Boring mills - Machining Centers - Drilling machines

Machinelist: Boring mills / Machining Centers / Drilling machines

Deephole Boring Machine

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-02482 · Deephole Boring Machine

WOHLENBERG - B 10 S - - 1971 -

Technical details

Drill pipes, guide block, drill head, rolling steady rest, support bearing drill heads, jaws 21- 240 mm, Holder, tools, shelves, cupboards

- Harry Vraets Machinery B.V.

- Gezellenstraat 2

- 3861RD Nijkerk

- Niederlande

-

+31 (0)332452145

-

info@vraetsmachinery.com

www.vraetsmachinery.com

#2039-12405EH · Deephole Boring Machine

WOHLENBERG - B 10 S - - 1971 -

Technical details

Drill pipes, guide block, drill head, rolling steady rest, support bearing drill heads, jaws 21- 240 mm, Holder, tools, shelves, cupboards

Floor Type Boring and Milling M/C - Hor.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

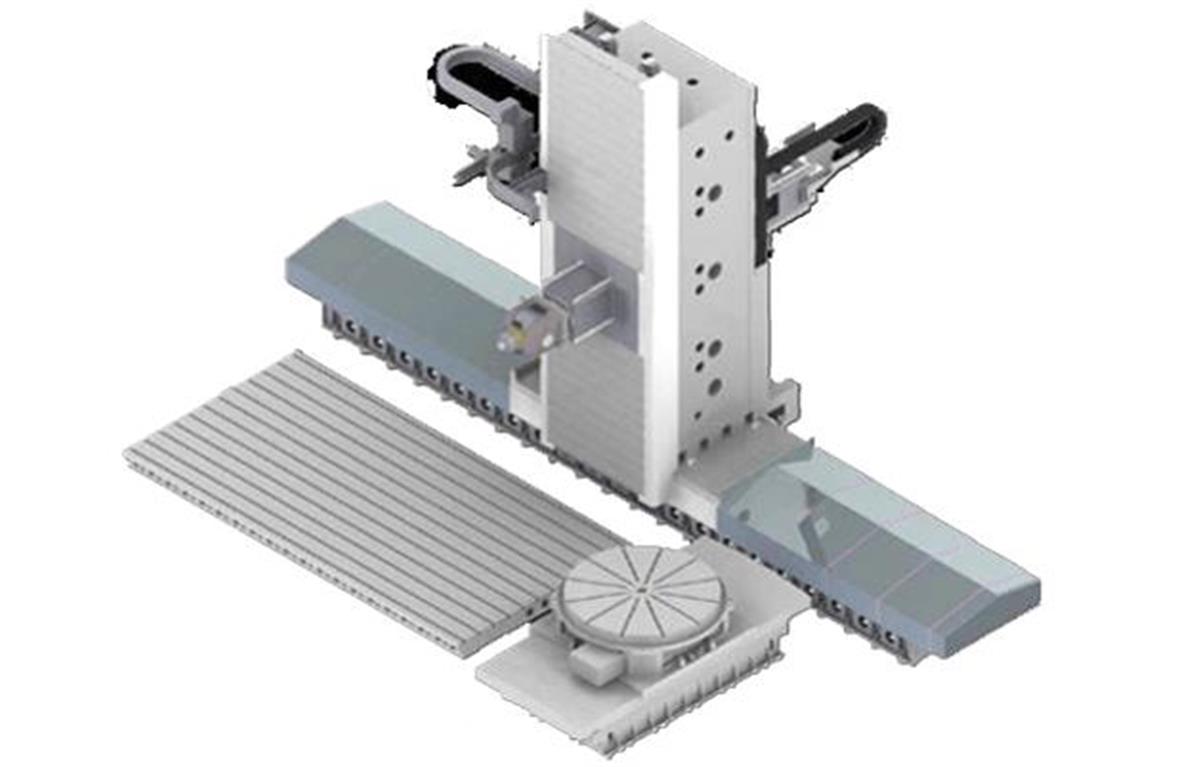

#4019-97200 · Floor Type Boring and Milling M/C - Hor.

KRAFT - FBM-160 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Factory-new CNC controlled panel drilling machine with CNC control from Siemens / Fanuc / Heidenhain. All essential components from well-known manufacturers such as Siemens, SKF, FAG, Heidenhain, Igus and many more. Newly developed FB series Convenient for a variety of manufacturing applications Modular arrangement With a variety of options for even greater productivity and application diversity Machine layout: · Extra-wide flat guides with heavy-duty roller guides for heavy-duty machining · High table loadability · High-precision table Spindle: · Highly accurate and highly rigid spindle pair from SKF · Constant temperature oil cooling and thermal spindle compensation system · Optimized span to ensure a rigid spindles system · Removable spindle sleeve Stand: · High-quality sand-based cast iron from our own foundry · Double thermal aging for stable precision · The FEA optimization design ensures high stiffness · Wide guide rails for heavy milling and drilling operations · Large cross-section column Machine bed: · Heavy machine bed from our own foundry · Double thermal aging for stable precision · The FEA optimization design ensures high stiffness · Rolling body from INA · Guide rails are coated with Teflon Table: · Precision ball screw spindle (Germany Rexroth) drives the X axis · B-axis uses a high-precision double pinion to eliminate transmission play and ensure transmission accuracy · Glass measuring rods with high accuracy - (HEIDENHAIN) · Angle encoder (HEIDENHAIN) · B-axis with powerful hydraulic clamping · B axis of rotation includes: servomotor, worm gear, double pinion and transmission structure. Drive system: · High-precision C3 ball screw drive from Rexroth, the double nut is prestressed and ensures high accuracy · Imported synchronous belt drive - ensures robust drive power · Couplings of KTR (FRG) for maximum reliability Further technical data and accessories, according to the appendix. We have this machine in stock and available at short notice. Ask us about it! The travel costs for the visit will be charged to you at the time of purchase. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing. Ask us about it. Of course, you also receive from us free delivery, assembly / commissioning and ready-to-hand transfer as well as control training. Fig. Shows FB-130.

Machining Center - Horizontal

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91680 · Machining Center - Horizontal

KRAFT - HA-400II - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Brand new horizontal machining center with: CONTAINS: 1. Control system Fanuc Oi-MF (10.4" Screen) 2. Working table size: 400 x 400 mm 3. Max. workpiece dimension: DIA. 630 x H 800 mm 4. Max. table load capacity: 400 kgs x 2 pallets 5. Spindle center to table surface: 80 ~ 660 mm 6. Table center to spindle nose: 70 ~ 650 mm 7. X/Y/Z Stroke 610/580/580 mm 8. X/Y/Z Stroke rapid traverse: 60/60/60 m/min 9. Spindle motor 22/25 KW (built-in type) 10. Spindle speed 12000 RPM with spindle cooler 11. Spindle nose NT#40 (BT40) 12. ATC capacity 60 tools 13. Coolant unit (rear side of machine) 14. Coolant thru. spindle W/H high pressure pump (20bar) and filter system (A type) 15. Full splash cover 16. Rotart type APC unit x 2 working pallets (400x400mm) 17. 4th axis (B-axis) function index 1 degree positioning 18. Electric cabinet with heat exchanger 19. Transformer (power source 380V) 20. Rigid Tapping 21. Manual pulse generator 22. Chip conveyor H=1100 mm with trolley (integrated type)on the rear side 23. Auger type chip screws inside of machine bed 24. New design machine cover & color scheme 25. Fanuc warranty OPTIONS: 1. CE Mark 2. Balance of 4th axis (B-axis) index 0.001 positioning 3. Coolant gun with on/off switch 4. Oil skimmer (disc type) 5. Manual guide I function

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91685 · Machining Center - Horizontal

KRAFT - HA-500II - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Brand new horizontal machining center with: CONTAINS: 1. Control system Fanuc Oi-MF (10.4" Screen) 2. Working table size: 400 x 400 mm 3. Max. workpiece dimension: DIA. 630 x H 800 mm 4. Max. table load capacity: 400 kgs x 2 pallets 5. Spindle center to table surface: 80 ~ 660 mm 6. Table center to spindle nose: 70 ~ 650 mm 7. X/Y/Z Stroke 610/580/580 mm 8. X/Y/Z Stroke rapid traverse: 60/60/60 m/min 9. Spindle motor 22/25 KW (built-in type) 10. Spindle speed 12000 RPM with spindle cooler 11. Spindle nose NT#40 (BT40) 12. ATC capacity 60 tools 13. Coolant unit (rear side of machine) 14. Coolant thru. spindle W/H high pressure pump (20bar) and filter system (A type) 15. Full splash cover 16. Rotart type APC unit x 2 working pallets (400x400mm) 17. 4th axis (B-axis) function index 1 degree positioning 18. Electric cabinet with heat exchanger 19. Transformer (power source 380V) 20. Rigid Tapping 21. Manual pulse generator 22. Chip conveyor H=1100 mm with trolley (integrated type)on the rear side 23. Auger type chip screws inside of machine bed 24. New design machine cover & color scheme 25. Fanuc warranty OPTIONS: 1. CE Mark 2. Balance of 4th axis (B-axis) index 0.001 positioning 3. Coolant gun with on/off switch 4. Oil skimmer (disc type) 5. Manual guide I function

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91692 · Machining Center - Horizontal

KRAFT - HB-630 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Brand new horizontal machining center with: CONTAINS: 1. Control system Fanuc Oi-MF (10.4" Screen) 2. Working table size: 400 x 400 mm 3. Max. workpiece dimension: DIA. 630 x H 800 mm 4. Max. table load capacity: 400 kgs x 2 pallets 5. Spindle center to table surface: 80 ~ 660 mm 6. Table center to spindle nose: 70 ~ 650 mm 7. X/Y/Z Stroke 610/580/580 mm 8. X/Y/Z Stroke rapid traverse: 60/60/60 m/min 9. Spindle motor 22/25 KW (built-in type) 10. Spindle speed 12000 RPM with spindle cooler 11. Spindle nose NT#40 (BT40) 12. ATC capacity 60 tools 13. Coolant unit (rear side of machine) 14. Coolant thru. spindle W/H high pressure pump (20bar) and filter system (A type) 15. Full splash cover 16. Rotart type APC unit x 2 working pallets (400x400mm) 17. 4th axis (B-axis) function index 1 degree positioning 18. Electric cabinet with heat exchanger 19. Transformer (power source 380V) 20. Rigid Tapping 21. Manual pulse generator 22. Chip conveyor H=1100 mm with trolley (integrated type)on the rear side 23. Auger type chip screws inside of machine bed 24. New design machine cover & color scheme 25. Fanuc warranty OPTIONS: 1. CE Mark 2. Balance of 4th axis (B-axis) index 0.001 positioning 3. Coolant gun with on/off switch 4. Oil skimmer (disc type) 5. Manual guide I function

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91694 · Machining Center - Horizontal

KRAFT - HB-800 - - Fabrikneu - Siemens/Fanuc/Heidenhain

Technical details

Brand new horizontal machining center with: CONTAINS: 1. Control system Fanuc Oi-MF (10.4" Screen) 2. Working table size: 400 x 400 mm 3. Max. workpiece dimension: DIA. 630 x H 800 mm 4. Max. table load capacity: 400 kgs x 2 pallets 5. Spindle center to table surface: 80 ~ 660 mm 6. Table center to spindle nose: 70 ~ 650 mm 7. X/Y/Z Stroke 610/580/580 mm 8. X/Y/Z Stroke rapid traverse: 60/60/60 m/min 9. Spindle motor 22/25 KW (built-in type) 10. Spindle speed 12000 RPM with spindle cooler 11. Spindle nose NT#40 (BT40) 12. ATC capacity 60 tools 13. Coolant unit (rear side of machine) 14. Coolant thru. spindle W/H high pressure pump (20bar) and filter system (A type) 15. Full splash cover 16. Rotart type APC unit x 2 working pallets (400x400mm) 17. 4th axis (B-axis) function index 1 degree positioning 18. Electric cabinet with heat exchanger 19. Transformer (power source 380V) 20. Rigid Tapping 21. Manual pulse generator 22. Chip conveyor H=1100 mm with trolley (integrated type)on the rear side 23. Auger type chip screws inside of machine bed 24. New design machine cover & color scheme 25. Fanuc warranty OPTIONS: 1. CE Mark 2. Balance of 4th axis (B-axis) index 0.001 positioning 3. Coolant gun with on/off switch 4. Oil skimmer (disc type) 5. Manual guide I function

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100504 · Machining Center - Horizontal

KRAFT - LH-630B - - 2020 - SIEMENS 840D SL - SHOPMILL

Technical details

Brand new horizontal machining center with: CONTAINS: 1. Control system Fanuc Oi-MF (10.4" Screen) 2. Working table size: 400 x 400 mm 3. Max. workpiece dimension: DIA. 550 x H 800 mm 4. Max. table load capacity: 400 kgs each pallet 5. Spindle center to table surface: 80 ~ 590 mm 6. Table center to spindle nose: 70 ~ 580 mm 7. X/Y/Z Stroke 510/510/510 mm 8. X/Y/Z Stroke rapid traverse: 60/60/60 m/min 9. Spindle motor 18,5/25/37 KW 10. Spindle speed 15000 RPM (built-in type) 11. Spindle cooler 12. Spindle nose BBT40 13. ATC capacity 40 tools 14. Coolant unit (rear side of machine) 15. Coolant thru. spindle W/H high pressure pump (20bar) and filter system (A type) 16. Full splash cover 17. Rotart type APC unit x 2 working pallets (400x400mm) 18. 4th axis (B-axis) function index 0.001 degree positioning 19. Electric cabinet with heat exchanger 20. Transformer (power source 380V) 21. Rigid Tapping 22. Manual pulse generator 23. Chip conveyor H=1100 mm with trolley (integrated type)rear side discharge 24. New design machine cover & color scheme 25. Fanuc warranty (Western Europe) OPTIONS: 1. CE Mark 2. Upgraded ATC capacity 60 tools 3. Coolant gun with on/off switch 4. Oil skimmer (disc type) 5. Manual guide I function

Machining Center - Universal

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100287t · Machining Center - Universal

KRAFT - GT 630 5x - - 2018 - Heidenhain iTNC-530

Technical details

Factory new, immediately available CNC 5-axis universal machining center with CNC control HEIDENHAIN TNC 530 GT-630 Five axis Vertical Machining Center Type Milling Machine type Vertical Machining Center 5-Axis Travel x-as 760 mm Travel y-as 820 mm Motor 40 Kw Spindle speed 15000 rpm Tool capacity 32 Machine structure Casting components on this machine are made of high quality cast iron. The Y-axis is driven by a single ball screw at the center of gravity to ensure the parallelism of slide moving The gravity center of Y-axis moving components falls within the supporting range of sliding block, it decreases the decline of spindle and improves dynamic stability. Less overhung spindle provides excellent rigidity in heavy duty machining. Spindle unit and table The spindle is equipped with an oil lubrication bearing and oil cooling cartridge, it constrains the thermal generation and reduces the thermal expansion in the spindle. The spindle is suitable for long hour machining and available with thermal compensation mechanism (optional) The rotating axis of the table is driven by DD motor to provide higher speed an higher precision. The table is equipped with a roller gear mechanism, this provides lower friction, easy activate for high speed rotation and high precision back lash. For technical details please download the PDF brochure. Our Taiwanese supplier is the largest manufacturer in Taiwan and also builds lathes and machining centers for well-known Japanese manufacturers. The delivery warehouse is in the Netherlands. We carry out the personnel service for these machines. Spare parts are available in the Netherlands and can be delivered at short notice. However, we are the first point of contact in all matters, whether it is delivery, assembly / commissioning, training or after-sales service. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing. Ask us about it. Of course, you also receive from us free delivery, assembly / commissioning and ready for handover as well as control training. Also possible financing.

Machining Center - Vertical

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91150 · Machining Center - Vertical

KRAFT - VF 108 - - Fabrikneu - FANUC/Siemens/Heidenhain

Technical details

Brand-new CNC vertical machining center with CNC control FANUC or HEIDENHAIN Warranty: 12 months More information can be found in the Appendix.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-240123 · Machining Center - Vertical

KRAFT - VF 108 - - Fabrikneu - Siemens 828D

Technical details

Brand-new CNC vertical machining center with CNC control FANUC or HEIDENHAIN Warranty: 12 months More information can be found in the Appendix.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91160 · Machining Center - Vertical

KRAFT - VL 700A | VL 1100A | VL 1100D - - Fabrikneu - Siemens/Fanuc

Technical details

Brand-new CNC vertical machining center with CNC control Siemens 828D with Shopmill. Incl. the following standard accessories: CNC control Siemens 828D with SHOPMILL including 2-year warranty 1 piece coolant system 1 piece automatic 20-fold tool changer (Model VL-700), Type „ARM TYPE ATC“ 1 piece automatic 24-fold tool changer (Model VL-900, VL-1100, VB-1000, VB-1200, VB-1600), Type „ARM TYPE ATC“ 1 piece Halogen Machine Lamp 1 piece alarm / indicator lamp rigid tapping 1 set of tools 1 piece chip conveyor (chain) 1 piece tool set (water gun, air gun) 1 set foundation blocks and fixture screws heat exchanger for electric cabinet automatic lubrication system full enclosure guard automatic power off Spindle speed of 8000 U / min (Model VL-700, VL-900, VL-1100, VB-1000) Spindle speed of 6000 U / min (Model VB-1200, VB-1600) linear guide (VL-Serie) from THK or Rexroth 1 set of operating manual with spare parts list in German language 400V, 50cps, 3 phs CE version incl. CE Declaration of Conformity belt drive with 10.000 U/min door interlock 8,4” Screen spindle chiller coolant through spindle center tool setter (Blum) Warranty: 12 months More information can be found in the Appendix.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91165 · Machining Center - Vertical

KRAFT - VL 1400 | VL 1600 - - Fabrikneu - Siemens/Fanuc

Technical details

Brand-new CNC vertical machining center with CNC control Siemens 828D with Shopmill. Incl. the following standard accessories: CNC control Siemens 828D with SHOPMILL including 2-year warranty 1 piece coolant system 1 piece automatic 20-fold tool changer (Model VL-700), Type „ARM TYPE ATC“ 1 piece automatic 24-fold tool changer (Model VL-900, VL-1100, VB-1000, VB-1200, VB-1600), Type „ARM TYPE ATC“ 1 piece Halogen Machine Lamp 1 piece alarm / indicator lamp rigid tapping 1 set of tools 1 piece chip conveyor (chain) 1 piece tool set (water gun, air gun) 1 set foundation blocks and fixture screws heat exchanger for electric cabinet automatic lubrication system full enclosure guard automatic power off Spindle speed of 8000 U / min (Model VL-700, VL-900, VL-1100, VB-1000) Spindle speed of 6000 U / min (Model VB-1200, VB-1600) linear guide (VL-Serie) from THK or Rexroth 1 set of operating manual with spare parts list in German language 400V, 50cps, 3 phs CE version incl. CE Declaration of Conformity belt drive with 10.000 U/min door interlock 8,4” Screen spindle chiller coolant through spindle center tool setter (Blum) Warranty: 12 months More information can be found in the Appendix.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-060123 · Machining Center - Vertical

KRAFT - VL 1100A - - Fabrikneu - FANUC Oi MF plus

Technical details

Brand-new CNC vertical machining center with CNC control Siemens 828D with Shopmill. Incl. the following standard accessories: CNC control Siemens 828D with SHOPMILL including 2-year warranty 1 piece coolant system 1 piece automatic 20-fold tool changer (Model VL-700), Type „ARM TYPE ATC“ 1 piece automatic 24-fold tool changer (Model VL-900, VL-1100, VB-1000, VB-1200, VB-1600), Type „ARM TYPE ATC“ 1 piece Halogen Machine Lamp 1 piece alarm / indicator lamp rigid tapping 1 set of tools 1 piece chip conveyor (chain) 1 piece tool set (water gun, air gun) 1 set foundation blocks and fixture screws heat exchanger for electric cabinet automatic lubrication system full enclosure guard automatic power off Spindle speed of 8000 U / min (Model VL-700, VL-900, VL-1100, VB-1000) Spindle speed of 6000 U / min (Model VB-1200, VB-1600) linear guide (VL-Serie) from THK or Rexroth 1 set of operating manual with spare parts list in German language 400V, 50cps, 3 phs CE version incl. CE Declaration of Conformity belt drive with 10.000 U/min door interlock 8,4” Screen spindle chiller coolant through spindle center tool setter (Blum) Warranty: 12 months More information can be found in the Appendix.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100285 · Machining Center - Vertical

KRAFT - K-mill 850QII - - 2020 - MANUAL GUIDE i FUNCTION + 10.4

Technical details

Factory-new, immediately available, vertical CNC machining center with CNC control MANUAL GUIDE i FUNCTION + 10.4 "LCD MONITOR. Our Taiwanese supplier is the largest manufacturer in Taiwan and also builds lathes and machining centers for well-known Japanese manufacturers. The delivery warehouse is in the Netherlands. We carry out the personnel service for these machines. Spare parts are available in the Netherlands and can be delivered at short notice. However, we are the first point of contact in all matters, whether it is delivery, assembly / commissioning, training or after-sales service. Further data can be found in the annexes. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing: Ask us about it! Installation and service possible by qualified personnel.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100335 · Machining Center - Vertical

KRAFT - K-mill 1050 mit HH TNC 620 - - 2020 - HEIDENHAIN TNC620 (MC1620)

Technical details

Factory-new, immediately available, vertical CNC machining center with: 1. CONTROL SYSTEM HEIDENHAIN TNC620 (MC1620) 2. WORKING TABLE SIZE 1100 × 600 MM 3. X/Y/Z AXIS STROKE 1050/600/530 MM 4. X/Y/Z AXIS RAPID TRAVERSE 48/48/48 M/MIN 5. SPINDLE MOTOR 7.5 (QAN 200L) 6. SPINDLE SPEED 8000 RPM (BELT-DRIVEN TYPE) 7. SPINDLE NOSE NT#40 (BT40) 8. ATC CAPACITY 24 TOOLS 9. STANDARD SPLASH GUARD 10. MANUAL PULSE GENERATOR 11. COOLANT UNIT 12. RIGID TAPPING 13. WITHOUT TRANSFORMER (POWER SOURCE 380V) 14. AUGER TYPE CHIPS SCREWS INSIDE OF MACHINE BED 15. MACHINE COLOR TONGTAI GREY/BLUE 16. TRICOLOR LIGHT 17. HEIDENHAIN WARRANTY OPTIONS: 1. CE MARK 2. SPINDLE SPEED 10.000 RPM, 10KW QAN 200L (BELT DRIVEN TYPE) 3. SPINDLE COOLER 4. COOLANT THROUGH SPINDLE WITH HIGH PRESSURE PUMP (20 BAR) FILTERSYSTEM TYPE A 5. FULL SPLASH COVER 6. ATC TOOL CAPACITY 30 TOOLS 7. A/C FOR ELECTRICAL CABINET 8. MANUAL GUIDE i FUNCTION + 10.4" LCD MONITOR 9. CHIP CONVEYOR H=1100 MM WITH TROLLEY (CHAIN TYPE) Our Taiwanese supplier is the largest manufacturer in Taiwan and also builds lathes and machining centers for well-known Japanese manufacturers. The delivery warehouse is in the Netherlands. We carry out the personnel service for these machines. Spare parts are available in the Netherlands and can be delivered at short notice. However, we are the first point of contact in all matters, whether it is delivery, assembly / commissioning, training or after-sales service. Further data can be found in the annexes. Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing: Ask us about it! Installation and service possible by qualified personnel.

Radial Drilling Machine

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91660 · Radial Drilling Machine

KRAFT - RB 50 | RB 63 | RB 80 - - Fabrikneu -

Technical details

payment: 100 % before loading warranty:12 months

23.900 €

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91665 · Radial Drilling Machine

KRAFT - RB 100 | RB 120 - - Fabrikneu -

Technical details

payment: 100 % before loading warranty:12 months

Table Type Boring and Milling Machine

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-94300 · Table Type Boring and Milling Machine

KRAFT - HBM-110 | HBM-110L | HBM-110XL - - Fabrikneu - oder CNC

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-91280 · Table Type Boring and Milling Machine

KRAFT - WHM-110 - - Fabrikneu -

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-94305 · Table Type Boring and Milling Machine

KRAFT - HBM-130 | HBM-130L | HBM-130XL - - Fabrikneu - oder CNC

Technical details

Technical Offer of HBM-130 ? Powerful servo spindle motor and four spindle speed rang, stepless in each range. much lower maintenance and 80% failure rate reduced ? High rigidity spindle could insure the strong machining ? Worktable 4x90° position by the collimator ? X,Y, Z, B axes DRO are available ? Spindle could choose ISO50, with automatic clamping 1. Introduce The horizontal boring and milling machine series HBM-130 of our company is suitable for such operation as drilling, counter-boring, boring, reaming, spot-facing, tapping and milling etc. Also the horizontal boring and milling machine type is equipped with fixed facing head on which radial facing slide can be radically feed consequently to enable the machine to undertake boring of large-diameter hole, external cutting ,end face turning and recessing, etc. The machine is composed of bed, front column, headstock, cross and longitudinal saddle, worktable, back column and balance weight pulley etc. The vertical movement of headstock goes along the column's guideway, the worktable can move transversely and longitudinally on the bed, and the worktable can be rotated. The characteristics of HBM-130 2.1 The big servo spindle 22KW motor supply continuously speed change and high torque output of headstock. Four speed range can be changed by the selector on the control panel. The infinit speed change in each range can be effected continuously and smoothly. It’s very simple and convenient for machine operation. Compare with old headstock structure, 24 steps speed changing by hydraulic, the failure rate will be reduced 80%. 2.2 The vertical coordinate ( headstock lifting direction ) and cross coordinate ( worktable transverse movement ) and longitudinal coordinate ( worktable longitudinal movement--option ) are provided with new type digital read out unit with memory function, which makes the machine with complete function and high accuracy. 2.3 Main parts of the machine such as bed, front column and guideways of longitudinal saddle are all hardened and ground, which bring high stiffness of the guideways and extend the using life of the machine. 2.4 The horizontal guideway surface of the machine is provided with all pull-board type dust-proof. 2.5 Electric-hydraulic interlocking device will be fixed between the moving units and when a moving unit is working, the other moving units will be clamped automatically (except spindle, radial facing slide). 2.6 In the rapid traverse gearbox, safety clutches are installed to prevent the machine from overload. 3. Transmission systems of the machine 3.1 Headstock transmission The rotation movement of boring spindle are driven by CTB servo spindle motor directly. Insteady of old design, 24 steps spindle speed, the spindle servo motor supply two range speed. Low spindle speed with big torque output and high spindle speed with stable and continuously cutting forece. 3.2 Feed motion The feed motion of all moving units of this machine is feeding per spindle revolution (e.g. traverse rate of spindle, headstock, table per spindle revolution).The power of various moving units comes from shaft driven by main driven motor. It can be transmitted through gears of speed-change device to shaft (the feed safety mechanism). After that the motion will be transmitted further through the forward and reverse mechanism, to the feed shaft, then to the lead-screw or gear racks of various moving units, enable the headstock, cross & longitudinal saddles to obtain each 18 steps feed rates at low and high gear respectively. The feed motion of the radial slide on the facing head comes from headstock, enable it to obtain various feed rates. 3.3 Rapid transmission system The rapid moving of the headstock,cross & longitudinal saddles of the machine and the rapid rotation of the rotary worktable are driven by AC motor mounted at the right side of the bed. Power from the motor is transmitted from shafts coupling and friction clutch to each moving units respectively, enable the spindle, headstock and cross & longitudinal saddles to obtain the rapid moving speed 2500mm/min, the rapid rotation of the worktable is 1r/min. 4. Hydraulic system of the machine The hydraulic system is located inside of longitudinal saddle of the machine, which is used for the transverse of headstock, longitudinal & cross movement, rotation of worktable, feed speed change and internal lubrication of headstock

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100416 · Table Type Boring and Milling Machine

KRAFT - HBM-110 - - 2020 - konventionell

Technical details

Machining centres are multi-functional tools in the maching of solid materials usually metals. They are distinguished from other forms of cutting by the fact that the machining centre itself moves as opposed to the work piece. Machining centres also known as milling machines come in a variety of sizes from small models for home workspaces to large industrial models for factories. Find your next used machining centre at LagerMaschinen your source for quality used equipment.

Enhance your business' efficiency with a machining centreThe term 'machining centre' can be further subdivided into specific types of centres namely horizontal and vertical based on the orientation of the spindle. A vertical machining centre is usually best suited projects where intricacy and precision are required while horizontal machining centres offer operators a higher rate of production and output. Whether you're shopping as a hobbyist or a business owner you can find the right used machining centre for you from wide selection available at LagerMaschinen.

Experiences the advantages of shopping at LagerMaschinenBuying used machinery online is a practical solution to time and budgetary concerns. When you browse LagerMaschinen's easy-to-use site you'll quickly see the many advantages to shopping for used equipment online. You can search from the comfort of your home or office sort your results by price location or model and best of all the wide selection of products available guarantees you'll find the perfect machining centre for your home or business. Save time and money at LagerMaschinen.

The term 'boring machines' includes a wide range of equipment used to create holes in a variety of different materials. Boring machines can come in large range of sizes as well. Small boring machines are perfect for wood workers or home hobbyists, while larger equipment is suited to industrial settings. Lathes, machining centres and boring mills all fall under the umbrella of boring machines. For the best selection of used boring machines, check out the best online machinery marketplace, LagerMaschinen.

Which type of used machines is right for you?Boring mills and machining centres are amongst the most popular boring machines. They can be subdivided into two main categories based on the orientation of the boring bar. Boring mills and machining centres are known for their precision cutting techniques and are perennial industry favourites. Purchasing boring mills or machining centres doesn't have to cost your business a fortune. By investing in used machines online, you can get the quality you demand without breaking your budget.

LagerMaschinen: the easiest way to find used machines onlineIn today's economy, time and money are two of the most valuable assets we have. Making the most of both is advantageous for both businesses and individuals. If you're in the market for industrial machinery or even small-scale equipment for your home workshop or factory, why not consider investing in used machines. Shopping for used machines online at LagerMaschinen takes the hassle out of the browsing process. Find boring machines presses and drills quickly and easily using LagerMaschinen.

TOP Manufacturer:

ALZMETALL - ERLO - HUVEMA - UNION - TOS - KRAFT - MORI SEIKI - MAZAK - DECKEL MAHO - BERNARDO -