Machines available immediately

Machinelist: Machines available immediately

Frame press

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6803 · Frame press

SCHAFBERGER + SPROEDHUBER - RP 1200 - - gebraucht -

Technical details

S+S hydraulic frame press RP 1200 ------------------------------------- Working width 3,550 mm Working height 2,250 mm ------------------------------------- with medium pressure beam ------------------------------------- still in use ------------------------------------- Technical information according to the manufacturer - without guarantee!)

2.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6821 · Frame press

CASOLIN - Euro - - 2010 -

Technical details

Casolin Euro ------------------------- HYDRAULIC FRAME PRESS FOR WINDOWS AND DOORS CASOLIN MOD. "EURO" Frame press in an extremely stable steel construction. The machine also allows the pressing of already milled wing and frame parts. Working dimensions: 6000mm x 3000mm Installation dimensions: Total length: approx. 7,175 mm Installation height approx.: 3,790 mm + 340 mm (cylinders look when pressed maximum pressing height above) = 4,130 mm Loading dimensions: Length: approx. 7,175 mm Height: approx. 3,790 mm Weight: approx. 3,700 kg (technical data according to the manufacturer - no guarantee!)

20.000 €

Datasheet

Request / Contact

Glazing and control press

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6819 · Glazing and control press

Ruchser - RU-VGPA3 - - gebraucht -

Technical details

Glazing press with equipment ----------------- Working dimensions: Length: 3,000mm Height: 2,500mm Total length: 3,700 mm System height: 1,900 mm Press beam height: 2,200 mm ----------------- Manual width adjustment Height adjustment pneumatic lifting device 500mm ----------------- (Technical information according to the manufacturer - no guarantee!)

2.500 €

Datasheet

Request / Contact

Glazing bead sww

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6873 · Glazing bead sww

STRIFFLER - 2733 - - 1991 - manuel

Technical details

STRIFFLER glass bead saw 2733 Miter cut 45 degrees with manual feed, pneumatic slot stop for glazing beads with slots and tenons, manual length stop with scale. (technical data according to the manufacturer - no guarantee!)

1.000 €

Datasheet

Request / Contact

Olive boring machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6783 · Olive boring machine

GANNER - Olivenbohrmaschine - - gebraucht -

Technical details

Ganner olive drilling machine Still in use and to visit!

800 €

Datasheet

Request / Contact

Outside profiling machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6827 · Outside profiling machine

WEINIG - Univar 6 P - - gebraucht -

Technical details

Weinig Univar 6 P In order to sell ---------------------- Operating voltage: 380 volts, 50 periods. For milling around windows, doors and similar with uneven edges Profiles. Arrangement of the aggregates: 1. Synchronous spindle on the right, pneumatically clocked. 2. Profiling spindle on the right 3. Fitting spindle Profiling spindle suitable for holding several tools one on top of the other. Spindle movement pneumatic. The 1 spindle works in synchronization for tear-free milling. Respectively This spindle plunges the last 100 mm of a frame end with the Insert the appropriate tool into the wood to prevent tearing at the frame corners avoid. Machine stands, tables, stops: Machine body made of heavy, torsion-free and vibration-damping elements. Stops on the right in the profiling area made of Pertinax. Before Profiling spindle a split stop with sliding bar for short parts. Additional opening rail for large format frames. Feed system: Continuous, chainless feed equipped with rubber rollers. Blow-off device for feed rollers and table. Spindles, hood: Spindles with high concentricity and dynamically balanced. Extraction hoods designed for the cheapest chip flow. Easiest tool change Quick-opening hood lid. Machine operation, setting aids: Operating the machine from the front. Setting the stops for Tool diameter using mechanical number display. Machine electrics, motors, controls: Electrical design according to DIN VDE 0113 - Electrical equipment from Industrial machines EN 60204 IEC 204-1. Further electrical regulations are not taken into account. Engines dynamically balanced. Control of tool positions via selector switch on the control panel. Tools: Machine equipped with operating tools, but without Editing tools. SPINDLE 1 Synchronous spindle Number of tools: 1 Spindle speed: 6000 rpm Spindle diameter: 50mm Tool clamping length: 120 mm Tool diameter max. (milling): 232 mm Tool zero flight circle: 112-140 mm Basic position under table: 10 mm Motor strength: 4 KW (5.5 KW) SPINDLE 2 Number of tools: 4 Spindle stroke vertical: 3 x 80 mm = 4 tools Can be switched to 2 x 95 mm = 3 tools Spindle speed: 6000 rpm Spindle diameter: 50mm Tool clamping length: 320 mm Feed profiling unit: 8 m/min Feed roller width: 50mm/35mm Feed roller diameter: 95 mm Stop height: 70 mm Working width: min. 30 mm; max. 220 mm Working height: min. 30 mm; max. 100mm Workpiece length without tenon: min. 245 mm Tool diameter max. For zero diameter 112 mm: 210 mm For zero diameter 140 mm: 232 mm Tool diameter max. (milling): 232 mm Tool zero flight circle: 112-140 mm Basic position under table: 10/5 mm Motor strength: Spindle: 11 KW Feed: 1.1 KW Feed profiling unit: continuously 6-12 m/min Feed roller width: 50 mm Feed roller diameter: 95 mm Stop height: 70 mm Working width: min. 30 mm; max. 220 mm Working height: min. 30 mm; max. 100mm Workpiece length without tenon: min. 245 mm Special equipment: 3 Mechanical spindle brake for synchronous spindle, profiling spindle and Additional aggregates SPINDLE 3 1 fitting milling unit, right: for milling the fitting groove in the Milling pass or for grooving in the longitudinal profile. Pneumatic horizontal movement with selector switch in the control panel. Motor power: 2.2 KW Speed: 6000 rpm Spindle diameter: 40mm Clamping height: 125 mm Tool flight circle: min. 140 mm; max. 180 mm Basic position below table level: 10 mm Motor reinforcement for synchronous spindle from 4 KW to 7.5 KW Motor reinforcement for profiling spindle from 5.5 KW to 11 KW Screen controls for 99 window types. 1 type can hold up to 8 different parts contain. Manufacturing options: individual parts, milling. Data entry via Keyboard with integrated operator guidance and error diagnosis. Free-standing control cabinet --------------------------------- (technical data according to manufacturer - no guarantee!)

6.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6828 · Outside profiling machine

Okoma - UF 2 EG mit Schleifeinheit - - gebraucht -

Technical details

1 OKOMA folding machine model UF 2 EG ------------------------------------- 1. Energy data: - Operating voltage: 3 phases, 380 V, 50 Hz. - Compressed air: Air requirement: 13 NL/min. Operating pressure: 8 bar up. Air: according to Pneurop 6611 2. Profile spindle 1: - Spindle arrangement: right - Power 11 kW - Speed ??7000 rpm - Direction of rotation: synchronous and counter rotation - Spindle diameter 40 mm - Usable length 252 mm - Tool diameter max. 230 mm - U-movement of the profile spindle - Positioning vertically Drive: pneumatic cylinder 120 mm cycle for 2 tool positions Position sensor: limit switch - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch - Automatic immersion: immersion speed can be regulated for tear-free Fold over - Protective and suction hood with connecting piece 140 mm diameter. 3. Profile spindle 2: - Spindle arrangement: right - Power 11 kW - Speed ??7000 rpm - Direction of rotation: counter rotation - Spindle diameter 50 mm - Usable length 272 mm - Tool diameter max. 230 mm - U-movement of the profile spindle - Positioning vertically Drive: pneumatic cylinder 90 mm cycle for 3 tool positions Position sensor: limit switch - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch - Protective and suction hood with connecting piece 140 mm diameter. 4. Fitting milling device EG: - Spindle arrangement on the right - Drive: three-phase motor 3 kW - Speed ??6000 rpm - Spindle diameter 30 mm - Usable length 47 mm - Vertical positioning: none - Positioning horizontally Drive: Pneumatic cylinder forward-back Position sensor: limit switch (rear only) - Protective and suction hood with connection piece 80mm diameter 5. Stop: - 1st stop: in front of spindle 1 manual chip removal Quick adjustment via. parallelogram - 2nd stop: between spindles 1 and 2 Chip removal: pneumatically adjustable - 3rd stop: after spindle 2 Fixed stop 6. Grinder with automatic immersion and immersion 7. Feed: - Roller distance from axle to axle 130 mm - Roll diameter 110 mm - Roll width 50 mm - Feed can be swiveled away - with pneumatic travel control 8. Support rail for milling: - Rail length: approx. 3000 mm - Adjustment range forward: approx. 100 - 600 mm 9. Electrical control: - Programmable logic controller: Siemens electronics PC control, 30 programs, 380 V., 50 Hz. - Power section: Siemens S 5 - Non-contact limit switches More pictures on request! --------------------------- (technical data according to manufacturer - no guarantee!)

5.000 €

Datasheet

Request / Contact

Roller conveyer

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

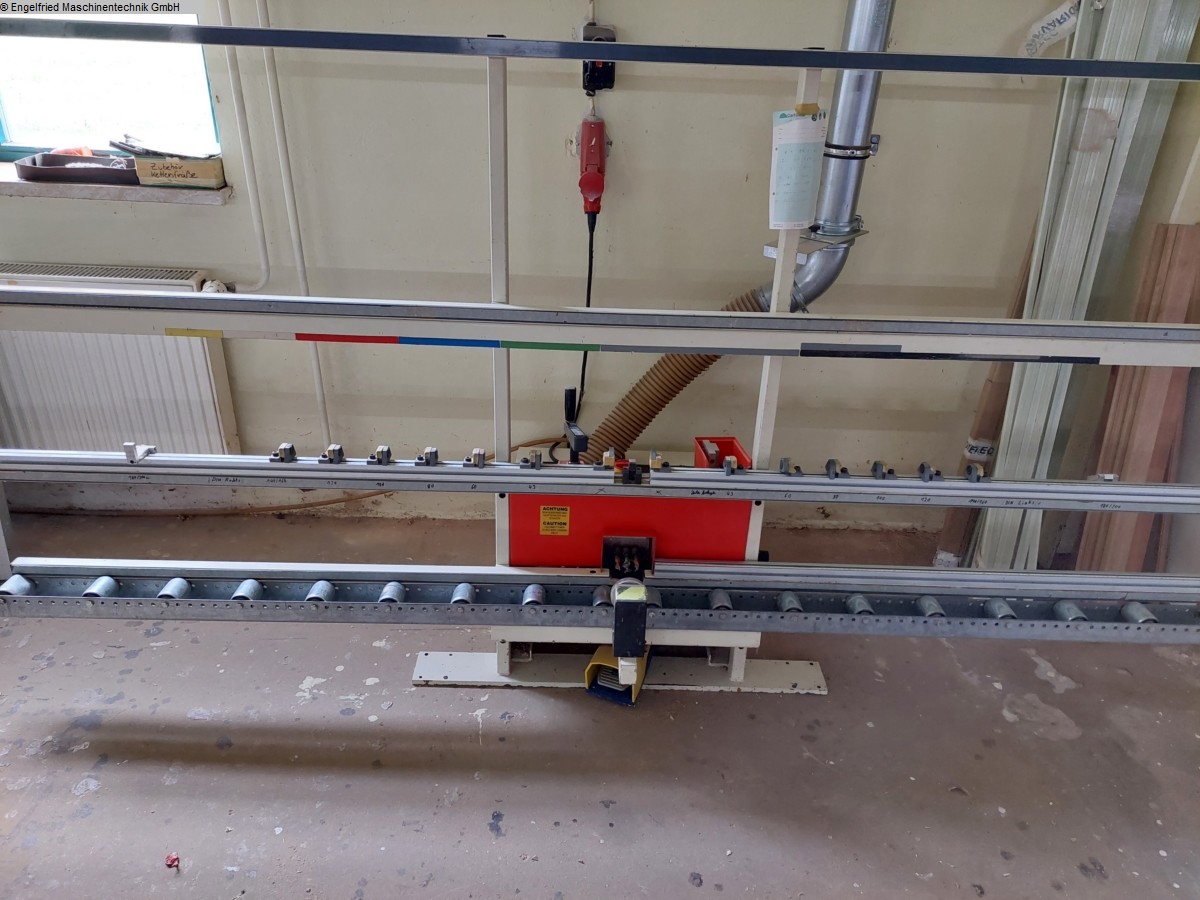

#1305-6788 · Roller conveyer

RUCHSER - Rollenbahn 4 Stk. - - gebraucht -

Technical details

4 pcs. roller conveyors 2000 x 200 x 1800 mm for internal and external processing

600 €

Datasheet

Request / Contact

Sanding machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6861 · Sanding machine

HESS - Junior - - gebraucht -

Technical details

Hess Junior single wood sander --------------------------------- basic structure: Stable, heavy welded construction made of thick-walled rectangular hollow profiles with additional, statically calculated bracing for optimal vibration damping. Staggered grinding units with large dimensioned Belt drive drums for slip-free belt travel. Two-point suction for direct and airborne dust extraction with integrated blow-off device. grinding units in heavy steel plate construction as the basis for vibration-damped, quiet belt run. All guides as a ball linear set on hardened and polished waves. Lasting precision thanks to protection against dust and dirt of the sphere linear sets. Contact roller and sanding pad in a balanced ratio to the grinding belt grain load. The large dimensioned drive drums guarantee the full transmission of the 5.5 kW drive power of the grinding motors on the grinding belt. This means the strongest chip removal possible. Automatic machine stop triggering if the tape breaks. Optical display on control panel. Sanding shoe for finish made of special material with optimal Heat dissipation and additional sliding lining. Easy to use pad change. Abrasive belt tension over appropriately dimensioned compression springs. Sanding belt relaxation for belt change by means of pneumatic Device for sensitive, distortion-free loading of new tapes. Upper Grinding unit and brush device (additional equipment) centrally motorized adjustable. Timber guide in the entry area for hard guide and guide rails supported on both sides pinch rollers. Tilt-proof transport of profiled workpieces calibrated conveyor belts with continuously adjustable feed rate. Automatic machine stop triggering by wood thickness control device. Optical display of the control panel. Infeed table via fine, precise threaded spindle for lower Grinding chip removal manually adjustable via scale (resolution 0.1 mm). The length Column table guidance guarantees an absolute parallel adjustment. The Adjustment of the flight circle to the outfeed table is achieved by adjusting the height of the lower one Grinding unit via precise threaded spindle and scale display (resolution 0.1 mm) accomplished. Clear, user-friendly arrangement of all electrical functional, operating and display elements on the front of the machine: grinding unit below, Grinding unit above, workpiece transport device, Grinding thickness setting, brushing device above/below, belt utilization, Operating display, fault display. All motors are against overload electrically secured. Technical specifications : --------------------------------- Sanding belt speed: 25 m/sec. Grinding width: 190 mm Grinding thickness: 4 - 150 mm Shortest workpiece length: 280 mm Feed speed, continuously adjustable 5 - 25 m/min. Sanding belt dimensions: 200 mm width, 1850 mm length Electrical equipment according to VDE Electrical connection : 400 V., 3/N, 50 Hz. Pneumatic connection: R 3/8", 6 bar, 80 NL grinding units: 2 x 5.5 kW feed: 0.75 kW height adjustment : 0.18 kW Pneumatic connection: R 3/8", 80 NL, min. 6 bar, max. 8 bar Extraction air quantity: 2 x 2000 to 2500 m3/h 20 - 25 m/sec. Extraction connection piece: 2 x 180 mm dia, on top of the machine housing External dimensions: without control cabinet 1750 mm wide, 1850 mm high, 1000 mm deep with control cabinet 1960 mm wide, 1850 mm high, 1000 mm deep Working height: 835 mm in the range of 4-20 mm only without guide rule Paint : RAL 7030 stone gray with RAL 1018 zinc yellow Additional equipment: 1 digital display for engine. grinding thickness adjustment 1 facility for Oscillation. Abrasive belt utilization device for oscillating Abrasive belt utilization to increase the service life of the abrasive belts and improvement of the surface finish by motor-driven adjustment of the grinding unit. Connection value: 0.12 kW, 380 V, 3/N, 50 Hz 1 brush and finish device, for better surface finish, integrated in the basic machine. Two special brush rollers 150 mm arranged one above the other Diameter in synchronism function to the feed. Separate height adjustment Brush rollers on precise carriage guides for post-wear correction. 1 pneumatic workpiece release device after brushing and finishing Furnishings Pictures and VIDEO shows machine of the same type (Technical data according to the manufacturer, without guarantee!)

4.000 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6870 · Sanding machine

LÖWER - Mini Spin N - - 2021 -

Technical details

Löwer edge finishing machine MiniSpin N Machines for finishing and intermediate sanding Edges and profiles with a grinding spindle horizontal or vertical. Motor 0.75 KW Spindle in vertical position for processing edges Spindle in horizontal position, swung out to the side for processing longer profile bars or similar or in Connection with a combination grinding head for grinding of edges with a sanding flap disc Grinding head can be swiveled +/- 20° for processing of slanted edges Working height / width 150 mm max. diameter roller / brush < 300 mm Frequency converter for continuous adjustment of the Spindle speed 200 - 800 rpm Table size 400 x 800 mm two directions of rotation selectable Operating voltage 110 / 240 V, 50 / 60 Hz Suction connection D=100 mm Weight approx. 100 kg including grooved base body D=180, L=150 with Smartflex sanding flaps CE version (technical data according to manufacturer - no guarantee!)

2.500 €

Datasheet

Request / Contact

Tenoning machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6835 · Tenoning machine

FESTO - ZA-101 - - gebraucht -

Technical details

Festo slotting machine ZA --------------------------- with crosscut saw 1 slotted spindle ZA length stop For sale on behalf of the customer in the IS condition!

500 €

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2700 · Tenoning machine

HABERKORN - FZS Studio - - gebraucht -

Technical details

Haberkorn FZS 1 Studio tenoning and slotting machine Machine is still being checked ------------------------------------------------------ The compact tenoning and slotting machine for the unusual window constructions. If you have the highest demands on a tenoning and slotting machine and easiest handling, you can meet them with the FZS 1 Studio right choice. This single shaft tenoning machine with 3 automatic tool positions contributes to reducing downtimes through quick tool changes and a special swivel table for the production of studio windows and segments for Arched window. The studio table developed for this purpose has special features that... enable rational work. Precise angle degree display via rotary encoder with 1/10 degree display. display in the control panel. The splinter wood stays in place at every angle setting Tool cutting plane. The support and thus the tension of the workpieces is always immediate the slotting tools. Automatic length compensation through special guideway and compensation attack. Length stop 2300 mm Quick lock at 90 degrees position. crosscut saw ------------------------------------------------------ Spindle arrangement: top Three-phase motor: 3 KW Spindle diameter: 30mm Speed: 2,800 rpm Saw blade diameter: max. 400 mm - automatic brake with speed monitoring - Positioning horizontally via pneumatic cylinders with turret heads - Protective and extraction hood with extraction nozzle 100 mm D Slotting spindle ------------------------------------------------------ Power: 7.5 KW Speed: 4,000 rpm Spindle diameter: 50mm Usable length: 300 mm Tool diameter max.: 400 mm Cycle 100 mm for 3 tool positions Protective and extraction hood with extraction nozzle 180 mm D Automatic brake with speed monitoring Special equipment: - Automatic trolley drive fully electronically controlled with automatic spindle lifting Trolley with stepless feed control depending on the area the crosscut saw and the slotting tools. - Lasers for precise display of the saw cut on the workpiece. On/off switch on the control panel. -LAS extension 1m extension of the dimension rail for subsequent installation. -LAS slider Length stop with 3 stop flaps for external frame dimensions and the associated external wing dimensions Weight: 850kg (technical data according to the manufacturer - no guarantee!)

5.500 €

Datasheet

Request / Contact

Transport system

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2361 · Transport system

WEINIG - DEF 25 - - gebraucht -

Technical details

Weinig pressure conveying system DEF 25 to the operator in working height for Unicontrol Length 2000 mm Depth 1800 mm Brand width 250 mm Rear roller conveyor not driven 2500 mm Roll width 250 mm (technical details according to manufacturer - without guarantee.)

2.500 €

Datasheet

Request / Contact

Window production centre

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6864 · Window production centre

WEINIG, GOETZINGER - UC 10, Univar, SFM - - gebraucht -

Technical details

Weinig Unicontrol 10-5, built in 1993 Slotted spindle 6 x 100 mm 2 profile spindles length 320 mm, stroke 95 mm Fitting spindle with folding device with return and discharge device Weinig Univar 10 with olive drilling rig, built in 1990 3 spindles each 320 mm long, stroke 95 mm + Fitting milling device Götzinger SFM, built in 2011 -------------------------------- Milling machine for the locking parts in the frame with 4 mm clearance + Drilling corner bearing Includes tools for Weinig Unicontrol: Zuani Tools IV 68/78/90 wood, 68/78 aluminum 4 mm clearance -------------------------------- For sale on behalf of the customer ex location Machines are currently still in use -------------------------------- (Technical information according to the manufacturer - no guarantee!)

10.000 €

Datasheet

Request / Contact

Window production line

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6869 · Window production line

Weinig, Gubisch, Panhans - PFA 17N, CW 2, kompl. Betrieb - - gebraucht -

Technical details

Company closure for wooden window construction -------------------------------------- Machines will be available from August/September 2024. Pos. 1: Weinig, PFA 17N, built in 1967 Four-sided planer, 6 spindles, chain drive, with glazing bead separation, with planing heads Continuous feed, working width 170 mm, working height 120 mm Electric height adjustment feed beam Pos. 2: MAPO Spu 180, built in 1992, finishing machine, mobile Pos. 3: Gubisch CW 2, built in 1998, angle system with return, with Leitz IV 68 wood, wood-aluminum; Gold IV 78 wood 1 slot spindle, 3 profile spindles Pos. 4: Götzinger OBM, built in 1998 corner bearing and olive drilling machine, 1 drill head Olive, 1 x drill head corner bearing Roto NT with left and right roller tables and stops, drilling on individual parts or glued frame Pos. 5: Panhans type 259, built in 1995, swivel spindle milling machine with extended support table and frame milling ruler, Feeder Hafffner 4 rollers, 3000/4000/5000/6000 rpm Pos. 6: Panhans type 690, built in 1991, panel saw with swiveling saw blade, with cross stop Pos. 7: Elumatec type DG 79, built in 1998, double miter saw 3 m Pos. 8: Hema band saw, mobile Pos. 9:Rapid chain milling machine Pos. 10: Klein and Söhne, combined jointer and thickness planer Pos. 11: Hofmann Dübelfix DBL, drilling machine Pos. 12: Hess Presse pneumatic Pos. 13: Filter house with silo, filter system, fan Pos. 14:Spänex SHB 50-250-SPS, built in 1998 briquetting press with automatic control Pos. 15:Spänex return air duct for summer/winter operation, return air ceiling filter -------------------------------------- Total price from location: 30,000.00 euros Machines must be dismantled and loaded by the buyer himself. Subject to errors and prior sale.

30.000 €

Datasheet

Request / Contact

plants

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

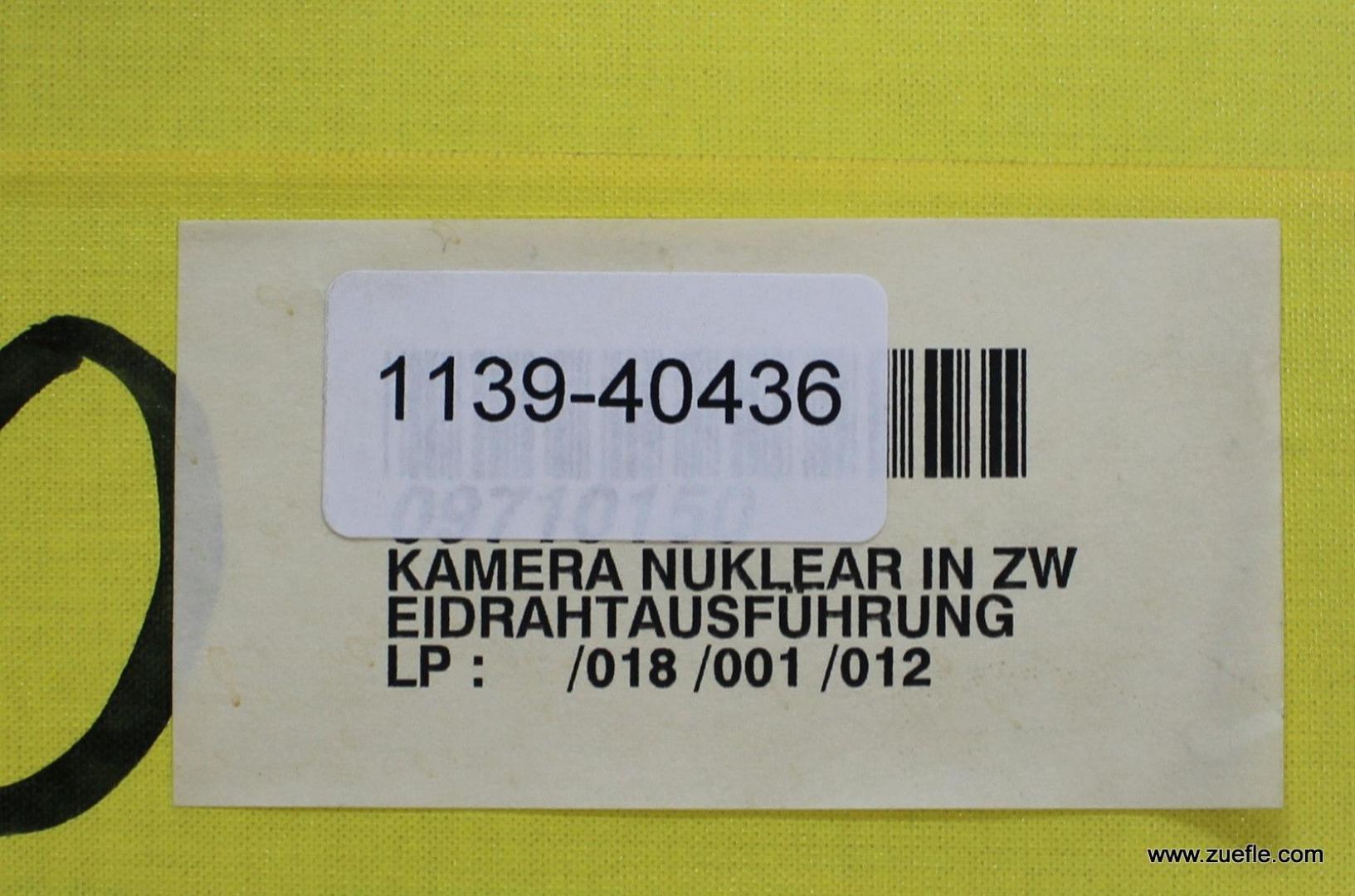

#1139-00399 · plants

GRUNDIG - FA 76 NU - - - konventionell

Technical details

GRUNDIG Two-wire version nuclear camera FA 76 NU Article no. 9.43020-1304 12VDC 22W with adjustment socket ES76 with guide plate FP70 with 30-pin coupling plug NU with connection plate AP76 in protective housing with mounting kit for cable seal AP76 You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

cooling plants food technology

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-LS7009 · cooling plants food technology

Thermofin GmbH (Hans Günter Gm - S-GGHF 045.1D/24-AW/8P - - 29.09.2004 - PC

Technical details

Thermofin GmbH (Hans Günter GmbH) Evaporator without refrigeration unit. Is filled with the refrigerant R134A. The unit can be inspected in the Ulm area. Make an appointment.

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-LS7010 · cooling plants food technology

Thermofin GmbH (Hans Günter Gm - S-GGF045D/24 - - 1999 - PC

Technical details

Food Machines - Diverse

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

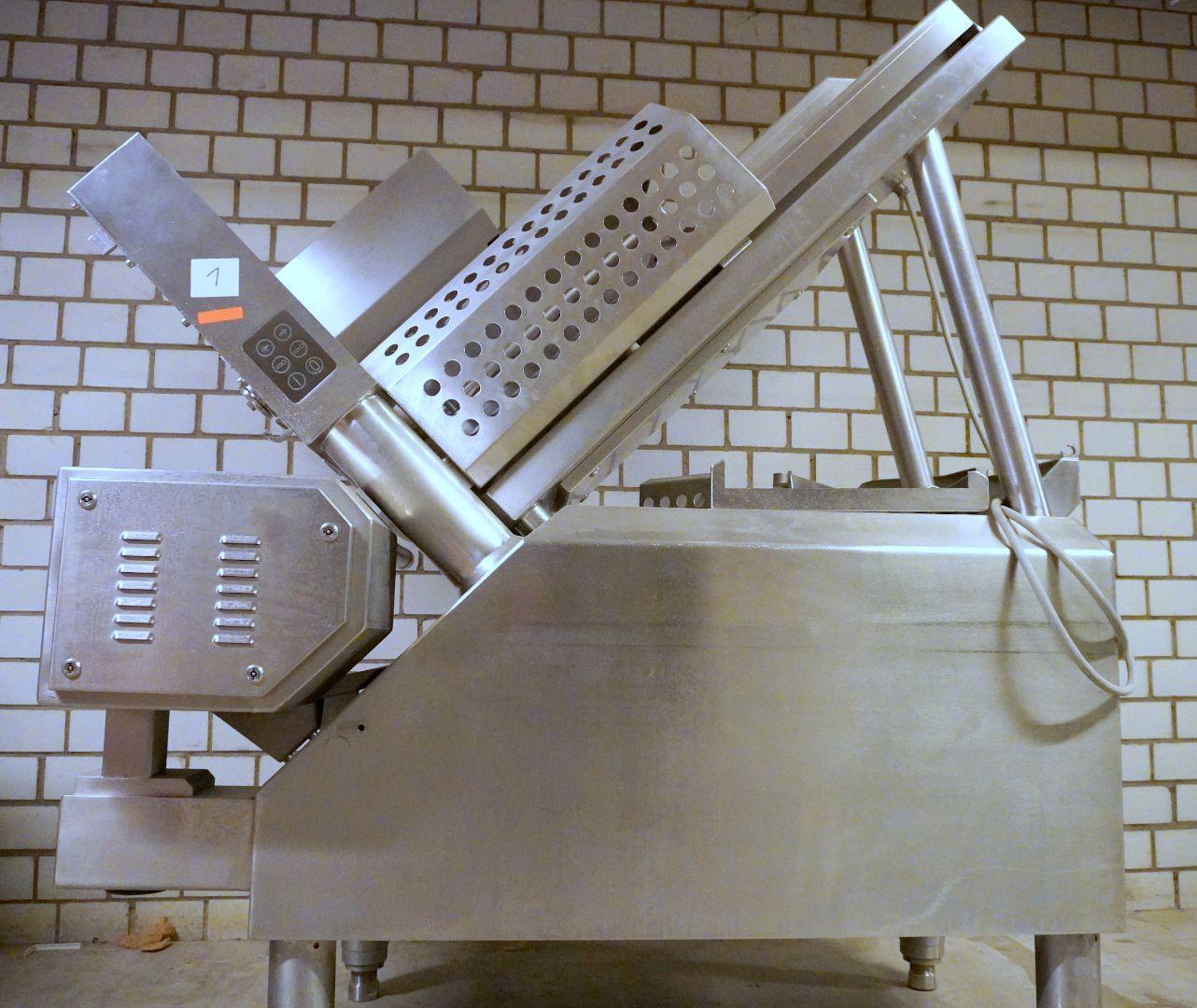

#1139-LS7003 · Food Machines - Diverse

WEBER - SLC 501 - - 2003 - PC

Technical details

Weber slicer with complete weighing line High-performance slicer and portioning machine with a complete complete weighing line for equally weighted portions consisting of: Computer slicer CCS 501 SLC MPS 2 control system - in stainless steel design - Cutting capacity: max. 500 cuts per minute - Circular knife ø: 460 mm - Slice thickness: approx. 0.1 - 50 mm - Product size: max. 135 x 250 mm (height x width) - Product length: max. 1,000 mm - Circular cutter head SK 144 with speeds from approx. 50 to 500 revolutions per minute. - Electricity: 400 Volt, 50 Hz, 7 kW in addition - a portioning belt for stacking and shingling, belt length approx. 170 mm, version with flat belt, version with transfer needles. - Control belt for speed-controlled transfer of the portions, belt length approx. 310 mm, version with round belt. 1 circular knife, Ø 460 mm 1 knife transfer device 1 product holder, pneumatic Continuous checkweigher WE 1000 - Digital weighing system with a transport speed of approx. of approx. 1.0 m per second. System carrier in stainless steel. - Solo scale standard, scale 485 mm, table width approx. 375 mm. - Throughput: max. approx. 100 weighings/min (depending on portion) - max. portion weight approx. 1,000 g - Weighing table with round belt Rocker CCR 5440 Three-position rocker in stainless steel housing Mono rocker Slicer with weighing line Weber CCS 501 SLC Rocker length approx. 450 mm, rocker width approx. 380 mm, version with flat belt. Conveyor belt CCE Stationary conveyor belt with solid machine housing. Conveyor belt for the sliced portions from the slicer to the packaging machine. packaging machine. The belt can be easily removed from the belt frame without tools. The transport speed is controlled by the slicer. The conveyor belt can optionally be equipped with a tilting end piece as well as with a sorting belt. Conveyor belt length including tensioning piece, approx. 2,600 mm Table extension of the infeed belt fixed. Sorting belt top, length approx. 1,600 mm Height of the belts fixed. The unit can be inspected under power in the Ulm area. Make an appointment.

33.700 €

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-LS7001 · Food Machines - Diverse

Diosna - HKV 224 Hebekipper - - 2003 - PC control

Technical details

Diosna HKV 224 lifting tipper We offer a Diosna HKV 224 lifting tipper for the food industry, especially in the area of dough processing. The system built in 2003 is fully functional and can be demonstrated under power. We would also be happy to provide you with a video. Come to visit the facility near Ulm / South Germany

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-LS7008 · Food Machines - Diverse

MAREL TVM - TVM - Portio 4000 - - 04.1999 - PC

Technical details

10.700 €

Datasheet

Request / Contact

Frequency Changer

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00363 · Frequency Changer

REXROTH - PSI 6200.100 W1 - - 2015 - konventionell

Technical details

REXROTH frequency inverter featuring an integrated cooling system PSI6200 Type PSI 6200.100 W1 MNR: 1070081748 GC1 UN = 400-480VAC IN = 230A with extension module 15W07 ICBHT MNR: 1070091803 I/O DISK_K with Ethernet CC/100MBAUD 12W12 R911307969-GB1 ICBHT MAC ID: 00-30-11-06-AC-C7 Welding control system for resistance welding e.g. with robots or on projection welding machines previously used for NIMAK system medium frequency inverter used Weight 37.5kg Very good condition You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

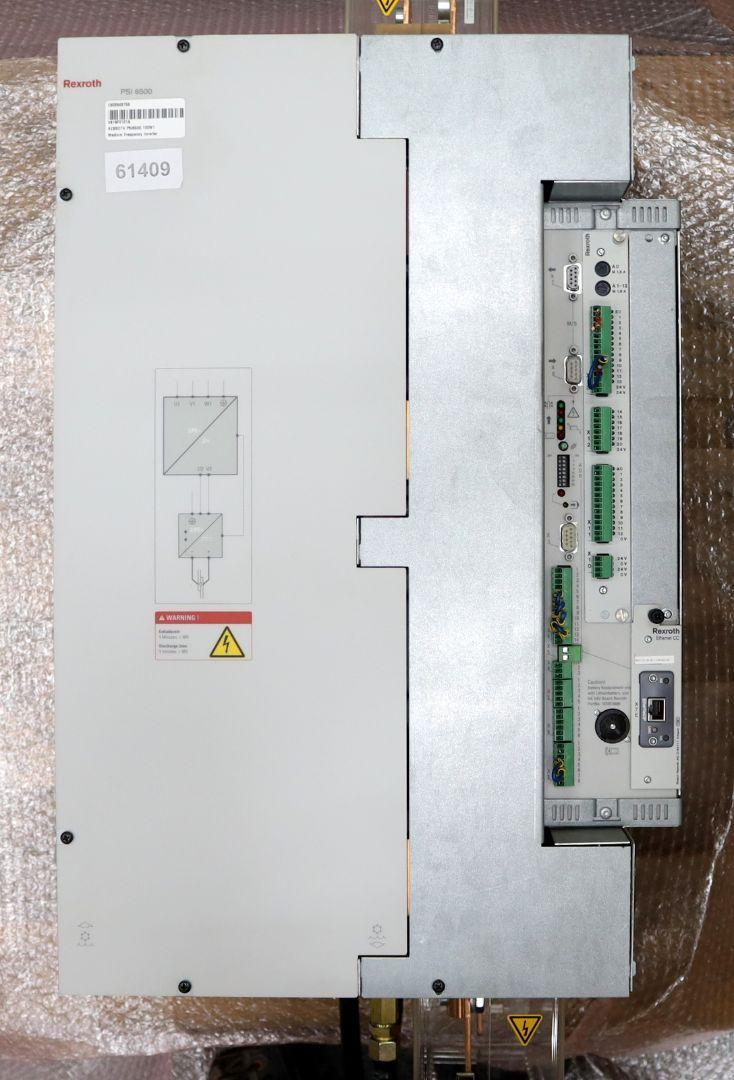

#1139-00352 · Frequency Changer

REXROTH - PSI 6500.100.W1 - - 2013 - konventionell

Technical details

REXROTH frequency inverter PSI6500 Type PSI 6500.100.W1 MNR: 1070079302-306 GG1 UN = 400-480VAC IN = 660A with extension module I/O DISK_K 13W47 ICBHT 1070091803-AC1 with Ethernet CC/100MBAUD 12W12 R911307946-GB1 ICBHT MAC ID: 00-30-11-06-AC-C5 Welding control for resistance welding e.g. with robots or on projection welding machines previously used for NIMAK system medium frequency inverter used Weight 60.8kg Very good condition You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-00362 · Frequency Changer

REXROTH - PSI 6200.100 W1 - - 2012 - konventionell

Technical details

REXROTH frequency inverter featuring an integrated cooling system PSI6200 Type PSI 6200.100 W1 MNR: 1070081748 GC1 UN = 400-480VAC IN = 230A with extension module 12W05 ICBHT I/O DISK_K 1070091803-AC1 with Ethernet CC/100MBAUD R911307946-GB1 MAC ID: 00-30-11-06-AC-C7 Welding control system for resistance welding e.g. with robots or on projection welding machines previously used for NIMAK system medium frequency inverter used Weight 37.5kg Very good condition You can come and inspect the article at our warehouse in Giebelstadt about 80min. from FRANKFURT AIRPORT.