2,400 mm - 3x galvanized crossbeams with a length of 1,000 mm - 6x Springy, articulating and adjustable suction cup holders - 6x suction cups Ø 215 mm, the seal can be separated in case of wear whose metal supports can be changed inexpensively and without tools - 6x ball valves to switch off individual suction cups, thus also smaller formats can be lifted without having to move suction cups or traverses. - 1x spiral connection cable small helix: * with an extension length of 3,500 mm, designed as an extension cable with CEE plug and coupling. * is routed to the lifting device next to the load chain. - Low-maintenance, very high-quality, dry-running rotary vane vacuum pump a suction capacity of 8 m³/h and a final vacuum of 85% (150 mbar) - Electrical connection: 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) and CEE plug (16 A). Integrated into the control with isolating transformer (necessary if the vacuum lifter is connected via the crane trolley and this has no neutral conductor) - Operating handle can be extended to 1,000 mm from the center of the traverse. Sturdy sheet metal bag for your crane control incl. at no extra charge. - Operation "suction / release" using manual slide valve: The wear-free and very robust manual slide valve ensures safe Suction and release after pressing the release button. (twice loosening according to EN 13155) - Control and safety device for vacuum lifters: * Robust control box. * Contactor circuit for the vacuum pump. * Safety warning device with audible alarm. * Vacuum gauge with danger zone indicator. * Large vacuum storage tank with safety check valve * Double actuation when releasing the load. - Fine dust filter to protect the vacuum pump - Detailed and easy to understand documentation. One year warranty against material and manufacturing defects One-shift operation (without wearing parts). Initial test UVV 18, VBG 9a with CE declaration of conformity - according to EN 13155 - Packing for truck transport.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2530002 · Vacuum-Lifter

FINKEN - VH 6-500 - - (NEU) -

Technical details

Vacuum lifter VH 6-500 for the horizontal transport of smooth, dry and airtight panels. Robust supporting structure made of steel, painted in RAL 2000 with low Own weight. consisting of: - 1x galvanized longitudinal beam with a length of 2,400 mm - 3x galvanized crossbeams with a length of 1,000 mm - 6x Springy, articulating and adjustable suction cup holders - 6x suction cups Ø 215 mm, the seal can be separated in case of wear whose metal supports can be changed inexpensively and without tools - 6x ball valves to switch off individual suction cups, thus also smaller formats can be lifted without having to move suction cups or traverses. - 1x spiral connection cable small helix: * with an extension length of 3,500 mm, designed as an extension cable with CEE plug and coupling. * is routed to the lifting device next to the load chain. - Low-maintenance, very high-quality, dry-running rotary vane vacuum pump a suction capacity of 8 m³/h and a final vacuum of 85% (150 mbar) - Electrical connection: 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) and CEE plug (16 A). Integrated into the control with isolating transformer (necessary if the vacuum lifter is connected via the crane trolley and this has no neutral conductor) - Operating handle can be extended to 1,000 mm from the center of the traverse. Sturdy sheet metal bag for your crane control incl. at no extra charge. - Operation "suction / release" using manual slide valve: The wear-free and very robust manual slide valve ensures safe Suction and release after pressing the release button. (twice loosening according to EN 13155) - Control and safety device for vacuum lifters: * Robust control box. * Contactor circuit for the vacuum pump. * Safety warning device with audible alarm. * Vacuum gauge with danger zone indicator. * Large vacuum storage tank with safety check valve * Double actuation when releasing the load. - Fine dust filter to protect the vacuum pump - Detailed and easy to understand documentation. One year warranty against material and manufacturing defects One-shift operation (without wearing parts). Initial test UVV 18, VBG 9a with CE declaration of conformity - according to EN 13155 - Packing for truck transport.

- A + B Werkzeuge Maschinen Handels GmbH

- Rottweg 17

- 48683 Ahaus

- Deutschland

-

(0049)-2561-9384-71

(0049)-2561-9384-36 -

info@ab-maschinen.de

www.ab-maschinen.de

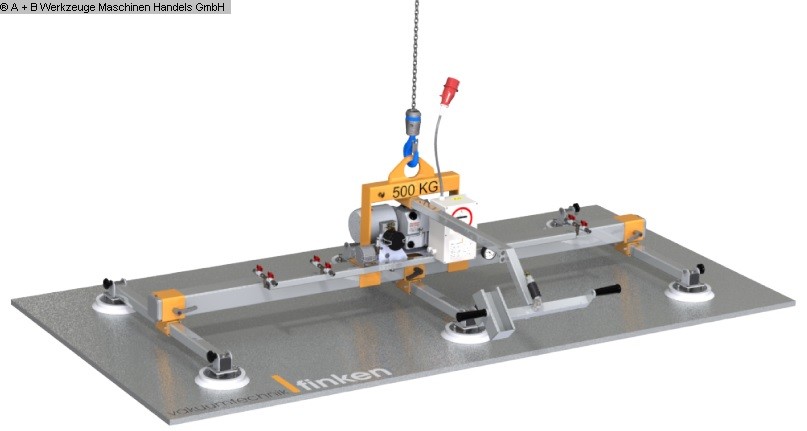

#1008-8531720 · Vacuum-Lifter

FINKEN - VH 6-500 - - -

Technical details

Furnishing : - for the horizontal transport of smooth, dry and airtight panels - Robust supporting structure made of steel - Painted in RAL 2000 with low weight - Galvanized longitudinal beam with a length of 2,400 mm - 3x galvanized crossbeams with a length of 1,000 mm - 6x springy, articulated and adjustable suction cup holders - 6x suction cups Ø 215 mm - Low-maintenance, very high-quality, dry-running rotary vane vacuum pump - with a suction capacity of 8 m³/h and a final vacuum of 85% (150 mbar) - 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) - Operating handle can be extended to 1,000 mm from the center of the traverse - Sturdy metal case for your crane control - Operation "suction / release" by hand slide valve - Control and safety device for vacuum lifters * Robust control box. * Contactor circuit for the vacuum pump * Safety warning device with audible alarm * Vacuum gauge with danger zone indicator * Large vacuum storage tank with safety check valve * Double actuation when releasing the load - Fine dust filter to protect the vacuum pump - Documentation * Special accessories included: - 6x ball valves to switch off individual suction cups * so that smaller formats can also be lifted * without having to move suction cups or traverses - Spiral connection cable small helix * with an extension length of 3,500 mm, version as * Extension cable with CEE plug and coupling * is routed to the lifting device next to the load chain

Datasheet

Request / Contact