Machine data

Document

Keine weiteren Dokumente vorhandenTechnical details

| charge load | / |

| / | |

| Dimensions (L/W/H) | 1090/1090/940 mm |

| weight | 350 kg |

| 0 | 250 l |

Videos

Keine Video-Dateien vorhandenAdditional information

– For different processes with different dimension stone types in the same

machine

– Usually for large-sized and sensitive parts

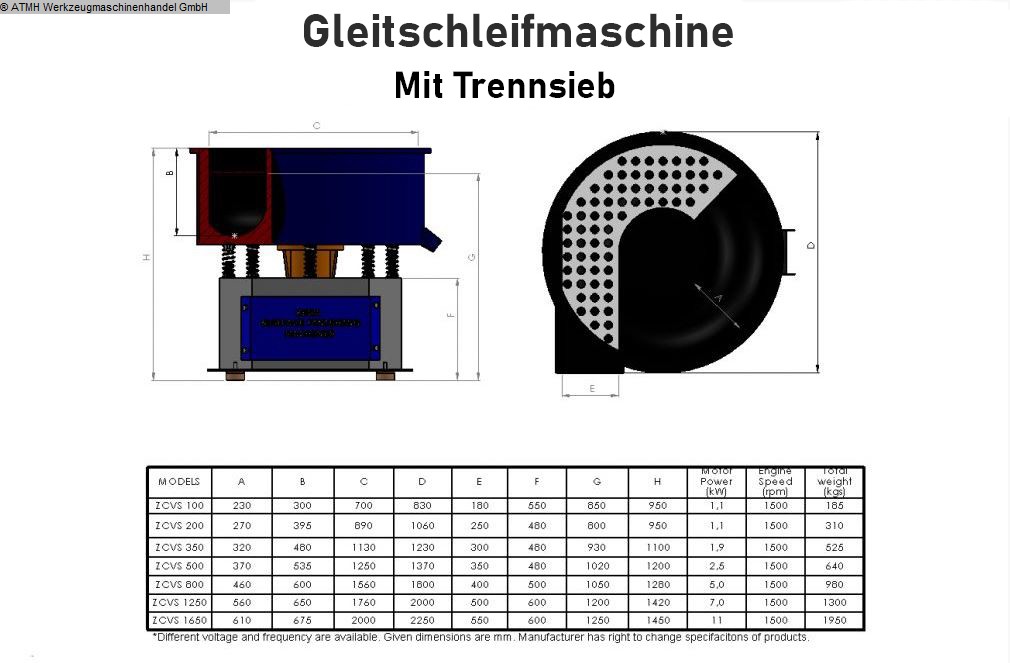

– Various volumes in the range of 20lt – 1250lt

– Without seperating system

– Deburring and polishing for all kinds of metal and non-metal materials

– Suitable for automation system

– Optional accessories

ZCV Series machines are used for deburring, polishing, roughness removal, oil

and rust removal, descaling, colour changing, delustering, aging etc processes

for metal or non-metal materials.

The machines in this series are generally suitable for big size and sensitive

parts, and the processed parts are collected manually by the staff at the end

of the process.

The bowl design is one of the important factors to achieve the desired surface

quality in the part by keeping the process time in minimum.

The O-shaped design of the bowl is designed by considering vibration

optimization and optimal kneading motion. The bowl is made of special steel and

has a tension-free and vibration-resistant welding structure.

The chassis height and springs are ergonomically designed so that staff can

work with high efficiency.

Its resistance against vibrations has been increased; with rigid and reinforced

support construction; adjustable insulators flexibly mounted to absorb

vibrations are some of the design features of the machine chassis.

Long-lasting special motor series is used which have CE and Ex standards, high

performance, cast-bodied, hollow roller bearings and it does not require

lubrication.

Inside of the bowl is covered with 90 Shore polyurethane material which is

resistant to abrasion. In this way, a long service life is achieved without

requiring repair and maintenance.

Makinalarimizda açip kapatmasi kolay tas bosaltma bölümü bulunmaktadir.

Our machines have a chip unloading section that is easy to open and close.

Electrical panels with CE Certificate, designed in accordance with EU

standards, are used. There are main switch and emergency stop switch. The

working time controller and time clock are included in the standard equipment.

Three-phase electrical connection is used.

Optionally, dosing pump control, speed control unit, valve control unit etc.

can be added to the electrical panel. It can work integrated with automation

systems with PLC software

There are clean water inlet and waste water discharge valves. If preferred,

standard water valves can be replaced as solenoid valves. In this case, valve

on-off control can be done from the electrical panel.

The dosing pump mounted on the machine is installed as standard. The dosing

pump automatically sprays the chemicals used in the process in desired periods.

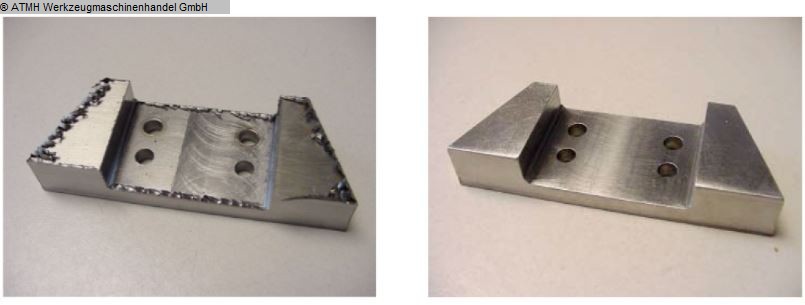

On this page you will find a an offer on a used Slip Grinding Machine of type ZCVS 250 of the company ZEGA with year of construction and with stock no.: 2065-H1088. The machine is manufactured by the company ATMH Werkzeugmaschinenhandel GmbH from 58256 Ennepetal offered. The delivery time / delivery status for this machine is: Nach Absprache For more information, please refer to the details listed.

Документи та відео

Keine weiteren Dokumente vorhanden

Keine Video-Dateien vorhanden

Machine

Slip Grinding Machine